The physical dimensions of the quartz tube fundamentally dictate the gas flow dynamics within a CVD system. Specifically, the tube’s diameter and length regulate the stability of laminar flow and the uniformity of precursor distribution. These specifications turn the tube from a passive vessel into an active component that directly influences the quality and consistency of molybdenum disulfide (MoS2) growth.

The geometry of the reaction chamber is the primary driver of flow stability. A sufficiently wide and long tube establishes a predictable velocity field, minimizing turbulence and ensuring uniform deposition across substrates.

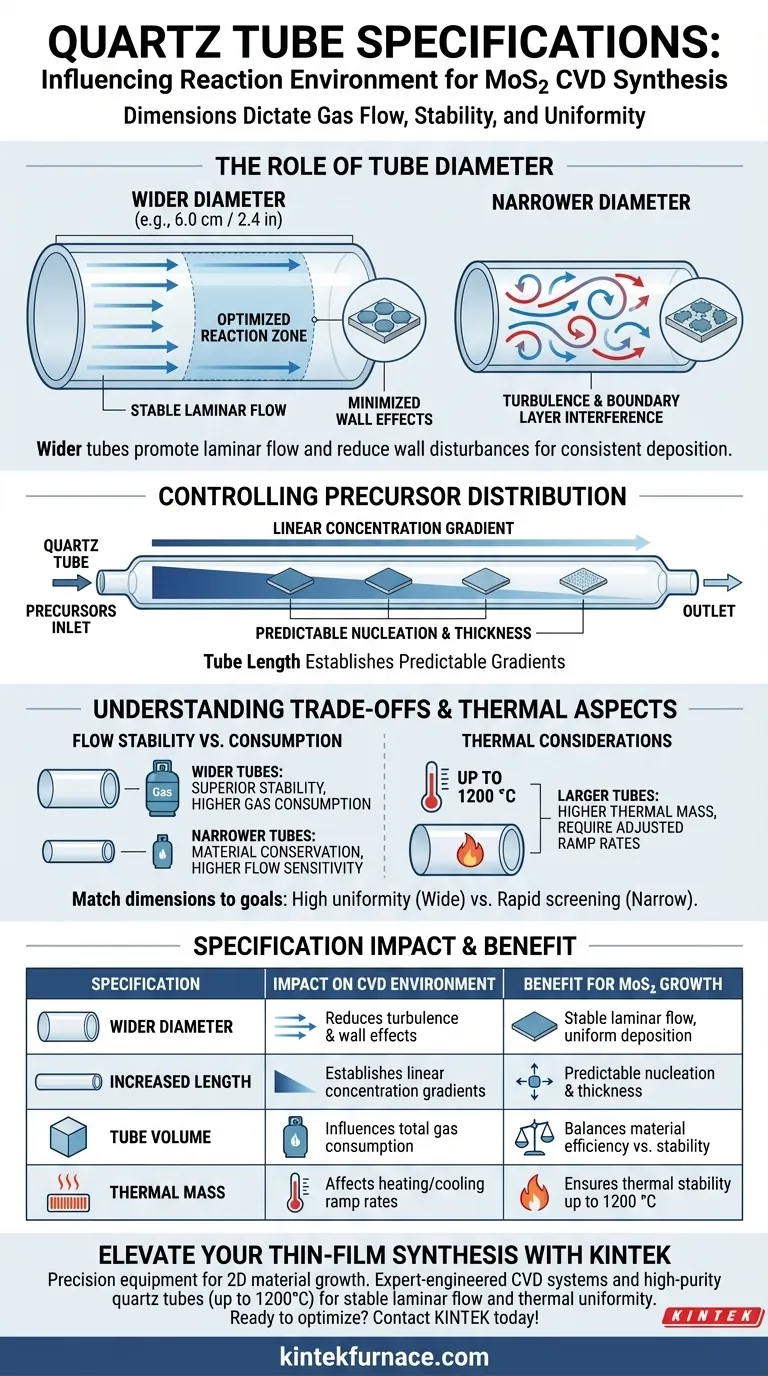

The Role of Tube Diameter in Gas Flow

Establishing Laminar Flow

To achieve high-quality MoS2 synthesis, the reaction environment must maintain a stable laminar flow. A tube with a sufficiently wide diameter—such as the 6.0 cm (approx. 2.4 inches) specification noted in successful setups—is critical for establishing this flow regime. Narrower tubes increase the likelihood of turbulence, which can lead to unpredictable deposition rates.

Minimizing Wall Effects

Gas flowing through a tube experiences friction and drag against the inner walls. In a wider tube, the central reaction zone is physically distanced from these boundary layer disturbances. This separation ensures that the substrates interact with a consistent gas stream rather than the chaotic flow found near the tube walls.

Controlling Precursor Distribution

Predictable Concentration Gradients

The physical volume defined by the tube allows for the development of predictable precursor concentration gradients. As the gas travels down the length of a tube (e.g., 60.0 cm), the concentration of reactants changes in a linear, calculable fashion. This predictability allows researchers to position substrates precisely to achieve specific nucleation densities or layer thicknesses.

Uniformity Across Orientations

A stable velocity field, enabled by correct tube dimensions, ensures that the precursor supply is uniform regardless of how the substrate is angled. This is essential for achieving uniform MoS2 growth across substrates positioned in various orientations, preventing "shadowing" effects where gas flow is blocked or uneven.

Understanding the Trade-offs

Impact on Gas Consumption

While larger tubes (e.g., 2-inch or 6.0 cm diameters) offer superior flow stability, they increase the total volume of the reaction chamber. This generally requires higher flow rates or larger quantities of precursors to maintain the necessary partial pressures compared to smaller, 1-inch setups.

Thermal Considerations

Standard CVD systems for this application are designed to operate with quartz tubes at temperatures up to 1200 °C. However, the physical size of the tube influences the thermal mass. Larger tubes may require adjusted ramp rates to ensure the internal temperature stabilizes uniformly without shocking the quartz material.

Making the Right Choice for Your Goal

When selecting a quartz tube for your CVD system, align the dimensions with your specific research objectives.

- If your primary focus is high uniformity and large-area growth: Prioritize a wider tube diameter (approx. 6.0 cm or 2 inches) to maximize the laminar flow region and reduce wall interference.

- If your primary focus is rapid screening or material conservation: Consider a narrower tube (1 inch), accepting slightly higher flow sensitivity in exchange for reduced precursor consumption.

By matching the tube's physical specifications to your fluid dynamic requirements, you convert a variable into a constant, ensuring reproducible synthesis results.

Summary Table:

| Specification | Impact on CVD Environment | Resulting Benefit for MoS2 Growth |

|---|---|---|

| Wider Diameter | Reduces turbulence & wall effects | Stable laminar flow and uniform deposition |

| Increased Length | Establishes linear concentration gradients | Predictable nucleation density and thickness |

| Tube Volume | Influences total gas consumption | Balances material efficiency vs. flow stability |

| Thermal Mass | Affects heating/cooling ramp rates | Ensures thermal stability up to 1200 °C |

Elevate Your Thin-Film Synthesis with KINTEK

Precision in 2D material growth starts with the right equipment. KINTEK provides expert-engineered CVD systems, Muffle, Tube, Rotary, and Vacuum furnaces designed to meet the rigorous demands of MoS2 synthesis. Our high-purity quartz tubes and customizable high-temperature systems (up to 1200°C and beyond) ensure you achieve the stable laminar flow and thermal uniformity essential for large-area, high-quality deposition.

Ready to optimize your lab's CVD performance? Contact our technical specialists today to discuss our customizable furnace solutions and how we can support your unique research needs.

Visual Guide

References

- Feng Liao, Zewen Zuo. Optimizing the Morphology and Optical Properties of MoS2 Using Different Substrate Placement: Numerical Simulation and Experimental Verification. DOI: 10.3390/cryst15010059

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the advantages of using a CVD system? Achieve Precision and Uniformity for Complex Thin Films

- How does the CVD process begin? Master Precise Film Deposition from the Start

- What factors influence the quality of CVD coatings? Master Key Parameters for Superior Film Performance

- Why is ultrasonic cleaning of Si/SiO2 substrates required before MoS2 growth? Ensure High-Quality CVD Results

- How does a recirculating chiller influence the quality of polymer films in iCVD? Achieve Superior Surface Smoothness

- What is the role of a horizontal oxidation furnace? Enhancing Silicon Micro-Tip Diffusion Barriers

- What are the industrial applications of materials deposited by CVD? Unlock High-Performance Thin Films for Your Industry

- What types of diamond and carbon nanofilms can be prepared using CVD? Explore the Full Spectrum from Diamond to Graphene