Maintaining a continuous vacuum is non-negotiable because breaking it exposes the sensitive Titanium-based barrier layer to the atmosphere. This exposure causes immediate, uncontrolled oxidation on the surface of the barrier layer, which severely compromises the cleanliness and chemical stability of the interface before the amorphous silicon (a-Si) protective layer can be applied.

By keeping the system under vacuum, you prevent oxygen from contaminating the barrier layer. This "in-situ" process guarantees a pristine interface, which is required for the barrier to effectively resist erosion from aluminum paste.

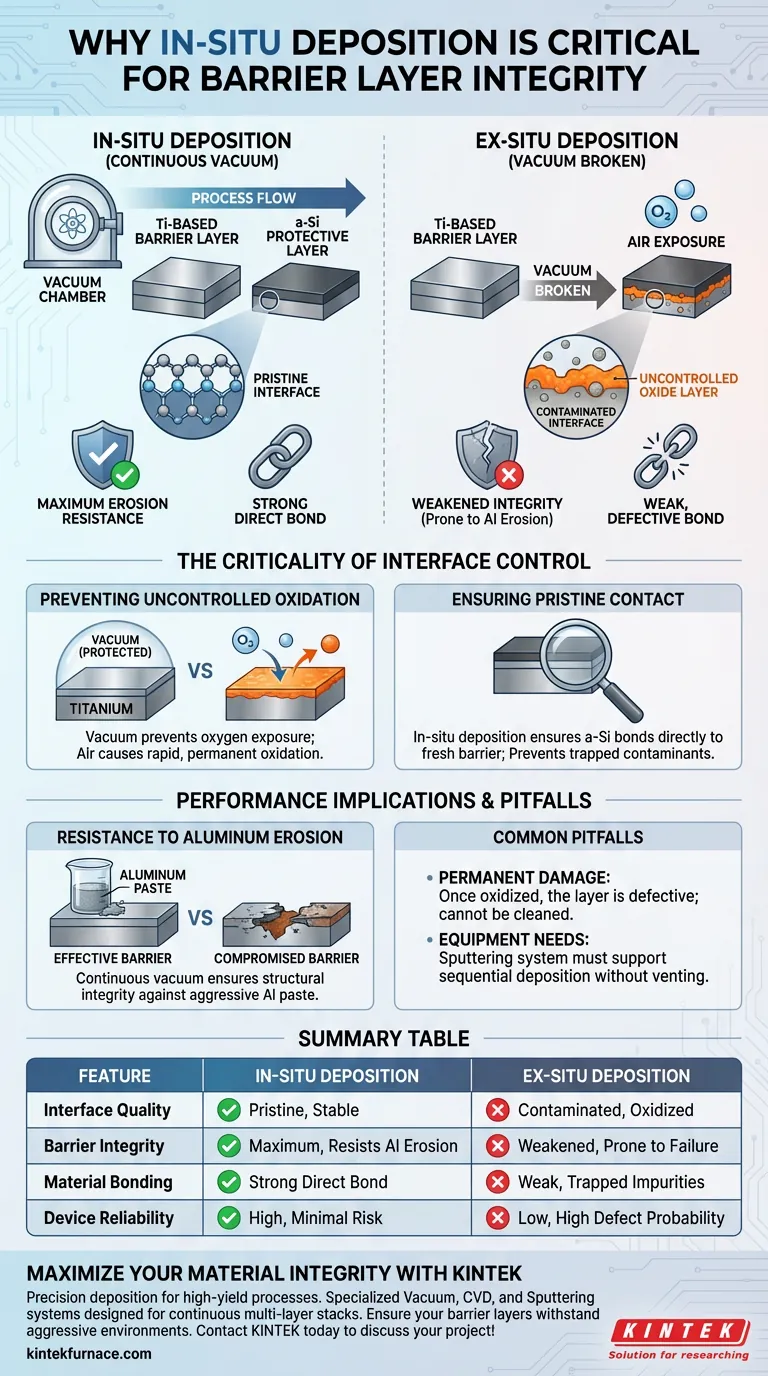

The Criticality of Interface Control

To understand why the vacuum cannot be broken, one must look beyond the deposition itself and examine the chemical sensitivity of the materials involved.

Preventing Uncontrolled Oxidation

Titanium-based barrier layers are highly reactive to oxygen.

If the vacuum is broken, the barrier layer is instantly exposed to air. This results in the rapid formation of an oxide layer on the barrier's surface. This oxidation is uncontrolled and creates a chemical impurity that degrades the material's properties.

Ensuring Pristine Contact

The connection between the barrier layer and the subsequent a-Si layer determines the stack's integrity.

Depositing the a-Si layer in-situ (without breaking vacuum) ensures that the a-Si bonds directly to the fresh barrier material. This prevents contaminants or oxide layers from becoming trapped between the two functional layers.

Performance Implications for the Device

The method of deposition directly dictates the mechanical and chemical resilience of the final component.

Resistance to Aluminum Erosion

The primary function of the barrier layer is to stop aluminum (Al) paste from eroding the underlying materials.

If the interface is compromised by oxidation due to a vacuum break, the barrier's ability to resist this erosion is weakened. A continuous vacuum ensures the barrier retains the structural integrity needed to withstand the aggressive nature of Al paste.

Interface Cleanliness

A clean interface is the foundation of device reliability.

Any impurities introduced by air exposure can create weak points. These weak points can lead to delamination or failure under stress, rendering the protective stack ineffective.

Common Pitfalls to Avoid

While maintaining a vacuum adds constraints to the manufacturing process, the alternative introduces unacceptable risks.

The Risk of Process Interruption

It is a misconception that a barrier layer can be "cleaned" after air exposure.

Once a Ti-based layer oxidizes, the damage is effectively permanent regarding interface quality. Attempting to resume deposition after a vacuum break will result in a defective multi-layer stack.

Equipment Configuration

This requirement necessitates specific equipment capabilities.

The sputtering system must be capable of sequential deposition. If the equipment requires venting between steps, it is unsuitable for creating high-reliability barrier stacks of this composition.

Making the Right Choice for Your Process

To ensure the durability and effectiveness of your barrier layers, apply the following principles:

- If your primary focus is erosion resistance: Ensure your sputtering process is fully in-situ to prevent the formation of weak oxide layers that fail against Al paste.

- If your primary focus is process yield: eliminate any steps that require venting the chamber between the barrier and protective layer depositions to minimize defect rates.

Control the vacuum, and you control the integrity of the entire protective stack.

Summary Table:

| Feature | In-Situ Deposition (No Vacuum Break) | Ex-Situ Deposition (Vacuum Broken) |

|---|---|---|

| Interface Quality | Pristine and chemically stable | Contaminated with uncontrolled oxides |

| Barrier Integrity | Maximum; resists Al paste erosion | Weakened; prone to chemical failure |

| Material Bonding | Strong direct bond (a-Si to Barrier) | Weak bond trapped between impurities |

| Device Reliability | High; minimal risk of delamination | Low; high probability of defect formation |

Maximize Your Material Integrity with KINTEK

Precision in deposition is the difference between a high-yield process and costly material failure. Backed by expert R&D and manufacturing, KINTEK offers specialized Vacuum, CVD, and Sputtering systems designed to maintain continuous vacuum for critical multi-layer stacks. Whether you need Muffle, Tube, or custom high-temp furnaces, our equipment is engineered to ensure your barrier layers withstand the most aggressive environments.

Ensure your lab's success with equipment tailored to your unique needs. Contact us today to discuss your project!

Visual Guide

References

- TiN <sub> <i>x</i> </sub> and TiO <sub> <i>x</i> </sub> /TiN <sub> <i>x</i> </sub> Barrier Layers for Al‐Based Metallization of Passivating Contacts in Si Solar Cells. DOI: 10.1002/pssr.202500168

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How do quartz tube dimensions influence MoS2 CVD synthesis? Optimize Flow for High-Quality Monolayers

- What is Chemical Vapor Infiltration (CVI)? Build Dense, High-Performance Composites

- What are the typical process temperature ranges for HT CVD and MT CVD processes? Optimize Your Coating Performance

- What advantages do CVD coatings provide for sub-micron filters? Enhance Purity and Durability in Filtration

- What are the applications of CVD in producing single-crystal metal oxides and net-shape products? Unlock Precision Manufacturing

- What challenges are associated with CVD? Overcome Cost, Control, and Safety Hurdles

- How does high vacuum thermal evaporation equipment contribute to Cu2SnS3 (CTS) PVD? High-Purity Film Solutions

- What is the purpose of using a mechanical vacuum pump for CVD MoS2 preparation? Ensure High-Purity Material Synthesis