In electronic component manufacturing, box-type resistance furnaces are indispensable tools for a range of critical thermal processes. They are used for foundational semiconductor steps like oxidation and annealing, for sintering advanced electronic ceramics such as multilayer ceramic capacitors (MLCCs), and for final assembly processes like chip packaging.

The reliability of modern electronics hinges on precise thermal processing. Box-type resistance furnaces provide the controlled, uniform high-temperature environments necessary to create specific material properties, from insulating layers on silicon wafers to the dense structures of advanced ceramics.

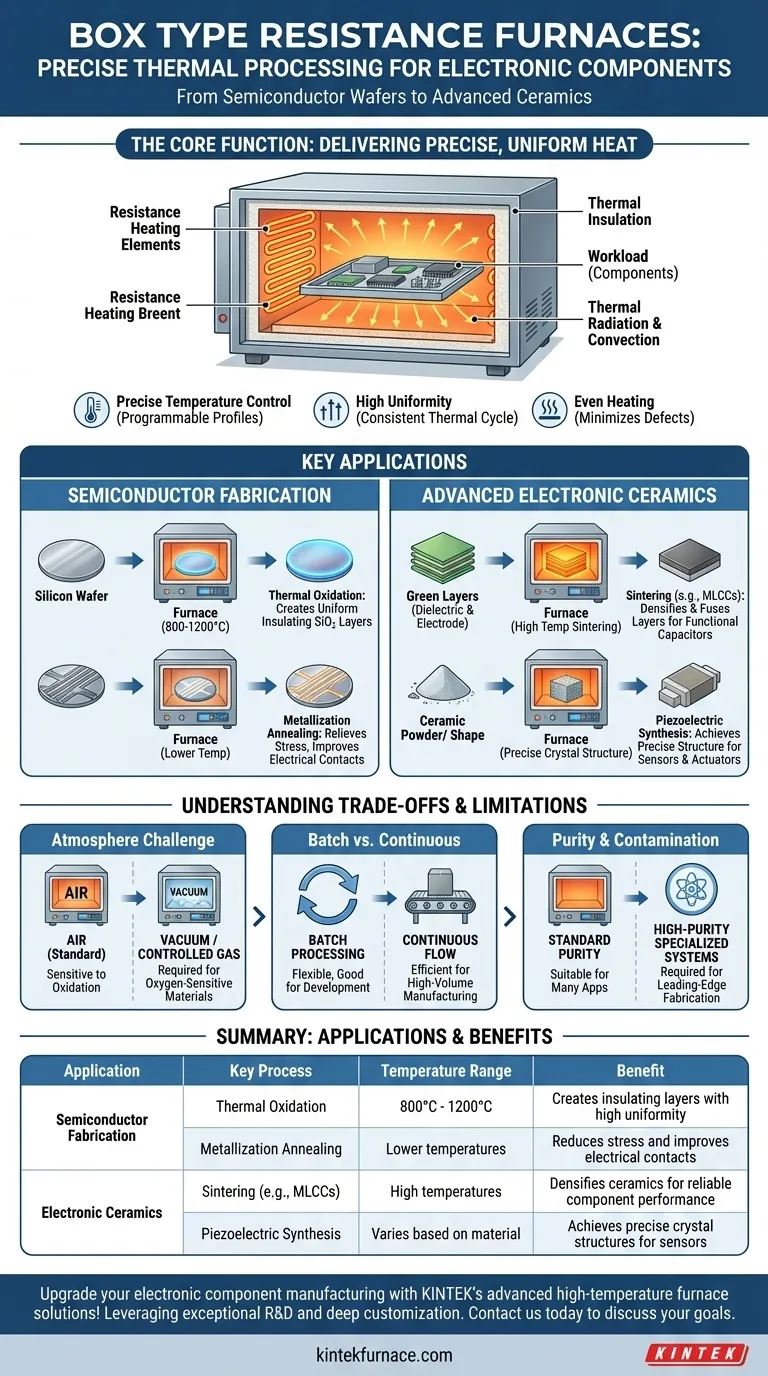

The Core Function: Delivering Precise, Uniform Heat

A box-type resistance furnace is fundamentally a thermally insulated chamber that uses resistive heating elements to generate high temperatures. Its value in electronics manufacturing comes from its ability to deliver this heat with exceptional control.

How Resistance Furnaces Work

The principle is straightforward: electric current flows through resistance wires or elements, generating heat. This heat is then transferred to the components inside the furnace chamber through thermal radiation and convection, ensuring the entire workload is heated evenly.

Why Temperature Uniformity is Non-Negotiable

For electronic components, especially across a large silicon wafer or a tray of capacitors, even small temperature variations can lead to significant defects. High temperature uniformity ensures that every part of every component undergoes the exact same thermal cycle, resulting in consistent, reliable material properties.

The Importance of Programmable Control

Manufacturing processes like annealing or sintering require specific temperature profiles—precise rates of heating, holding at a target temperature (soaking), and controlled cooling. The flexible, programmable nature of these furnaces allows engineers to execute these complex thermal recipes perfectly.

Key Applications in Semiconductor Fabrication

In the front-end stages of semiconductor manufacturing, these furnaces are used to build the foundational structures of an integrated circuit.

Creating Insulating Layers: Thermal Oxidation

To create a high-quality, electrically insulating layer of silicon dioxide (SiO₂), silicon wafers are heated in a furnace to temperatures between 800°C and 1200°C. This process, known as thermal oxidation, grows a uniform oxide layer that is critical for transistor function.

Optimizing Metal Layers: Metallization Annealing

After thin metal films (like aluminum) are deposited onto a wafer, internal stresses can exist. Metallization annealing is a lower-temperature heat treatment that relieves this stress, improves the film's structural integrity, and reduces the electrical contact resistance between metal and silicon layers.

Manufacturing Advanced Electronic Ceramics

Many essential passive components are made from ceramic materials that require high-temperature processing to achieve their desired electronic and physical properties.

Building Multilayer Ceramic Capacitors (MLCCs)

MLCCs are created by stacking layers of ceramic dielectric and metal electrodes. This "green" structure is then heated in a furnace in a process called sintering, which densifies the ceramic and fuses the layers together to create a monolithic, functional capacitor.

Producing Piezoelectric Components

Materials like lead zirconate titanate (PZT) exhibit piezoelectric properties, meaning they generate a voltage when stressed. The synthesis and sintering of these specialized ceramics are performed in box furnaces to achieve the precise crystal structure required for their function in sensors and actuators.

Understanding the Trade-offs and Limitations

While versatile, the standard box-type resistance furnace is not the solution for every thermal process. Understanding its limitations is key to proper application.

The Atmosphere Challenge: Air vs. Controlled Atmosphere

A standard box furnace operates with a normal air atmosphere. For processes that are sensitive to oxygen, such as treating easily oxidized materials, this is a significant limitation. In these cases, a vacuum furnace or a controlled-atmosphere furnace (using inert gases like nitrogen or argon) is required.

Batch Processing vs. Continuous Flow

By their nature, box furnaces are designed for batch processing. You load a batch of components, run the thermal cycle, and then unload them. This is ideal for development, testing, or moderate production volumes but is less efficient for high-volume manufacturing, which often relies on continuous or inline furnaces.

Purity and Contamination Risks

While excellent for many applications, the highest-end semiconductor fabrication may require furnaces with specialized construction materials and handling systems to prevent even trace amounts of contamination. A general-purpose box furnace may not meet the stringent purity requirements of a leading-edge cleanroom.

Making the Right Choice for Your Goal

Selecting the correct thermal equipment depends entirely on the material, process, and production goals.

- If your primary focus is foundational semiconductor processing like oxidation or annealing: A furnace with exceptional temperature uniformity and precise, programmable control is non-negotiable.

- If your primary focus is producing electronic ceramics like MLCCs: You need a furnace capable of reaching the high sintering temperatures required for your specific ceramic material while maintaining uniformity.

- If your primary focus is high-purity or oxygen-sensitive processes: You must look beyond a standard box furnace to a specialized vacuum or controlled-atmosphere system.

Ultimately, mastering thermal processing by selecting the appropriate furnace is a foundational step in manufacturing reliable and high-performance electronic components.

Summary Table:

| Application | Key Process | Temperature Range | Benefit |

|---|---|---|---|

| Semiconductor Fabrication | Thermal Oxidation | 800°C - 1200°C | Creates insulating layers with high uniformity |

| Semiconductor Fabrication | Metallization Annealing | Lower temperatures | Reduces stress and improves electrical contacts |

| Electronic Ceramics | Sintering (e.g., MLCCs) | High temperatures | Densifies ceramics for reliable component performance |

| Electronic Ceramics | Piezoelectric Synthesis | Varies based on material | Achieves precise crystal structures for sensors |

Upgrade your electronic component manufacturing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and product reliability. Contact us today to discuss how we can support your thermal processing goals!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What technical requirements affect the external thermal strength of furnace tubes? Optimize for High-Temp Performance

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What happens to convective and radiative heat transfer effects at high furnace gas temperatures? Radiation Dominates for Superior Heating

- What factors should be considered when purchasing a quartz tube furnace? Ensure Reliable High-Temperature Processing

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing