In short, Chemical Vapor Deposition (CVD) is a fundamentally more complex process than Physical Vapor Deposition (PVD). This difference arises because PVD is a physical process of transferring material, similar to spray painting with atoms, while CVD is a chemical process that creates a new material on a surface through controlled reactions. The added variables of chemical precursors, gas flow, and reaction byproducts make CVD inherently more intricate to manage.

The core distinction is not about one process being universally "better," but about matching the right level of complexity to the task. PVD's relative simplicity offers exceptional purity and control for simpler geometries, whereas CVD's complexity is a necessary trade-off for achieving uniform coatings on intricate, three-dimensional surfaces.

The Fundamental Difference: Physical vs. Chemical

The root of the complexity difference lies in how the coating material arrives and forms on the substrate.

PVD: A Physical Transfer Process

Physical Vapor Deposition is a line-of-sight, mechanical process. A solid source material is vaporized (through methods like sputtering or evaporation) inside a high-vacuum chamber. These vaporized atoms travel in a straight line and condense onto the substrate, building up the thin film layer by layer.

The process is governed by a relatively small set of physical parameters: vaporization rate, substrate temperature, and deposition time. It is a direct transfer of the source material.

CVD: A Chemical Reaction Process

Chemical Vapor Deposition is a more indirect process. It introduces one or more volatile chemical gases, known as precursors, into a reaction chamber.

These gases decompose and react on or near a heated substrate, forming a new solid material that deposits as the film. This requires precise control over gas concentrations, flow rates, chamber pressure, and temperature gradients to drive the desired chemical reaction and avoid unwanted byproducts.

A Breakdown of Process Complexity

The difference in mechanism leads to significant variations in the practical complexity of equipment, control, and safety.

Control Parameters

PVD process control is comparatively straightforward. By managing power to the source and the deposition time, you can reliably control film thickness and composition.

CVD requires a delicate balance of multiple interdependent variables. Changing the gas mixture, pressure, or temperature can dramatically alter the film's chemical composition, growth rate, and structural properties, making process optimization a far more involved task.

Equipment and Environment

PVD systems are primarily high-vacuum chambers designed to ensure a clean path for vaporized atoms. The main challenge is achieving and maintaining the vacuum.

CVD reactors are more complex chemical processing systems. They must handle potentially hazardous, corrosive, or pyrophoric precursor gases, operate at very high temperatures, and manage the exhaust of reaction byproducts, adding significant safety and engineering overhead.

The Temperature Factor

Traditional thermal CVD often requires extremely high temperatures—from several hundred to over a thousand degrees Celsius—to provide the energy needed to break chemical bonds and initiate the reaction.

This high heat requirement limits the types of substrates that can be used. Variants like Plasma-Enhanced CVD (PECVD) reduce this temperature by using a plasma to excite the precursor gases, but this adds another layer of complexity: managing the plasma itself.

Understanding the Trade-offs

The complexity of each process directly correlates to its primary strengths and weaknesses. This is not a flaw, but an inherent trade-off you must choose between.

PVD: Simplicity, Purity, and Adhesion

Because PVD is a physical transfer in a clean vacuum, it excels at producing exceptionally pure films with high density and strong adhesion.

However, its line-of-sight nature is its main limitation. It struggles to uniformly coat the inside of channels, undercuts, or complex 3D shapes, a phenomenon known as poor step coverage or conformality.

CVD: Conformality at the Cost of Complexity

The gas-phase nature of CVD is its greatest advantage. Precursor gases can flow into and react on all exposed surfaces of a complex part, resulting in a highly conformal coating that is uniform even on intricate geometries.

The trade-off is the potential for impurities. Incomplete reactions or the incorporation of byproducts from the precursor gases can sometimes compromise the purity of the final film.

Making the Right Choice for Your Application

Selecting the right method requires aligning your primary goal with the inherent capabilities of the process.

- If your primary focus is high-purity films on relatively flat surfaces: PVD is the more direct and controllable path due to its simpler, physical mechanism.

- If your primary focus is uniformly coating complex, 3D geometries: CVD is the necessary choice, as its chemical, gas-based nature provides the superior conformality required for the task.

- If your primary focus is coating temperature-sensitive substrates: A specialized, low-temperature PVD process or a more complex variant like PECVD are your primary options.

Ultimately, understanding the source of each process's complexity empowers you to select the right tool for your specific engineering challenge.

Summary Table:

| Aspect | PVD | CVD |

|---|---|---|

| Process Type | Physical transfer (e.g., sputtering) | Chemical reaction with gases |

| Key Control Parameters | Vaporization rate, substrate temperature, deposition time | Gas concentrations, flow rates, chamber pressure, temperature gradients |

| Equipment Complexity | High-vacuum chambers for clean paths | Complex reactors handling hazardous gases and byproducts |

| Temperature Requirements | Lower, suitable for various substrates | High (thermal CVD) or lower with plasma (PECVD) |

| Coating Conformality | Poor on complex 3D shapes | Excellent, uniform on intricate geometries |

| Film Purity | High, with strong adhesion | Potential impurities from reactions |

Struggling to choose between PVD and CVD for your lab's coating needs? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD systems, tailored for diverse laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental requirements—whether you need uniform coatings on complex parts or high-purity films. Contact us today to optimize your process and achieve superior results!

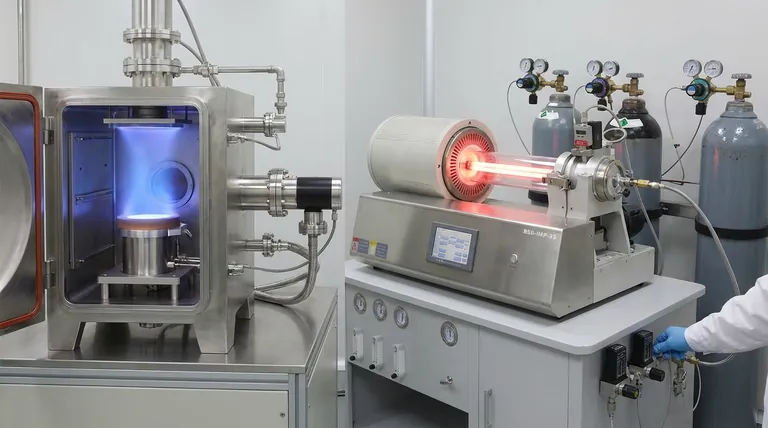

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials

- What is the difference between PVD and PECVD? Choose the Right Thin-Film Coating Technology

- What are the uses of CVD? Unlocking Advanced Materials & Coatings

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK