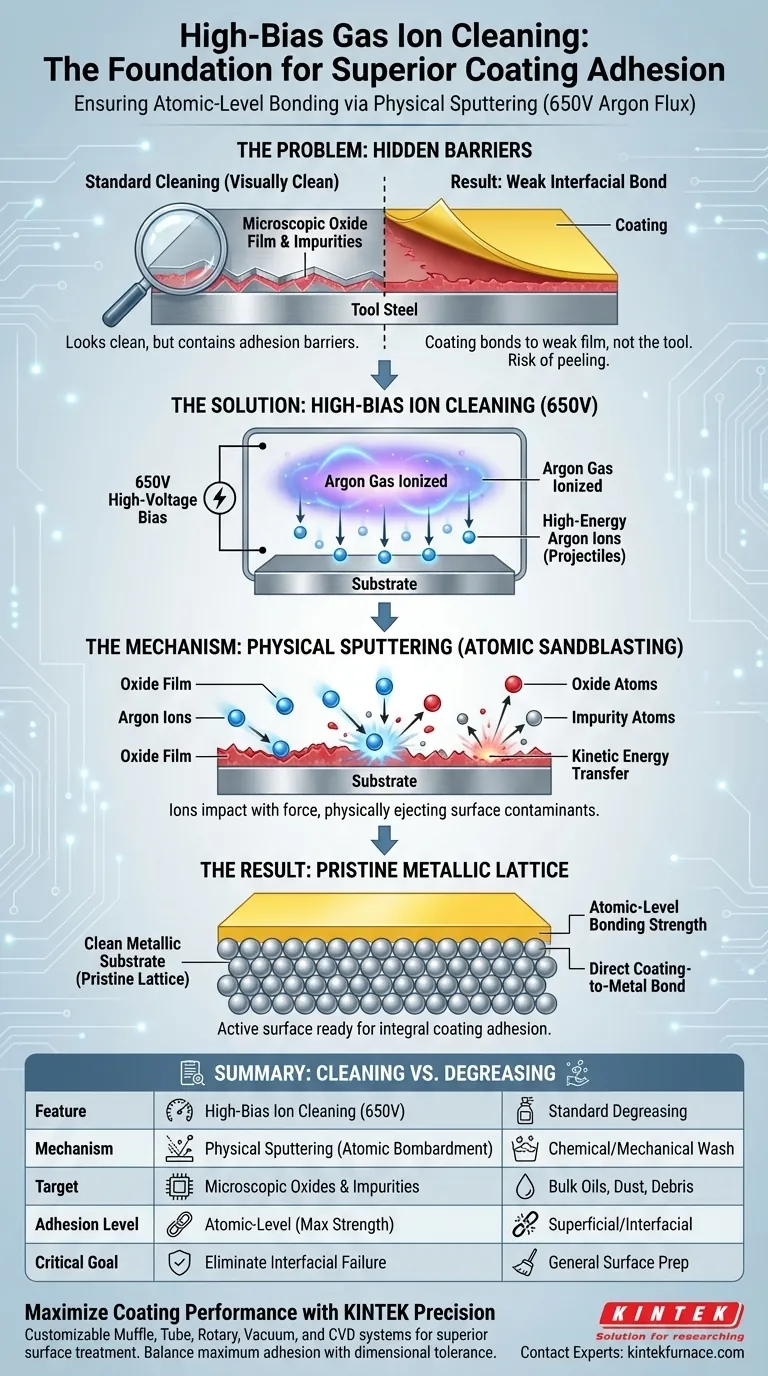

The necessity of high-bias gas ion cleaning lies in its ability to ensure coating adhesion through atomic-level surface preparation. By subjecting the substrate to a high-energy argon ion flux at 650V, the process utilizes physical sputtering to strip away residual oxide films and impurities. This creates a chemically active, pristine metallic surface that allows subsequent coating layers to bond directly to the base material rather than to weak surface contaminants.

Core Takeaway: A surface may look clean to the naked eye but still possess a microscopic oxide layer that acts as a barrier to adhesion. High-bias ion cleaning is the critical "atomic sandblasting" step that removes this barrier, enabling the maximum possible bonding strength between the coating and the tool steel.

The Mechanism of Physical Sputtering

Utilizing High-Voltage Argon Flux

The process relies on establishing a high-bias environment, specifically conducting the cleaning at 650V.

In this environment, argon gas is ionized, creating a flux of high-energy ions. These ions are accelerated toward the tool steel surface with significant force.

Impact-Driven Material Removal

This is not a chemical wash; it is a mechanical process known as physical sputtering.

The argon ions bombard the surface like microscopic projectiles. Upon impact, they transfer enough kinetic energy to physically eject (sputter) atoms from the substrate’s surface, effectively blasting away unwanted material.

Why "Clean" Isn't Clean Enough

Eliminating Residual Oxide Films

Even after standard washing and degreasing, tool steel naturally retains a thin, often invisible layer of oxidation.

If left in place, this oxide film acts as an intermediate layer between the tool and the coating. Because oxides often have weak structural integrity, the coating would essentially be bonded to a "crumbly" surface rather than the solid tool.

Exposing the Metallic Lattice

The primary goal of the 650V ion bombardment is to expose the clean metallic substrate.

By removing the impurities and oxides, the process reveals the true lattice of the tool steel. This exposure is non-negotiable for achieving atomic-level bonding strength, ensuring the coating becomes an integral part of the tool rather than a superficial shell.

Understanding the Trade-offs

High Energy vs. Substrate Integrity

While high bias (650V) is necessary for thorough cleaning, it represents a significant energy input.

The bombardment creates heat and removes a small amount of the substrate material itself. It is essential to control the duration to avoid overheating the tool or altering critical dimensions through excessive etching.

The Risk of Insufficient Bias

Conversely, lowering the bias voltage to reduce heat risks compromising the adhesion.

If the ion energy is too low, the sputtering yield drops, and the oxide layer may not be fully removed. This results in "interfacial failure," where the coating peels off under stress because the fundamental bond was never established.

Making the Right Choice for Your Goal

Successful coating deposition depends on balancing aggressive cleaning with substrate preservation.

- If your primary focus is Maximum Adhesion: Ensure the process maintains the full 650V bias to guarantee the complete removal of oxide barriers for atomic-level bonding.

- If your primary focus is Dimensional Tolerance: Monitor the cleaning duration strictly, as the physical sputtering process removes a measurable (though microscopic) amount of substrate material.

High-bias ion cleaning is not merely a cleaning step; it is the bridge that mechanically locks the coating to the tool.

Summary Table:

| Feature | High-Bias Ion Cleaning (650V) | Standard Degreasing/Washing |

|---|---|---|

| Mechanism | Physical sputtering (Atomic bombardment) | Chemical/Mechanical surface wash |

| Target | Microscopic oxide films & impurities | Bulk oils, dust, and debris |

| Surface State | Chemically active metallic lattice | Visually clean but oxidized |

| Adhesion Level | Atomic-level bonding (Max strength) | Superficial/Interfacial bonding |

| Impact on Dimensions | Microscopic material removal | No change to substrate |

| Critical Goal | Eliminating interfacial failure | General surface preparation |

Maximize Coating Performance with KINTEK Precision

Don't let microscopic oxides compromise your tool's integrity. At KINTEK, we understand that superior coating starts with a pristine substrate. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific high-temperature and surface treatment needs. Whether you are aiming for maximum adhesion or strict dimensional tolerance, our specialized laboratory equipment provides the control you need to succeed.

Ready to elevate your material science? Contact our experts today to find the perfect high-temp furnace solution for your lab!

Visual Guide

References

- Sergey N. Grigoriev, Anna A. Okunkova. Increasing the Wear Resistance of Stamping Tools for Coordinate Punching of Sheet Steel Using CrAlSiN and DLC:Si Coatings. DOI: 10.3390/technologies13010030

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- What are the main differences between PVD and CVD coating techniques? Choose the Right Method for Your Application

- What is an example of chemical vapor deposition? Building the Microchips in Your Electronics

- What role does a Chemical Vapor Deposition (CVD) tube furnace system play in the preparation of monolayer graphene?

- Why is CVD suitable for dense, uniform films on irregular surfaces? Master Conformal Coating for Complex Shapes

- What is chemical vapor deposition (CVD) and its primary industrial application? Unlock Precision Thin Films for Electronics

- What environmental benefits does CVD offer? Achieve Sustainable Precision and Efficiency

- How does process complexity compare between PVD and CVD? Uncover Key Differences for Your Lab