A common and highly effective subtype of Chemical Vapor Deposition (CVD) furnace is the CVD tube furnace. This system works by creating a highly controlled, high-temperature environment within a cylindrical chamber. Precursor gases are introduced into this tube, where they react and decompose on a heated substrate, depositing a solid, high-purity thin film onto its surface. The tube's design is crucial for ensuring evenly distributed heat and gas flow, which is fundamental to achieving a uniform coating.

While the tube furnace is a common physical configuration, the true power of Chemical Vapor Deposition (CVD) lies in its fundamental process: using controlled chemical reactions in a gas phase to build high-purity, uniform thin films almost atom by atom.

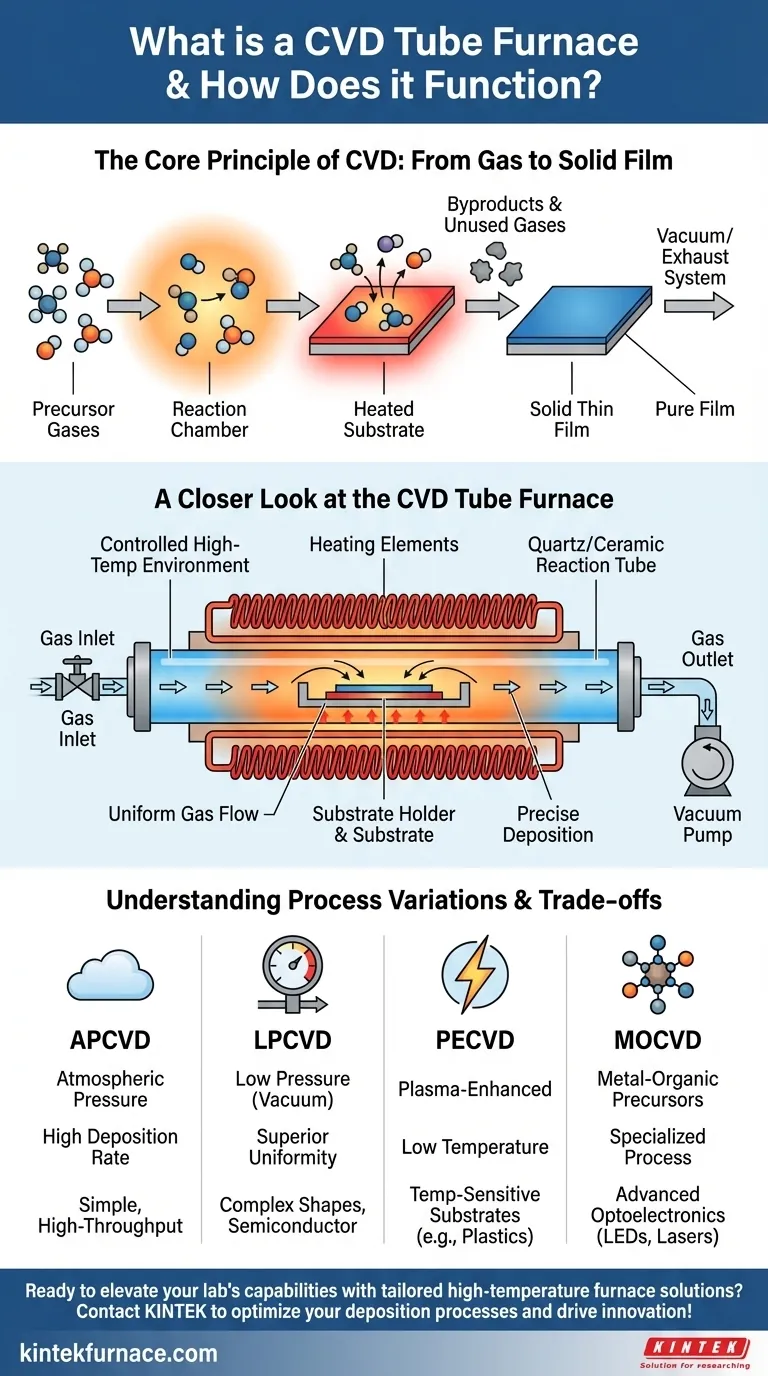

The Core Principle of Chemical Vapor Deposition (CVD)

To understand any CVD furnace, you must first understand the core process it is designed to facilitate. It is a method for building a solid material from a chemical gas.

From Gas to Solid Film

The process begins by introducing specific precursor gases into a reaction chamber. These gases contain the chemical elements that will make up the final film. The chamber is heated to a precise, high temperature, providing the energy needed to trigger a chemical reaction.

The Role of the Substrate

The reaction is designed to occur on the surface of a target object, known as the substrate. As the precursor gases react or decompose near the heated substrate, the desired material deposits onto its surface, gradually forming a solid, thin film.

Evacuating Byproducts

Any unused gases and chemical byproducts from the reaction are continuously removed from the chamber through an exhaust or vacuum system. This ensures the deposited film remains pure and free from contaminants.

A Closer Look at the CVD Tube Furnace

The tube furnace is a popular physical configuration for performing the CVD process due to its simplicity and effectiveness.

The Chamber's Design

As the name implies, the central feature is a cylindrical reaction tube, typically made of quartz or ceramic. This shape is naturally effective at promoting uniform gas flow and providing evenly distributed heat from external heating elements.

Key Functional Components

A CVD system is comprised of several critical parts working in concert:

- Reaction Source & Transport: Raw materials are heated or vaporized and precisely transported into the chamber as precursor gases.

- Reaction Chamber: The tube itself provides the contained, controlled environment for the deposition.

- Substrate: This is the material being coated, held at a specific temperature within the chamber.

Why This Configuration Is Common

The enclosed tube design excels at isolating the reaction. This minimizes contamination and allows for exceptionally precise control over the temperature, pressure, and gas composition—all of which are critical for creating films with superior quality and uniformity.

Understanding the Process Variations and Trade-offs

The "tube furnace" describes the physical setup, but the actual process run inside it can vary significantly. The choice of process is dictated by the material you want to deposit and the substrate you are using.

Pressure as a Critical Variable

Atmospheric Pressure CVD (APCVD) operates at normal atmospheric pressure, making it a relatively simple and high-deposition-rate process.

However, Low-Pressure CVD (LPCVD) uses a vacuum to reduce the chamber pressure. This enhances the uniformity of the film, especially on complex, three-dimensional substrates, because it allows the gases to diffuse more evenly.

The Plasma Advantage (PECVD)

Plasma-Enhanced CVD (PECVD) uses an electric field to generate plasma within the chamber. The plasma energizes the precursor gases, allowing the chemical reaction to occur at much lower temperatures than in traditional CVD. This is essential for depositing films on substrates that cannot withstand high heat, such as plastics or certain electronic components.

The Importance of Precursor Choice (MOCVD)

Metal-Organic CVD (MOCVD) is a specialized process defined by its use of metal-organic compounds as precursors. This technique is the cornerstone of the modern optoelectronics industry, used to create the complex compound semiconductor films required for high-performance LEDs and lasers.

Making the Right Choice for Your Goal

The best CVD method depends entirely on the desired film properties, substrate limitations, and production requirements.

- If your primary focus is high deposition rates and simplicity: APCVD is often the most straightforward approach for less demanding applications.

- If your primary focus is superior uniformity and coating complex shapes: LPCVD provides unmatched film quality and conformity, making it a standard in semiconductor manufacturing.

- If your primary focus is depositing on temperature-sensitive substrates: PECVD is the only viable option, enabling high-quality films without heat-related damage.

- If your primary focus is creating advanced optoelectronics: MOCVD is the industry standard for depositing the specific compound semiconductors required.

Understanding these core principles empowers you to select the precise deposition strategy that aligns with your material and application goals.

Summary Table:

| CVD Process Type | Key Feature | Best For |

|---|---|---|

| APCVD | Atmospheric pressure, high deposition rate | Simple, high-throughput applications |

| LPCVD | Low pressure, superior uniformity | Complex shapes, semiconductor manufacturing |

| PECVD | Low temperature with plasma | Temperature-sensitive substrates (e.g., plastics) |

| MOCVD | Metal-organic precursors | Advanced optoelectronics (e.g., LEDs, lasers) |

Ready to elevate your lab's capabilities with tailored high-temperature furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced CVD tube furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering high-purity, uniform thin films for applications in semiconductors, optoelectronics, and beyond. Contact us today to discuss how our solutions can optimize your deposition processes and drive innovation in your research or production!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations