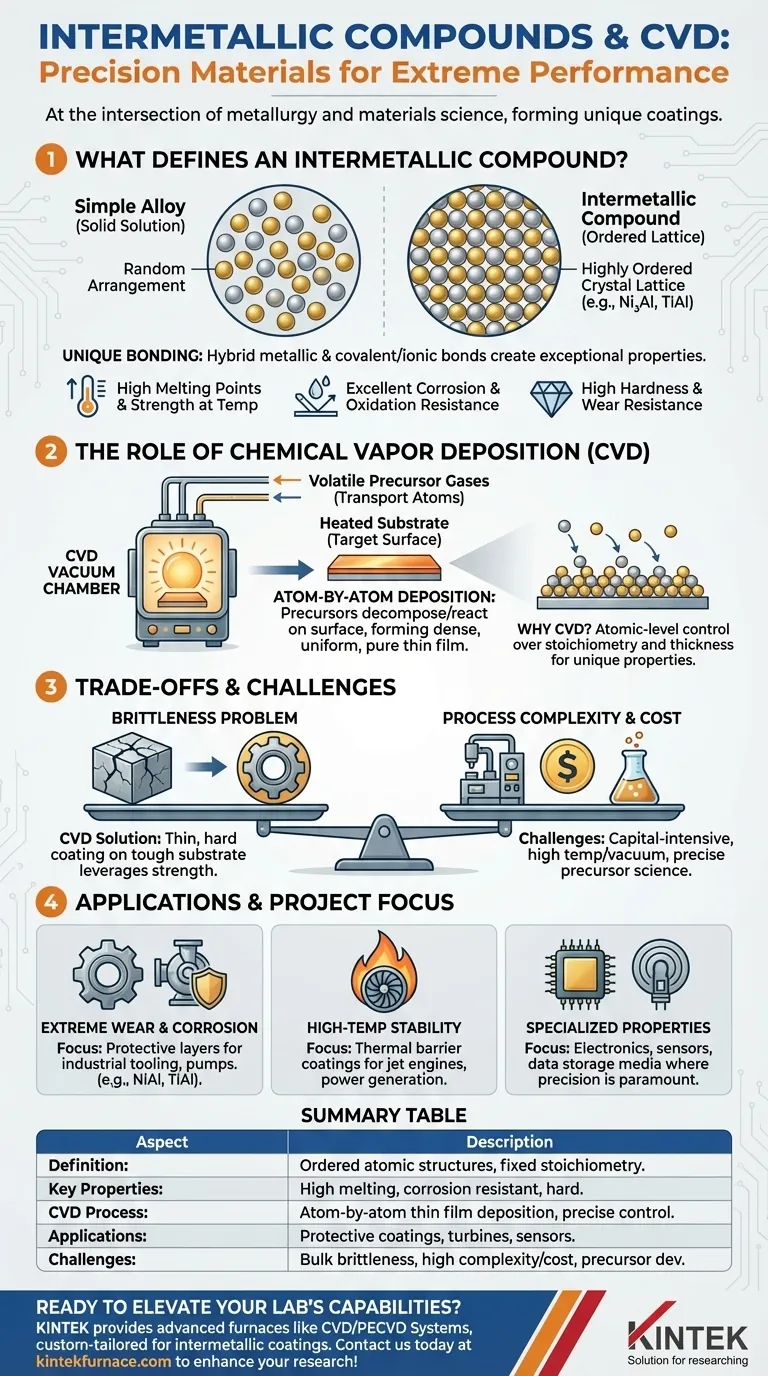

At the intersection of metallurgy and materials science, intermetallic compounds represent a unique class of materials formed from a precise, ordered atomic arrangement of two or more metallic elements. Chemical Vapor Deposition (CVD) is a sophisticated manufacturing process used to apply these compounds as high-performance thin films, creating surfaces with properties that far exceed those of the individual metals.

The true power of this combination lies in using the atomic-level precision of CVD to create intermetallic coatings with exceptional hardness, high-temperature strength, and corrosion resistance—properties often impossible to achieve with conventional bulk alloys.

What Defines an Intermetallic Compound?

Intermetallic compounds are not simply mixtures of metals. Their distinct, ordered structure is the source of their highly desirable, and sometimes challenging, properties.

Beyond Simple Alloys

Unlike a typical alloy, which is a solid solution with a random arrangement of atoms, an intermetallic compound has a highly ordered crystal lattice. Atoms of the different metals occupy specific, predictable sites within the crystal structure, often in fixed stoichiometric ratios (e.g., Ni₃Al or TiAl).

A Unique Bonding Structure

The bonding within intermetallics is a hybrid, exhibiting characteristics of both metallic and covalent/ionic bonds. This unique nature is what gives them properties of both metals (like thermal conductivity) and ceramics (like high hardness and brittleness).

Key Properties of Interest

The ordered structure of intermetallics results in a powerful combination of physical properties, including:

- High melting points and strength at elevated temperatures.

- Excellent corrosion and oxidation resistance.

- High hardness and wear resistance.

The Role of Chemical Vapor Deposition (CVD)

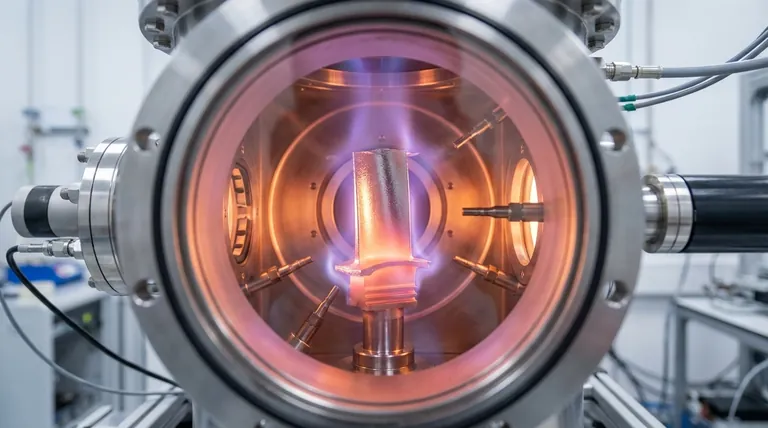

CVD is not just a coating method; it's a precise, bottom-up fabrication technique perfectly suited for creating high-purity intermetallic films.

Understanding the CVD Process

CVD is a process performed in a vacuum chamber where volatile precursor gases, containing the required metallic elements, are introduced. These gases are not the final material itself but are designed to transport the atoms to the target surface.

Atom-by-Atom Deposition

The substrate (the part to be coated) is heated, causing the precursor gases to decompose or react on its surface. This deposits the desired material atom-by-atom or molecule-by-molecule, forming a dense, uniform, and highly pure thin film. The process requires no subsequent curing.

Why Use CVD for Intermetallics?

CVD offers the atomic-level control needed to form the precise, ordered crystal structure of an intermetallic. By carefully managing gas flow rates, temperature, and pressure, engineers can precisely dictate the film’s chemical composition (stoichiometry) and thickness, which is critical for achieving its unique properties.

Understanding the Trade-offs and Challenges

While powerful, the combination of intermetallics and CVD is reserved for demanding applications due to several inherent complexities.

The Brittleness Problem

Many intermetallic compounds are notoriously brittle in their bulk form, which limits their use as structural components. However, when applied as a thin, hard coating via CVD, the toughness of the underlying substrate compensates for this brittleness, leveraging the intermetallic's strengths without its primary weakness.

Process Complexity and Cost

CVD is a sophisticated, capital-intensive process. It requires vacuum systems, high temperatures, and careful handling of precursor gases, making it more expensive than traditional plating or thermal spray methods.

Precursor Material Science

Developing and selecting the correct precursor gases is a significant challenge. The chemicals must be volatile enough to be transported as a gas but stable enough not to decompose prematurely, all while reacting predictably on the substrate to form the exact intermetallic compound desired.

How to Apply This to Your Project

Deciding to use a CVD intermetallic coating depends entirely on whether the performance demands of your component justify the complexity and cost.

- If your primary focus is extreme wear and corrosion resistance: Consider intermetallic coatings like nickel aluminide (NiAl) or titanium aluminide (TiAl) for protective layers on industrial tooling, pump components, or chemical processing equipment.

- If your primary focus is high-temperature stability: CVD-deposited intermetallics are an excellent choice for thermal barrier coatings on turbine blades in jet engines and power generation systems, where they protect the base metal from extreme heat.

- If your primary focus is specialized electronic or magnetic properties: Certain intermetallic thin films created via CVD are essential for manufacturing advanced sensors, data storage media, and semiconductor components where precision is paramount.

By combining the unique material properties of intermetallics with the manufacturing precision of CVD, engineers can develop advanced surface solutions that solve problems conventional materials cannot.

Summary Table:

| Aspect | Description |

|---|---|

| Definition | Ordered atomic structures of two or more metals with fixed stoichiometry (e.g., Ni₃Al). |

| Key Properties | High melting points, strength at high temperatures, corrosion/oxidation resistance, hardness, and wear resistance. |

| CVD Process | Uses precursor gases to deposit atom-by-atom, forming pure, uniform thin films with precise control. |

| Applications | Protective coatings for tooling, turbine blades, sensors, and semiconductors in demanding environments. |

| Challenges | Brittleness in bulk form, high process complexity, cost, and precursor development requirements. |

Ready to elevate your lab's capabilities with custom high-temperature furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures they precisely meet your unique experimental needs for intermetallic coatings and beyond. Contact us today to discuss how we can enhance your research and production efficiency!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What are the advantages of PECVD? Enable Low-Temp, High-Quality Film Deposition

- Is PECVD directional? Understanding Its Non-Line-of-Sight Advantage for Complex Coatings

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings