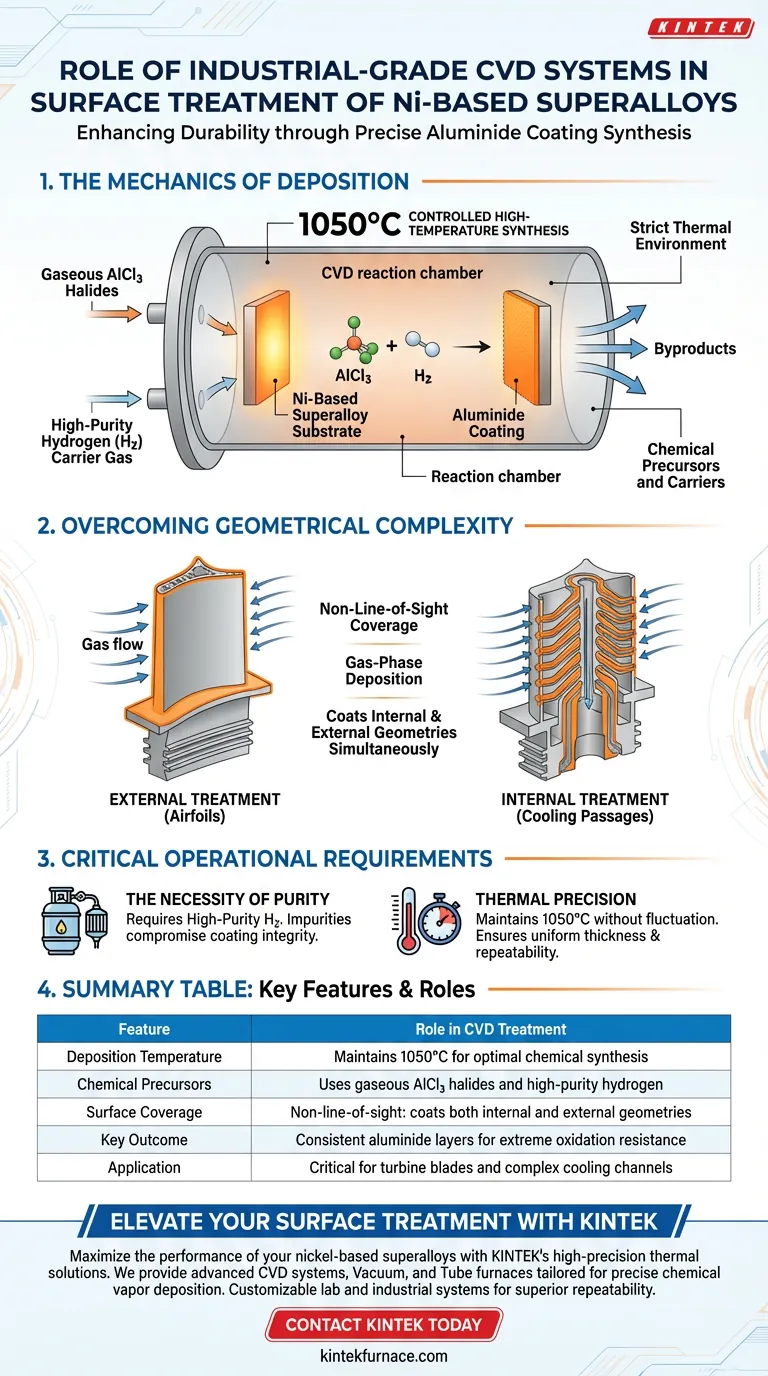

An industrial-grade CVD system serves as the critical reaction chamber for enhancing the durability of nickel-based superalloys. Its primary role is to synthesize aluminide coatings by reacting gaseous aluminum halides (AlCl3) with high-purity hydrogen at extremely high temperatures (1050°C). This process ensures that protective aluminum layers are deposited with precision, creating a barrier that protects the underlying alloy.

The system solves the challenge of coating complex geometries by using gas-phase deposition to treat both internal cooling channels and external surfaces simultaneously, guaranteeing consistent thickness and production repeatability.

The Mechanics of Deposition

Controlled High-Temperature Synthesis

The industrial CVD system provides a strictly regulated thermal environment essential for chemical bonding.

It maintains a specific reaction temperature of 1050°C.

At this temperature, the thermodynamic conditions are ideal for synthesizing aluminide coatings directly onto the nickel-based substrate.

Chemical Precursors and Carriers

The system does not simply coat the part; it facilitates a chemical reaction using specific agents.

It utilizes gaseous AlCl3 halides as the primary source of aluminum.

To transport this aluminum to the surface of the alloy, the system employs high-purity hydrogen as a carrier gas.

Overcoming Geometrical Complexity

Non-Line-of-Sight Coverage

Unlike physical spray methods, the CVD system utilizes gas flow to deliver coating materials.

This allows the aluminum to reach areas that are not in the direct line of sight of an applicator.

Internal vs. External Treatment

The most distinct advantage of this system is its ability to coat complex components like turbine blades comprehensively.

It deposits aluminum uniformly on external surfaces (airfoils).

Simultaneously, it coats the internal surfaces (cooling passages), ensuring the entire component is protected against oxidation and corrosion.

Critical Operational Requirements

The Necessity of Purity

While the system is powerful, it demands rigorous input quality to function correctly.

The reference emphasizes the use of high-purity hydrogen.

Using gases with impurities can compromise the integrity of the aluminide coating and the substrate bond.

Thermal Precision

The specific temperature of 1050°C is not a suggestion; it is a synthesis requirement.

The industrial-grade nature of the system is defined by its ability to hold this temperature without fluctuation.

Inconsistent heat distribution would lead to uneven coating thickness and reduced repeatability in a production environment.

Making the Right Choice for Your Goal

If you are evaluating surface treatment options for nickel-based superalloys, consider your specific constraints:

- If your primary focus is complex geometry: The CVD system is essential for coating internal channels and blind holes that line-of-sight methods cannot reach.

- If your primary focus is process consistency: An industrial-grade system is required to maintain the strict 1050°C environment needed for high production repeatability.

By leveraging gas-phase reactions at precise temperatures, industrial CVD systems turn standard superalloys into high-performance components capable of surviving extreme operational stress.

Summary Table:

| Feature | Role in CVD Treatment of Ni-Based Superalloys |

|---|---|

| Deposition Temperature | Maintains 1050°C for optimal chemical synthesis |

| Chemical Precursors | Uses gaseous AlCl3 halides and high-purity hydrogen |

| Surface Coverage | Non-line-of-sight: coats both internal and external geometries |

| Key Outcome | Consistent aluminide layers for extreme oxidation resistance |

| Application | Critical for turbine blades and complex cooling channels |

Elevate Your Surface Treatment with KINTEK

Maximize the performance of your nickel-based superalloys with KINTEK’s high-precision thermal solutions. Backed by expert R&D and world-class manufacturing, we provide advanced CVD systems, Vacuum, and Tube furnaces tailored for precise chemical vapor deposition and high-temperature synthesis. Whether you need uniform internal coatings for complex turbine geometries or superior thermal stability at 1050°C, our customizable lab and industrial systems deliver the repeatability your project demands.

Ready to optimize your material durability? Contact KINTEK today for a consultation!

Visual Guide

References

- Effect of Ni-Based Superalloy on the Composition and Lifetime of Aluminide Coatings. DOI: 10.3390/ma18133138

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

People Also Ask

- What are the technical advantages of using an LPCVD system for WS2-MoS2? Achieve Atomic Seamless Precision

- What are the key differences between PVD and CVD processes? Choose the Right Thin-Film Deposition Method

- What is Chemical Vapor Deposition (CVD) and where is it commonly used? Key Applications and Benefits

- How can customers maximize the quality of CVD coatings? Master Pre-Coating Prep for Superior Results

- What is Chemical Vapor Deposition (CVD) and what is its primary function? | Enhance Materials with Precision Coatings

- What process conditions does CVI equipment provide for optimizing ceramic honeycombs? Enhance Microwave Absorption

- What are the economic advantages of an integrated CVD carbonization system? Save 90% in Production Time

- What are the advantages of CVD? Achieve Unmatched High-Purity, Conformal Thin Films