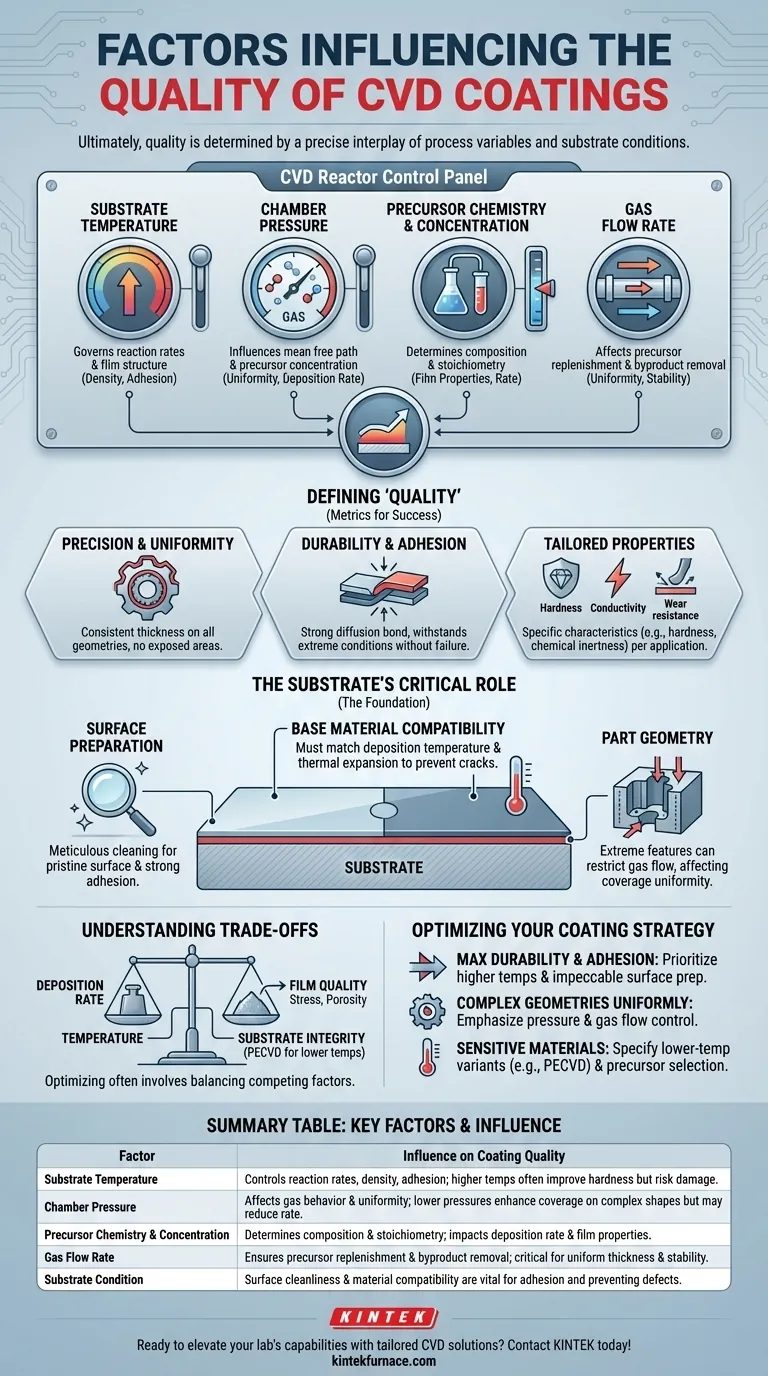

Ultimately, the quality of a Chemical Vapor Deposition (CVD) coating is determined by a precise interplay of process variables and substrate conditions. The most critical factors are the substrate temperature, chamber pressure, the chemistry and concentration of precursor gases, and the gas flow rates. Mastering these elements allows for the deliberate engineering of a coating's final properties, from its thickness and uniformity to its chemical composition and microstructure.

The core principle to understand is that CVD is not a single process, but a highly tunable system. Achieving a high-quality coating is a result of intentionally balancing the deposition process parameters with the physical and chemical nature of the substrate being coated.

Defining 'Quality' in a CVD Coating

Before adjusting process variables, it's essential to define what "quality" means for your application. The advantages of a well-executed CVD process become the metrics by which we measure its success.

Precision and Uniformity

A high-quality coating is exceptionally uniform across the entire surface of a part. It maintains a consistent thickness even on complex geometries, including internal features and fine details, ensuring there are no exposed areas that could become points of failure.

Durability and Adhesion

Quality is often measured by performance under stress. A superior coating forms a strong, diffusion-bonded layer with the substrate, providing exceptional adhesion. This allows it to withstand extreme temperatures, rapid thermal cycling, and high mechanical loads without delaminating or failing.

Tailored Chemical and Physical Properties

The CVD process allows for the creation of films with highly specific characteristics. Quality can mean achieving a target level of hardness, chemical inertness, electrical conductivity, or wear resistance, depending on the application's unique demands.

Core Process Parameters: The Levers of Control

These are the primary variables within the CVD reactor that are adjusted to manipulate the coating's formation and final characteristics.

Substrate Temperature

Temperature is arguably the most critical parameter. It directly governs the reaction rates on the substrate surface. Higher temperatures generally increase the deposition rate and can lead to denser, more crystalline film structures, which often improves adhesion and hardness.

Chamber Pressure

The pressure inside the reactor influences the mean free path of gas molecules and the concentration of precursors near the substrate. Lower pressures can improve coating uniformity on complex shapes but may decrease the deposition rate.

Precursor Chemistry and Concentration

The choice of precursor gases fundamentally determines the coating's composition (e.g., silicon nitride, titanium carbide). The concentration of these gases, along with the ratio between them, directly impacts the deposition rate and the stoichiometry of the resulting film.

Gas Flow Rate

The rate at which gases flow through the chamber affects the replenishment of precursors at the substrate surface and the removal of reaction byproducts. Proper flow is essential for maintaining process stability and achieving uniform thickness across all parts in a batch.

The Substrate's Critical Role

The part being coated is not a passive participant. Its condition and design are as crucial as the process parameters themselves.

Surface Preparation

A coating can only be as good as the surface it is applied to. The substrate must be meticulously cleaned to remove any oils, oxides, or other contaminants. A pristine surface is non-negotiable for achieving strong adhesion.

Base Material Compatibility

The substrate material must be compatible with the deposition temperature and chemistry. Mismatches in thermal expansion coefficients between the coating and the substrate can create stress during cooling, potentially leading to cracks or delamination.

Part Geometry

While CVD is excellent for coating complex shapes, extreme features can still pose a challenge. Very deep, narrow blind holes or sharp internal corners can create regions where gas flow is restricted, potentially leading to thinner or non-uniform coverage. Optimizing part design can mitigate these effects.

Understanding the Trade-offs

Optimizing the CVD process almost always involves balancing competing factors. Understanding these trade-offs is key to achieving a successful outcome.

The most common trade-off is between deposition rate and film quality. Pushing for a faster coating process by increasing temperature or precursor concentration can sometimes introduce stress, create a more porous microstructure, or reduce uniformity.

Another critical balance is temperature vs. substrate integrity. The high temperatures required for many conventional CVD processes can damage sensitive substrate materials. This limitation has led to the development of lower-temperature methods like Plasma-Enhanced CVD (PECVD), which use energy from plasma to drive reactions instead of purely thermal energy.

Finally, optimizing for one property may compromise another. For example, a coating designed for extreme hardness might be more brittle than a coating optimized for ductility and load-bearing capacity.

Optimizing Your Coating Strategy

Your ideal process parameters depend entirely on your primary goal. Use these principles as a starting point for discussions with your coating provider.

- If your primary focus is maximum durability and adhesion: Prioritize higher process temperatures (within the substrate's limits) and an impeccable surface preparation protocol.

- If your primary focus is coating complex geometries uniformly: Emphasize control over chamber pressure and gas flow dynamics to ensure precursors reach all surfaces evenly.

- If your primary focus is coating temperature-sensitive materials: You must specify the use of a lower-temperature CVD variant and work closely on precursor selection to achieve the desired reaction at a safe temperature.

By deliberately controlling both the process and the part, you can engineer a CVD coating that delivers precisely the performance your application demands.

Summary Table:

| Factor | Influence on Coating Quality |

|---|---|

| Substrate Temperature | Controls reaction rates, film density, and adhesion; higher temps often improve hardness but risk substrate damage. |

| Chamber Pressure | Affects gas molecule behavior and uniformity; lower pressures enhance coverage on complex shapes but may reduce deposition rate. |

| Precursor Chemistry & Concentration | Determines coating composition and stoichiometry; impacts deposition rate and film properties like hardness or conductivity. |

| Gas Flow Rate | Ensures precursor replenishment and byproduct removal; critical for uniform thickness and process stability. |

| Substrate Condition | Surface cleanliness and material compatibility are vital for strong adhesion and preventing defects like delamination. |

Ready to elevate your lab's capabilities with tailored CVD solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Our deep customization ensures precise alignment with your unique experimental needs, enhancing coating quality, durability, and efficiency. Don't settle for standard—contact us today to discuss how our expertise can optimize your CVD processes and drive your research forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition