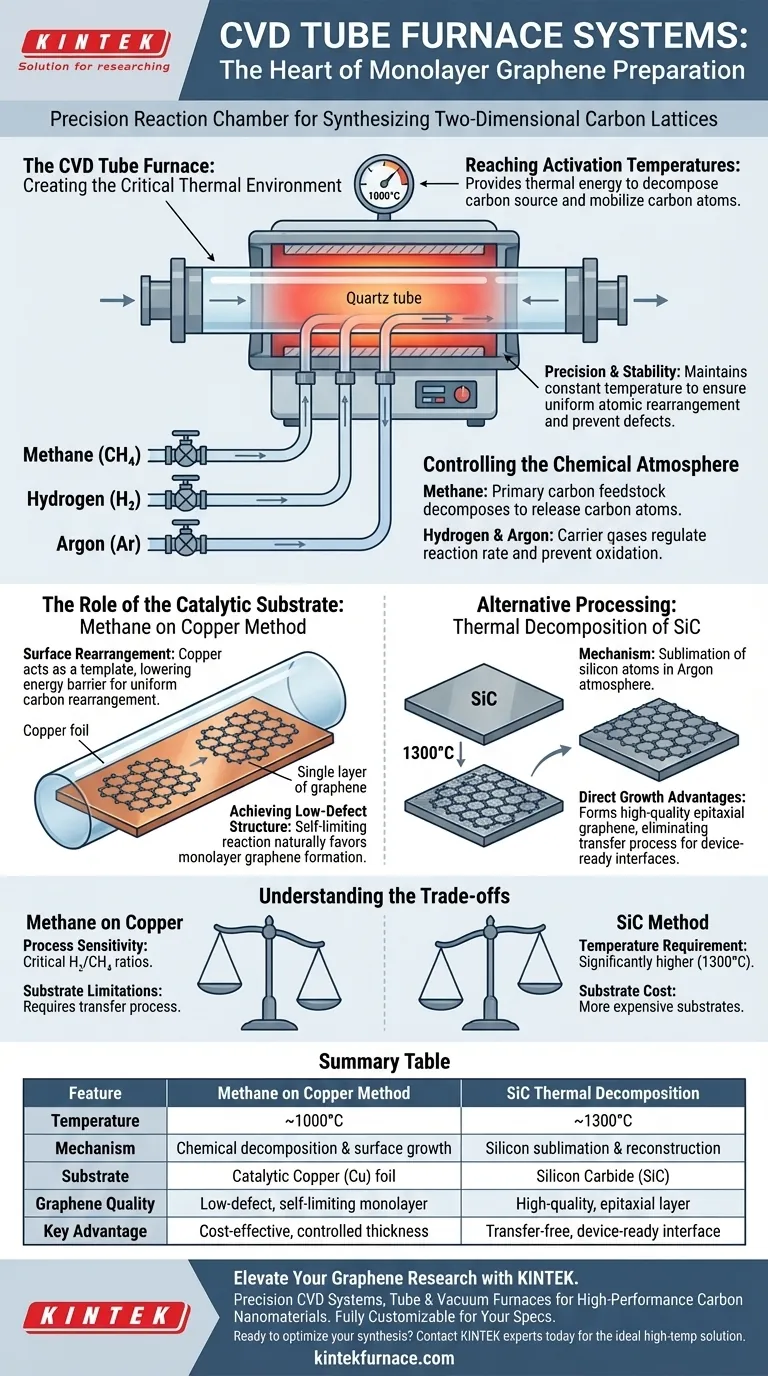

The Chemical Vapor Deposition (CVD) tube furnace acts as the precision reaction chamber required for synthesizing monolayer graphene. It creates a controlled high-temperature environment, typically reaching 1000°C, where carbon atoms can be chemically extracted from gas and systematically restructured into a two-dimensional lattice.

The system facilitates the growth of low-defect monolayer graphene by introducing methane over catalytic copper foil, utilizing precise thermal regulation and gas flow ratios to ensure uniform atomic rearrangement.

Creating the Critical Thermal Environment

Reaching Activation Temperatures

To initiate the growth process, the furnace must reach and maintain high temperatures, typically around 1000°C.

This intense heat provides the thermal energy required to decompose the carbon source and increase the mobility of carbon atoms on the substrate surface.

Precision and Stability

The defining feature of a high-quality CVD tube furnace is stability.

Fluctuations in temperature can interrupt the atomic rearrangement process, leading to defects or multi-layer patches rather than the desired monolayer structure.

Controlling the Chemical Atmosphere

The Carbon Source

The system introduces methane into the quartz reaction tube as the primary carbon feedstock.

Under the furnace's high heat, the methane decomposes, releasing carbon atoms necessary for building the graphene lattice.

The Carrier and Control Gases

Alongside methane, the system manages the flow of hydrogen and argon.

The furnace precisely controls the flow ratios of these gases to regulate the reaction rate and prevent the oxidation of the graphene or the substrate.

The Role of the Catalytic Substrate

Surface Rearrangement on Copper

In the standard method described, the process relies on a catalytic copper foil placed inside the reaction tube.

The copper acts as a template that lowers the energy barrier for the reaction, facilitating the uniform rearrangement of carbon atoms.

Achieving Low-Defect Structure

Because the copper has low carbon solubility, the reaction is self-limiting, which naturally favors the formation of a single atomic layer (monolayer).

The precise control of the furnace ensures that this rearrangement occurs smoothly, resulting in monolayer graphene with a low-defect structure.

Alternative Processing Capabilities

Thermal Decomposition of SiC

While standard synthesis uses copper and methane, industrial-grade CVD furnaces can also facilitate epitaxial graphene growth via Silicon Carbide (SiC) decomposition.

This process requires even higher temperatures (approximately 1300°C) in an argon atmosphere to control the sublimation of silicon atoms.

Direct Growth Advantages

In the SiC method, the remaining carbon atoms undergo surface reconstruction to form high-quality graphene directly on the substrate.

This creates a template for applications like gallium atom intercalation and eliminates the need to transfer the graphene to a new substrate later.

Understanding the Trade-offs

Process Sensitivity

The CVD process is highly sensitive to the ratios of hydrogen to methane.

Incorrect flow rates or unstable carrier gas control can lead to unchecked carbon deposition, resulting in unwanted multi-layer graphene or amorphous carbon soot.

Substrate Limitations

Using the standard copper foil method requires a post-growth transfer process to move the graphene onto a usable insulating surface.

While the SiC method described avoids this transfer, it requires significantly higher temperatures (1300°C vs 1000°C) and more expensive substrates.

Making the Right Choice for Your Goal

Whether you are conducting fundamental research or industrial fabrication, the furnace parameters dictate the material quality.

- If your primary focus is standard monolayer graphene: Utilize the methane-on-copper method at 1000°C for a self-limiting, low-defect growth process.

- If your primary focus is device-ready epitaxial graphene: Utilize the SiC thermal decomposition method at 1300°C to achieve a direct, transfer-free interface.

Success in graphene preparation ultimately depends on the furnace's ability to maintain thermodynamic equilibrium between the gas phase and the catalytic surface.

Summary Table:

| Feature | Methane on Copper Method | SiC Thermal Decomposition |

|---|---|---|

| Temperature | ~1000°C | ~1300°C |

| Mechanism | Chemical decomposition & surface growth | Silicon sublimation & reconstruction |

| Substrate | Catalytic Copper (Cu) foil | Silicon Carbide (SiC) |

| Graphene Quality | Low-defect, self-limiting monolayer | High-quality, epitaxial layer |

| Key Advantage | Cost-effective, controlled thickness | Transfer-free, device-ready interface |

Elevate Your Graphene Research with KINTEK

Precision is the difference between a perfect monolayer and a defective sample. KINTEK provides industry-leading CVD systems, Tube, and Vacuum furnaces engineered to deliver the thermal stability and gas flow accuracy required for high-performance carbon nanomaterials.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique laboratory or industrial specs—whether you are working with copper foil or SiC decomposition.

Ready to optimize your synthesis? Contact KINTEK experts today to find the ideal high-temp solution for your needs.

Visual Guide

References

- Arash Vaghef‐Koodehi. Ultrasensitive Graphene-TMD Heterostructure Optical Biosensors Integrated with Silicon Photonics for Label-Free Detection. DOI: 10.21203/rs.3.rs-7279468/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the primary role of heating filaments within an iCVD process? Enabling Low-Temperature Polymerization

- What is the primary function of CVT equipment in growth of CrSb crystals? High-Purity Single Crystal Growth

- What are the advantages of using a high-purity quartz tube in CVD? Unlock Superior Film Growth and Purity

- What are intermetallic compounds, and how are they used in CVD? Unlock Advanced Thin Film Solutions

- What is the temperature range for CVD furnaces? From 700°C to 1950°C for Precise Material Synthesis

- Why must the deposition of an additional a-Si protective layer over a barrier layer be completed without breaking vacuum?

- How does the scalability of CVD furnaces benefit different production needs? Achieve Seamless Lab-to-Production Transition

- How do IoT gas sensors and Autoencoders contribute to CVD furnace safety? Enhance Pipeline Integrity and Monitoring