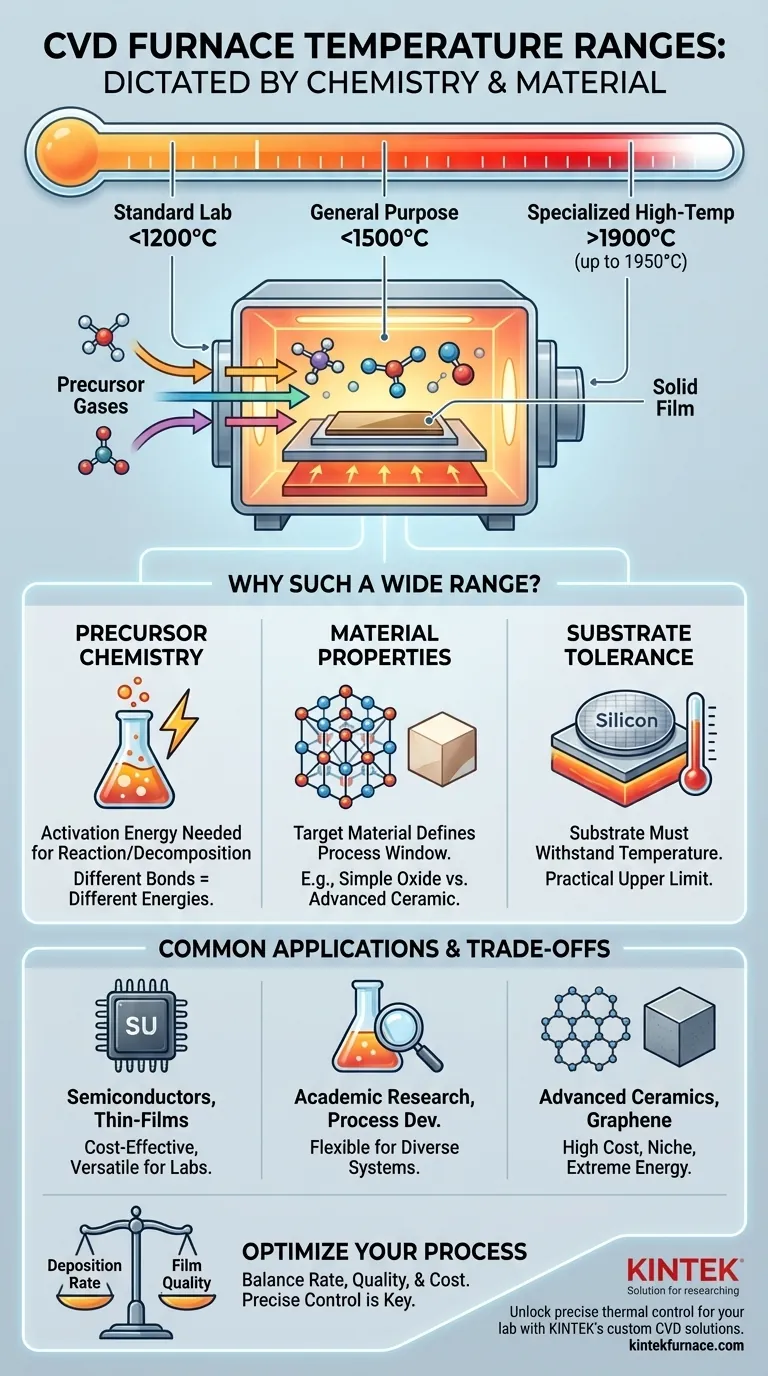

The operational temperature of a Chemical Vapor Deposition (CVD) furnace is not a single value but a wide spectrum dictated by the specific material being synthesized. While standard laboratory tube furnaces for CVD operate up to 1200°C, and general-purpose systems reach 1500°C, highly specialized units can achieve temperatures exceeding 1900°C, with some reaching approximately 1950°C for advanced material fabrication.

The required temperature for a CVD process is dictated entirely by the specific chemical reaction needed to deposit the desired material. There is no "one-size-fits-all" temperature; the precursor chemistry and target film properties determine the necessary thermal conditions.

Why Such a Wide Temperature Range?

The term "CVD furnace" describes a category of equipment designed for a specific process: creating a solid film from gaseous precursors. The vast temperature range reflects the diverse chemistry of the materials this process can create.

The Role of Precursor Chemistry

At its core, CVD is a controlled chemical reaction. Gaseous precursor chemicals are introduced into the furnace chamber, and the elevated temperature provides the activation energy needed for them to react or decompose.

This reaction results in the deposition of a solid thin film onto a substrate. Different chemical bonds require vastly different amounts of energy to break, directly translating to different temperature requirements.

Material Properties and Deposition Goals

The target material fundamentally defines the process window. Synthesizing a simple oxide film requires a completely different thermal environment than growing a robust ceramic or a crystalline carbon structure.

For example, processing certain zirconia materials via sintering (a related thermal process) requires 1400°C to 1600°C, while other ceramic processes can occur at just 700°C. CVD follows the same principle: the material dictates the heat.

Substrate Temperature Tolerance

The substrate—the material being coated—must be able to withstand the deposition temperature without melting, warping, or degrading. This often sets a practical upper limit on the process temperature.

High-temperature processes are therefore reserved for robust substrates like silicon wafers, sapphire, or advanced ceramics.

Common Operating Temperatures by Application

The temperature range can be broadly grouped by the complexity and performance requirements of the final material.

Standard and Laboratory Furnaces (up to 1500°C)

This is the most common category of CVD systems. Furnaces operating up to 1200°C cover a wide array of standard thin-film applications in semiconductors and materials science.

Laboratory tube furnaces, which can often reach 1500°C, provide the flexibility needed for a significant portion of academic research and process development.

High-Temperature Specialized Furnaces (up to 1950°C)

When the goal is to fabricate high-performance materials, extreme temperatures are necessary. These furnaces, capable of operating at over 1900°C, are used for niche research and industrial applications.

Examples include the synthesis of advanced refractory ceramics, specific carbon allotropes like graphene, or other materials requiring immense energy to form stable, high-quality films.

Understanding the Trade-offs

Choosing a temperature is not simply a matter of meeting a minimum threshold. It is a critical process parameter that involves balancing competing factors.

Temperature vs. Deposition Rate

Generally, higher temperatures increase the reaction rate, leading to faster film deposition. However, this relationship is not always linear and can be detrimental if not controlled.

Temperature vs. Film Quality

Excessive heat can cause unwanted side reactions or lead to poor crystalline structure. Precise temperature control is essential to ensure the deposited film has the desired purity, density, and morphology. The goal is a stable, controlled reaction, not just a fast one.

Cost and Complexity

There is a significant increase in cost and engineering complexity for furnaces that operate above 1500°C. They require more expensive heating elements (e.g., tungsten or graphite instead of silicon carbide), advanced insulation, and more robust cooling systems. The energy consumption is also substantially higher.

Making the Right Choice for Your Goal

The ideal thermal profile is determined by your specific scientific or industrial objective. Before selecting a system, clearly define your material and process requirements.

- If your primary focus is standard semiconductor or thin-film research: A furnace operating up to 1200-1500°C will cover the vast majority of common material systems.

- If your primary focus is developing novel, high-performance materials: You will likely require a specialized high-temperature furnace capable of reaching 1600°C to over 1900°C.

- If your primary focus is process optimization: Remember that the ideal temperature is a balance between deposition rate, film quality, and operational cost, not just the highest possible value.

Ultimately, the correct temperature is the one scientifically required by your specific precursor chemistry and material goal.

Summary Table:

| Temperature Range | Common Applications | Key Considerations |

|---|---|---|

| Up to 1200°C | Standard thin-film applications, semiconductor research | Cost-effective, versatile for labs |

| Up to 1500°C | Academic research, process development | Flexible for diverse material systems |

| Over 1900°C | Advanced ceramics, graphene synthesis | High cost, specialized for niche uses |

Unlock precise thermal control for your lab with KINTEK's advanced CVD furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is enhanced by deep customization to meet your unique experimental needs. Contact us today to discuss how our expertise can optimize your material synthesis and boost efficiency!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis