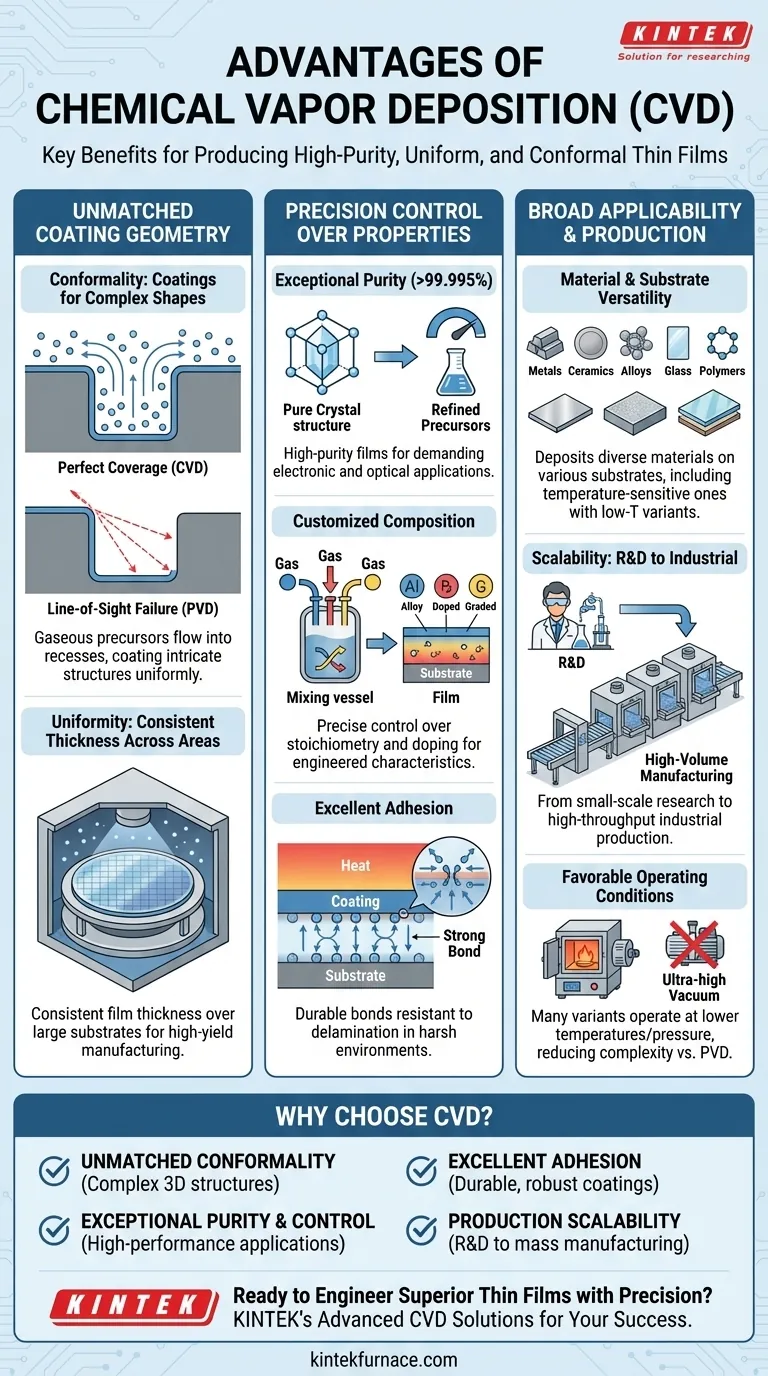

At its core, Chemical Vapor Deposition (CVD) is a process renowned for its ability to produce exceptionally high-purity, uniform, and conformal thin films. Its key advantages are the capability to coat complex three-dimensional surfaces evenly, the wide versatility of materials that can be deposited, and the precise control it offers over the final film's thickness and composition. This makes it a foundational technology in demanding fields like semiconductors and aerospace.

The true power of CVD lies not just in creating a coating, but in its ability to grow a high-performance film atom-by-atom. This allows it to conform perfectly to intricate geometries where line-of-sight methods would fail, enabling the function of countless modern technologies.

The Foundation: Unmatched Coating Geometry

The most significant advantage of CVD stems from its use of gaseous precursors. Unlike line-of-sight processes like sputtering, these gases can flow into, around, and within complex structures, ensuring a uniform coating.

The Power of Conformality

Conformality is the measure of a coating's ability to maintain a uniform thickness across a varied surface. Because CVD precursors are gases, they can diffuse into deep trenches, recesses, and small holes on a substrate.

The chemical reaction then occurs on all exposed surfaces simultaneously. This results in a film that perfectly replicates the underlying topography, which is critical for fabricating microelectronics and coating intricate medical or aerospace components.

Uniformity Across Large Areas

Beyond individual features, CVD provides excellent uniformity over large substrates, such as silicon wafers. By carefully controlling gas flow, temperature, and pressure within the reaction chamber, the process ensures that the film thickness is consistent from the center to the edge of the substrate.

This level of consistency is essential for achieving reliable yield in high-volume manufacturing.

Precision Control Over Material Properties

CVD is not a "one-size-fits-all" process. It offers engineers a high degree of control over the final product's characteristics by manipulating the inputs.

Attaining Exceptional Purity

The process is inherently self-cleaning and uses highly refined precursor gases, allowing for the deposition of extremely pure films—often exceeding 99.995% purity.

This level of purity is non-negotiable for applications where trace impurities could degrade electrical, optical, or chemical performance, such as in semiconductor devices or high-performance optical coatings.

Customizing Film Composition

By mixing different precursor gases or changing them during deposition, you can precisely control the film's composition and stoichiometry. This allows for the creation of alloys, doped films, or graded layers where properties change with depth.

This customization enables the engineering of films with specific characteristics, such as hardness, electrical conductivity, corrosion resistance, or lubricity.

Creating Strong, Adhesive Bonds

The CVD process typically occurs at elevated temperatures, which promotes diffusion and chemical bonding between the film and the substrate material. This results in a coating with excellent adhesion that is highly durable and resistant to delamination, even in high-stress or thermally demanding environments.

Broad Applicability and Production Readiness

CVD is a mature and versatile technology that has proven to be effective for both specialized research and large-scale industrial production.

Versatility in Materials and Substrates

CVD can be used to deposit a vast range of materials, including metals, ceramics (oxides and nitrides), and alloys.

Furthermore, it can be applied to a wide variety of substrate materials, from metals and ceramics to glass and, with low-temperature variants, even some polymers.

Scalability for Industrial Production

The process is highly scalable, with systems available for everything from small-scale research and development to fully automated, high-throughput manufacturing. Its relatively high deposition rates and reliability make it economically viable for industrial production.

Favorable Operating Conditions

While some CVD processes require high temperatures, many variants operate at lower temperatures or atmospheric pressure. Critically, most CVD processes do not require the ultra-high vacuum conditions needed for technologies like Physical Vapor Deposition (PVD), which can simplify equipment design and reduce cost.

Understanding the Trade-offs

No technology is without its limitations. To make an informed decision, it is critical to weigh the advantages of CVD against its potential challenges.

Precursor Management

The precursor chemicals used in CVD can be toxic, flammable, or corrosive. Safely handling, storing, and disposing of these materials requires specialized infrastructure and strict safety protocols, adding to the operational complexity and cost.

Process Temperature

Traditional CVD often operates at high temperatures (several hundred to over a thousand degrees Celsius). While this promotes high-quality films and strong adhesion, it can limit the choice of substrates to those that can withstand the thermal load without warping or degrading. Low-temperature alternatives like PECVD (Plasma-Enhanced CVD) exist but can introduce their own complexities.

Byproduct Formation

The chemical reactions in CVD inevitably produce byproducts that must be managed. These byproducts can deposit on chamber walls, requiring periodic cleaning, or need to be scrubbed from the exhaust stream, adding another layer to process management.

Making the Right Choice for Your Goal

Selecting the right deposition technology depends entirely on your primary objective and constraints.

- If your primary focus is coating complex 3D microstructures: CVD is the superior choice, as its inherent conformality is unmatched by line-of-sight techniques.

- If your primary focus is creating ultra-pure, defect-free films: CVD's use of high-purity precursor gases provides a distinct advantage for high-performance electronic and optical applications.

- If your primary focus is coating temperature-sensitive materials like plastics: You must carefully consider low-temperature CVD variants or explore alternative technologies like PVD, as traditional CVD processes are likely too hot.

- If your primary focus is depositing a simple metal film on a flat surface at low cost: A simpler technology like sputtering or evaporation may be more cost-effective and sufficient for the task.

Understanding these core advantages empowers you to select the right tool for engineering materials with precision and purpose.

Summary Table:

| Key Advantage | Core Benefit |

|---|---|

| Unmatched Conformality | Uniform coating on complex 3D geometries, trenches, and recesses. |

| Exceptional Purity & Control | High-purity films (>99.995%) with precise control over composition and thickness. |

| Excellent Adhesion | Strong, durable bonds resistant to delamination in demanding environments. |

| Broad Material Versatility | Deposit metals, ceramics, and alloys on various substrates. |

| Production Scalability | Scalable from R&D to high-throughput industrial manufacturing. |

Ready to Engineer Superior Thin Films with Precision?

If your project demands high-purity, conformal coatings for complex components in semiconductors, aerospace, or advanced research, KINTEK's advanced CVD solutions are engineered for your success.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Contact our experts today to discuss how our CVD technology can bring unparalleled precision and performance to your application.

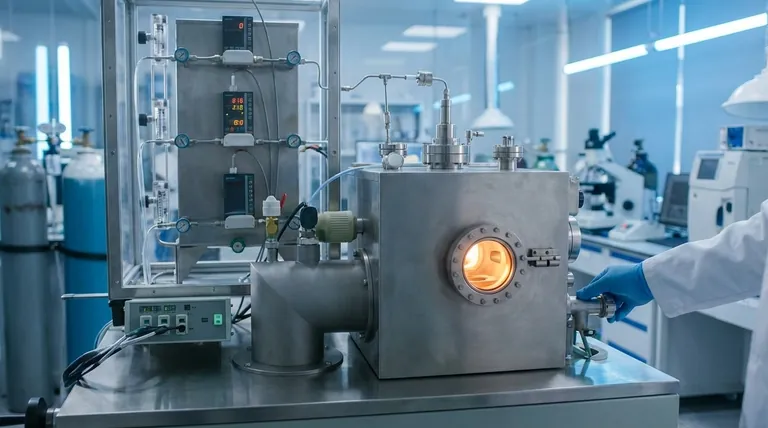

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

People Also Ask

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials

- What gases are used in chemical vapor deposition? Master Precursor & Process Gases for Superior Films

- What is the necessity of high-bias gas ion cleaning? Achieve Atomic-Level Coating Adhesion

- What methods are used to analyze and characterize graphene samples? Unlock Key Techniques for Accurate Material Analysis

- Why Use PECVD for Monolithic Integrated Chip Isolation Layers? Protect Your Thermal Budget with High-Quality SiO2