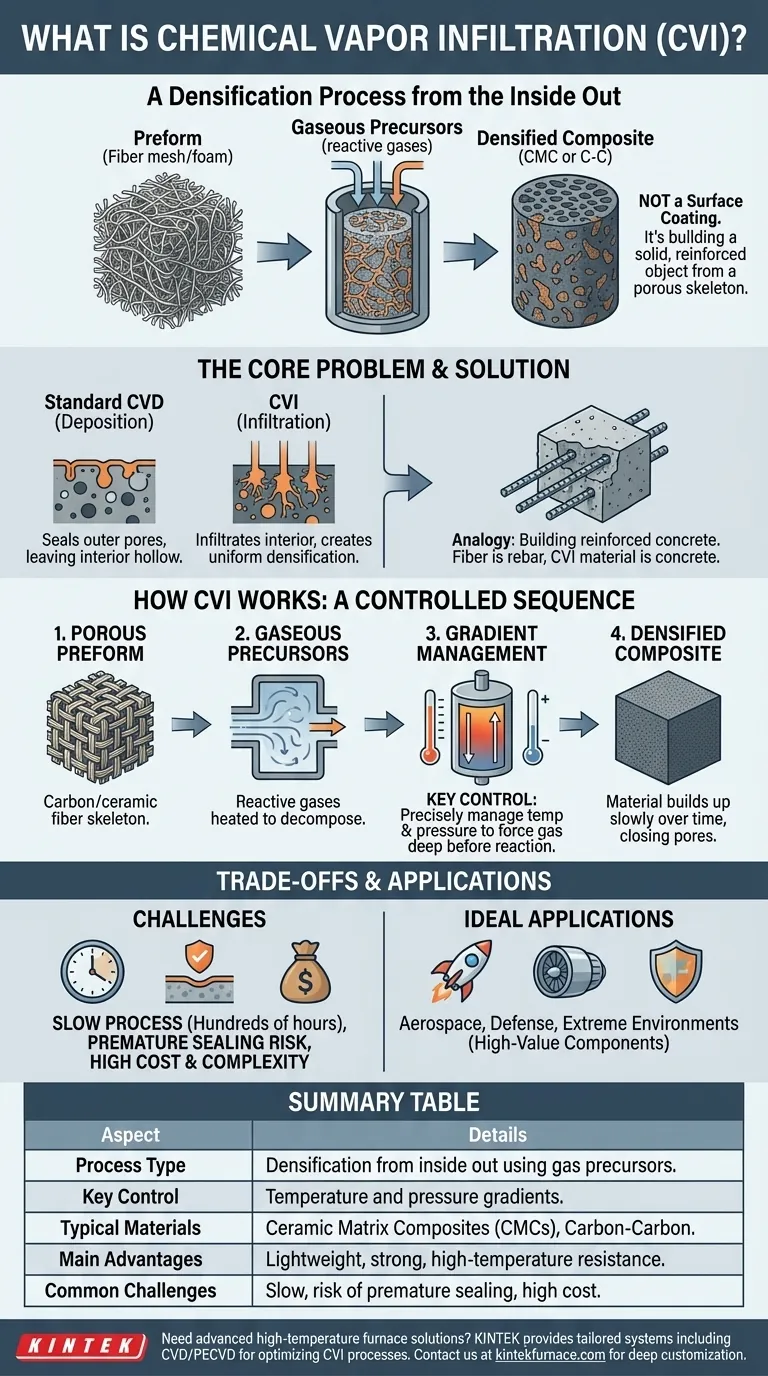

At its core, Chemical Vapor Infiltration (CVI) is a manufacturing process used to build a dense, solid composite material from the inside out. Unlike coating a surface, CVI works by taking a porous structure, like a fiber mesh or foam, and systematically filling all its internal voids with a new material deposited from a gas, creating a solid, reinforced object.

The critical distinction to understand is that Chemical Vapor Infiltration is not about surface coating. It is a densification process designed to transform a porous, fibrous "skeleton" into a solid, high-performance composite material.

The Core Problem CVI Solves: Building from Within

Standard manufacturing techniques often struggle to create materials that are simultaneously lightweight, strong, and highly resistant to extreme temperatures. CVI was developed specifically to produce these advanced composite materials.

The Limitation of Standard Deposition

Chemical Vapor Deposition (CVD), the parent process of CVI, excels at applying thin, protective coatings to the outer surface of a solid object. If you tried to use standard CVD on a porous structure, it would quickly seal the outer pores, leaving the interior hollow and weak.

CVI's Solution: Infiltrating the Interior

CVI modifies the CVD process to overcome this limitation. The goal is to encourage the chemical reaction and material deposition to occur deep within the porous structure, not just at the surface. This ensures the entire component is uniformly filled, or "densified."

Think of it like building reinforced concrete. The porous fiber structure is the rebar, and the material deposited by CVI is the concrete that fills all the gaps and binds everything into a single, incredibly strong part.

How Chemical Vapor Infiltration Works

The CVI process is a slow, carefully controlled sequence designed to ensure uniform infiltration. It relies on managing temperature and pressure to guide the chemical reactions to the right place.

The Starting Point: A Porous Preform

The process begins with a "preform," which is the porous skeleton of the final part. This can be made from woven carbon or ceramic fibers, felts, or even foams, shaped into the desired final geometry.

The Process: Gaseous Precursors

This preform is placed inside a reactor, which is then filled with a specific mixture of reactive gases, known as precursors. When these gases are heated, they decompose and deposit a solid material.

The Key Control: Gradient Management

This is the most critical aspect of CVI. By precisely controlling temperature and pressure gradients within the reactor, engineers can force the gas to permeate deep into the preform before it reacts. The reaction rate is deliberately kept slow to allow uniform deposition throughout the preform's thickness.

The Result: A Densified Composite

Over many hours or even weeks, the deposited material gradually builds up on the fibers inside the preform, closing the pores and increasing the component's density. The final product is a Ceramic Matrix Composite (CMC) or Carbon-Carbon (C-C) composite—a solid part where the original fiber skeleton is now embedded in a new ceramic or carbon matrix.

Understanding the Trade-offs

While powerful, CVI is a specialized process with significant challenges that limit its use to high-value applications.

The Slow Pace of Infiltration

The need for slow, controlled deposition means CVI is an extremely time-consuming process. A single component can take hundreds or even thousands of hours to fully densify, making it unsuitable for mass production.

The Risk of Premature Sealing

If the process parameters are not perfectly controlled, the outer surface can seal off before the interior is fully dense. This traps voids inside the component, creating a critical flaw that compromises its structural integrity.

High Cost and Complexity

The combination of complex reactor equipment, long processing times, and high energy consumption makes CVI an expensive manufacturing method. Its use is justified only when the performance requirements—like extreme heat resistance—are paramount.

Making the Right Choice for Your Goal

Selecting between CVI and related processes depends entirely on the final component's intended function.

- If your primary focus is creating a strong, heat-resistant, and lightweight bulk component: CVI is the correct process for infiltrating a fiber preform to produce a Ceramic or Carbon-Carbon composite part.

- If your primary focus is applying a thin, protective coating to an existing solid object: Standard Chemical Vapor Deposition (CVD) is the more efficient and appropriate choice.

Ultimately, Chemical Vapor Infiltration empowers engineers to create materials that can survive in some of the most demanding environments imaginable.

Summary Table:

| Aspect | Details |

|---|---|

| Process Type | Densification from inside out using gas precursors |

| Key Control Parameters | Temperature and pressure gradients |

| Typical Materials Produced | Ceramic Matrix Composites (CMCs), Carbon-Carbon composites |

| Main Advantages | Lightweight, strong, high-temperature resistance |

| Common Challenges | Slow process, risk of premature sealing, high cost |

| Ideal Applications | High-value components for aerospace, defense, and extreme environments |

Need advanced high-temperature furnace solutions for your composite manufacturing? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, such as optimizing CVI processes for superior material performance. Contact us today to discuss how our solutions can enhance your research and production efficiency!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- What are the operational benefits of using a CVD Tube Furnace? Enhance Precision and Efficiency in Your Lab

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials