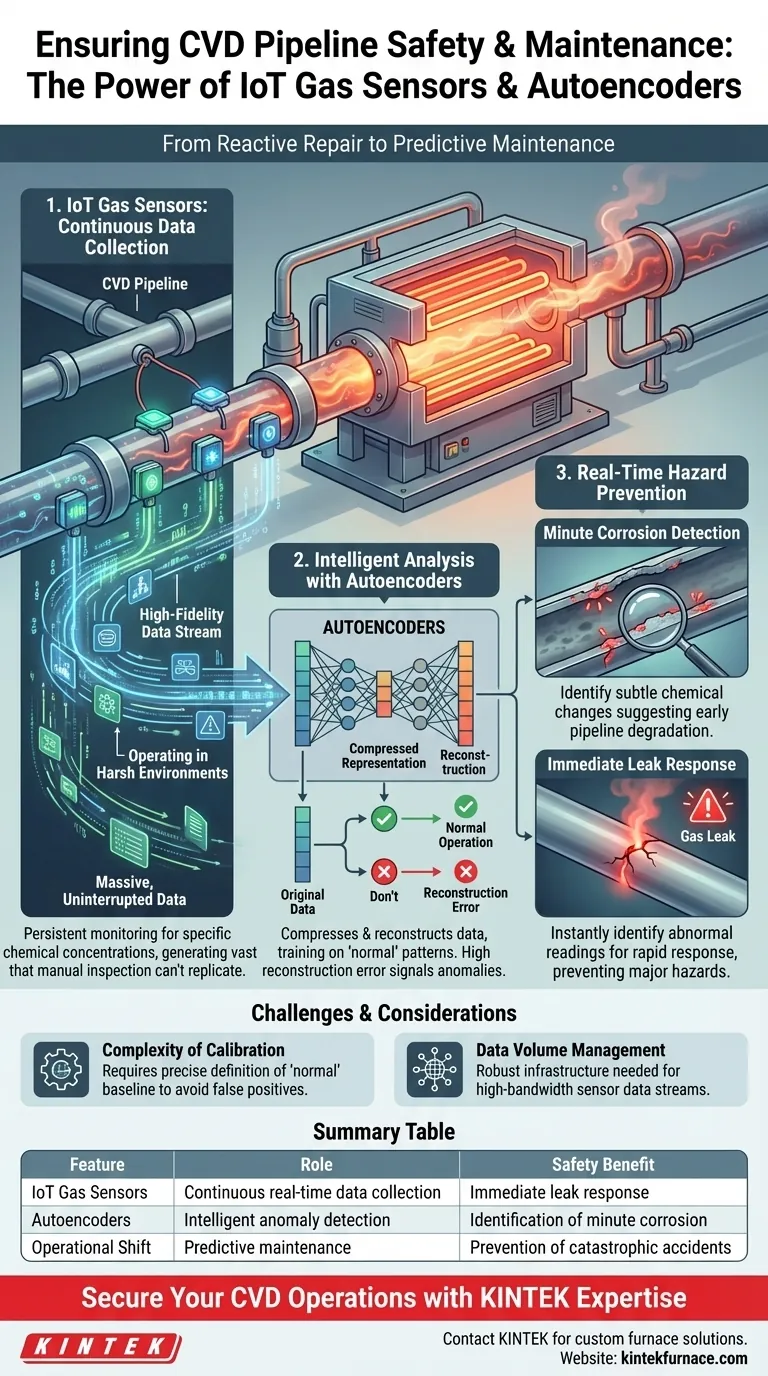

IoT gas sensors and Autoencoders work in tandem to create a high-precision safety system for Chemical Vapor Deposition (CVD) furnace pipelines. The IoT sensors continuously capture massive amounts of environmental data regarding chemical concentrations, while Autoencoders process this stream to identify subtle anomalies. By detecting deviations from standard operating patterns, this combination pinpoints minute corrosion or gas leaks in real-time, preventing catastrophic accidents in high-temperature processing environments.

The core value of this integration is the shift from reactive repair to predictive maintenance. By using Autoencoders to analyze sensor data, operators can identify and address pipeline integrity issues before they escalate into environmental hazards or safety failures.

The Role of Continuous IoT Monitoring

High-Fidelity Data Collection

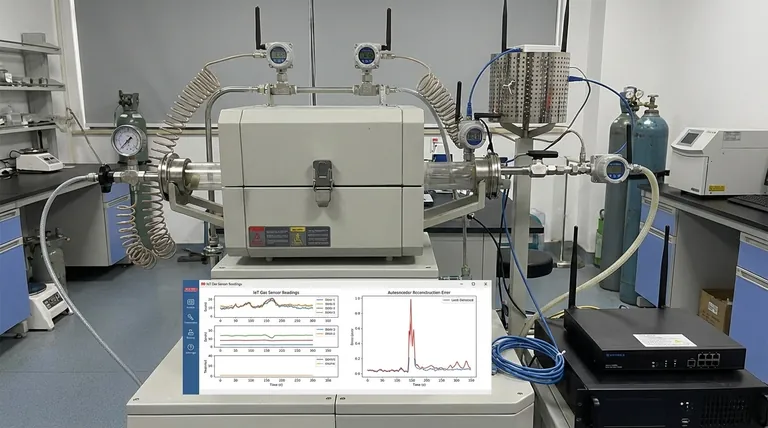

IoT-connected gas sensors are deployed directly around the CVD furnace pipelines. These devices operate continuously, monitoring the immediate environment for specific chemical concentrations.

Operating in Harsh Environments

CVD processes involve high temperatures and volatile chemicals. The sensors provide a persistent set of eyes on the hardware, generating a massive, uninterrupted stream of status data that manual inspection cannot replicate.

Intelligent Analysis with Autoencoders

Compressing and Reconstructing Data

Autoencoders are utilized to manage the massive volume of data generated by the sensors. Their primary function is to compress the input data and then attempt to reconstruct it.

Detecting the "Reconstruction Error"

The system is trained on standard, safe operating patterns. When the Autoencoder processes new data, it attempts to reconstruct it based on what it knows as "normal."

Flagging Anomalies

If the system cannot accurately reconstruct the data, it signals a high "reconstruction error." This error indicates a deviation from the norm, alerting operators to potential issues like gas leaks or structural changes.

Preventing Hazards Through Real-Time Detection

Identifying Minute Corrosion

Corrosion often starts subtly before causing a rupture. The sensitivity of this system allows for the detection of minute changes in chemical presence that suggest early-stage pipeline degradation.

Immediate Leak Response

By identifying abnormal readings the moment they occur, the system enables real-time responses to gas leaks. This capability is critical for preventing major environmental hazards associated with toxic chemical release.

Understanding the Challenges and Trade-offs

Complexity of Calibration

Implementing this solution requires precise calibration of the Autoencoders. If the "normal" baseline is not defined perfectly, the system may produce false positives or miss actual threats.

Data Volume Management

While Autoencoders compress data efficiently, the sheer volume of raw input from IoT sensors requires robust network infrastructure. Organizations must be prepared to handle high-bandwidth data streams reliably.

Making the Right Choice for Your Goal

To effectively implement this safety architecture, consider your specific operational priorities:

- If your primary focus is immediate hazard prevention: Prioritize high-sensitivity IoT sensors that can withstand the specific thermal limits of your CVD furnaces.

- If your primary focus is predictive maintenance: Invest heavily in the training phase of your Autoencoders to ensure they can distinguish between normal operational variance and true corrosion indicators.

The integration of IoT sensing and machine learning converts raw data into a definitive safety shield for your facility.

Summary Table:

| Feature | Role in CVD Safety & Maintenance |

|---|---|

| IoT Gas Sensors | Continuous, real-time data collection of chemical concentrations in harsh environments. |

| Autoencoders | Intelligent data compression and anomaly detection via reconstruction error analysis. |

| Safety Benefit | Immediate response to gas leaks and identification of minute pipeline corrosion. |

| Operational Shift | Transition from reactive repairs to data-driven predictive maintenance. |

| Key Outcome | Prevention of catastrophic accidents and reduction of environmental hazards. |

Secure Your CVD Operations with KINTEK Expertise

Ensure the highest safety standards for your high-temperature processes with KINTEK’s industry-leading technology. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or industrial needs.

Don't leave your pipeline integrity to chance. Partner with us to leverage cutting-edge equipment designed for reliability and precision. Contact KINTEK today to discuss your custom furnace solution and see how our advanced systems can enhance your research and production safety.

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis