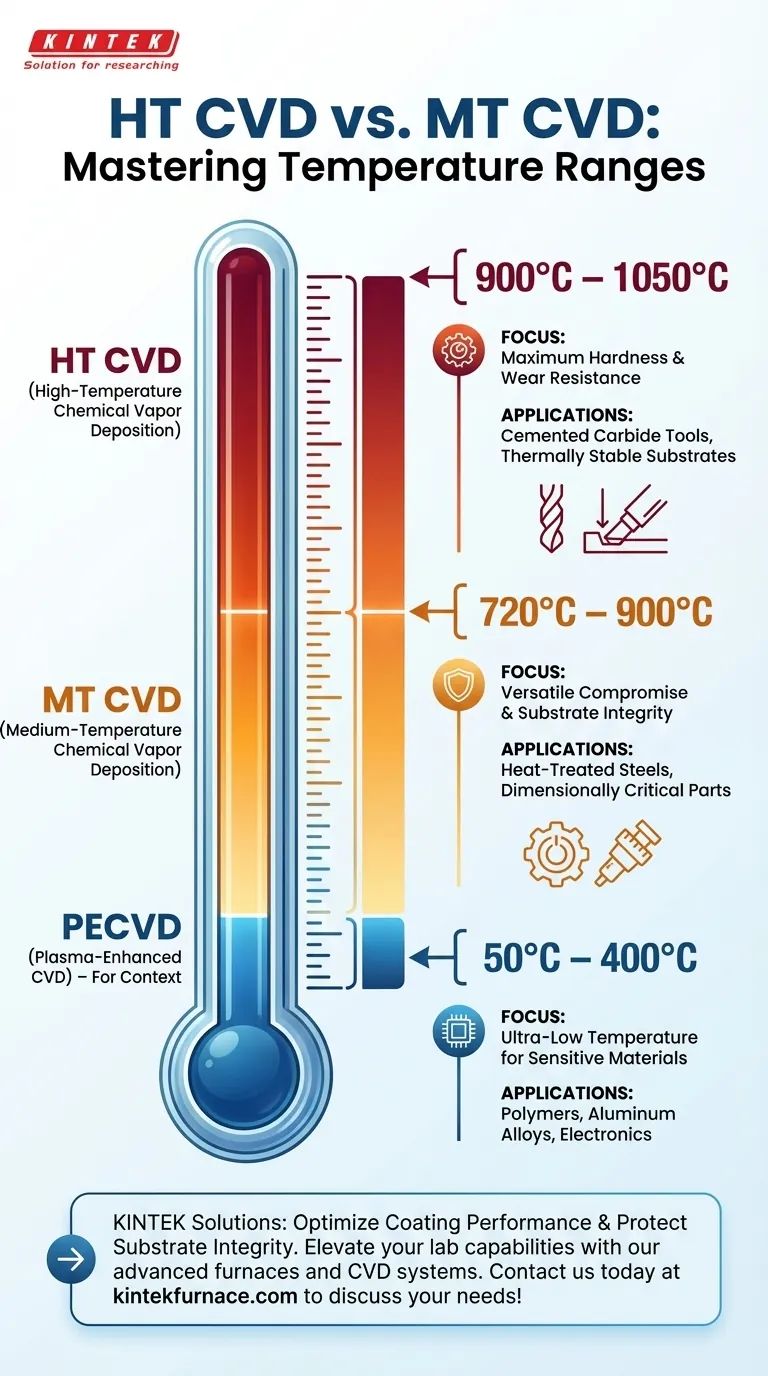

In short, High-Temperature Chemical Vapor Deposition (HT CVD) operates between 900°C and 1050°C, while Medium-Temperature (MT CVD) processes run at a lower range of 720°C to 900°C. This temperature difference is the single most important factor in determining which process is suitable for a given application, as it dictates the trade-off between ultimate coating performance and the thermal stability of the part being coated.

The choice between HT CVD and MT CVD is not about which is "better," but which is appropriate. It is a fundamental engineering decision that balances the need for a high-performance coating against the risk of damaging the underlying material (the substrate) with excessive heat.

The Role of Temperature in Chemical Vapor Deposition

To understand the difference between HT and MT processes, you must first grasp why temperature is so critical in CVD.

What is Chemical Vapor Deposition (CVD)?

CVD is a process used to apply high-performance coatings to a surface. In simple terms, precursor gases are introduced into a reactor chamber containing the part to be coated. Heat provides the necessary energy to trigger chemical reactions in the gases, causing a solid material—the coating—to form and deposit onto the part's surface.

Why Heat is the Primary Driver

The process temperature is the main "lever" an engineer controls. It directly dictates the energy available for the chemical reactions.

Higher temperatures generally lead to denser, more crystalline, and more strongly bonded coatings with superior hardness and wear resistance. However, this heat is also applied to the underlying part, which can have significant consequences.

Comparing HT CVD vs. MT CVD

The distinction between High-Temperature and Medium-Temperature CVD is a direct result of balancing coating quality with substrate integrity.

High-Temperature (HT) CVD: The Original Standard

Operating at 900°C to 1050°C, HT CVD is the classic method for creating exceptionally hard and wear-resistant coatings. This intense heat promotes the formation of highly stable and well-adhered layers.

It is the preferred method for materials that are not sensitive to high temperatures, such as cemented carbide cutting tools, where maximum performance is the primary goal.

Medium-Temperature (MT) CVD: The Versatile Compromise

MT CVD was developed specifically to coat materials that cannot withstand the extreme heat of the HT process. By operating in a lower range of 720°C to 900°C, it opens up CVD technology to a wider variety of substrates.

This is critical for heat-treated steels and other alloys that would lose their carefully engineered hardness, toughness, or dimensional accuracy if exposed to HT CVD temperatures. The resulting coatings still offer excellent performance, making MT CVD a versatile workhorse in the industry.

Understanding the Trade-offs

Choosing a process temperature is an exercise in managing competing priorities. The "cost" of a superior coating can be damage to the component it is meant to protect.

Substrate Integrity is Paramount

The most significant risk of high-temperature processing is altering the properties of the substrate. For a hardened steel component, exceeding its tempering temperature (the point at which it begins to soften) can ruin the part, regardless of how good the coating is.

MT CVD operates below the critical transformation temperatures for many common steels, preserving their bulk properties.

The Impact on Coating Properties

While MT CVD coatings are excellent, HT CVD generally produces coatings with higher adhesion and hardness due to the increased thermal energy available during deposition. The higher temperature facilitates better diffusion at the coating-substrate interface, creating a stronger metallurgical bond.

Expanding the Temperature Spectrum

The need to coat even more sensitive materials has driven the development of other CVD methods. Processes like Plasma-Enhanced CVD (PECVD) use plasma instead of high heat to drive reactions.

PECVD can operate at temperatures as low as 50°C to 400°C, enabling the coating of polymers, aluminum alloys, and complex electronics that would be destroyed by thermal CVD processes. This further illustrates that temperature control is the central challenge in coating applications.

Making the Right Choice for Your Application

Your decision must be guided by the limitations of your substrate material and your primary performance goal.

- If your primary focus is maximum hardness and wear resistance on a thermally stable substrate (like cemented carbide): HT CVD is the superior choice for its ability to create the most durable and well-bonded coatings.

- If your primary focus is coating heat-treated steels or other dimensionally critical components: MT CVD is the necessary choice to prevent softening, distortion, or other thermal damage to the substrate.

- If your primary focus is coating highly sensitive materials (like plastics, aluminum, or electronics): You must look beyond conventional thermal CVD to low-temperature alternatives like PECVD.

Ultimately, selecting the correct deposition temperature is the key to successfully balancing the desired coating properties with the physical limits of the component itself.

Summary Table:

| Process Type | Temperature Range | Key Applications |

|---|---|---|

| HT CVD | 900°C to 1050°C | Cemented carbide tools, high-wear resistance |

| MT CVD | 720°C to 900°C | Heat-treated steels, dimensionally critical parts |

| PECVD | 50°C to 400°C | Polymers, aluminum alloys, electronics |

Elevate your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our deep customization ensures precise temperature control for HT CVD, MT CVD, and beyond, helping you achieve optimal coating performance while protecting substrate integrity. Don't compromise on quality—contact us today to discuss how our solutions can enhance your research and production processes!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision