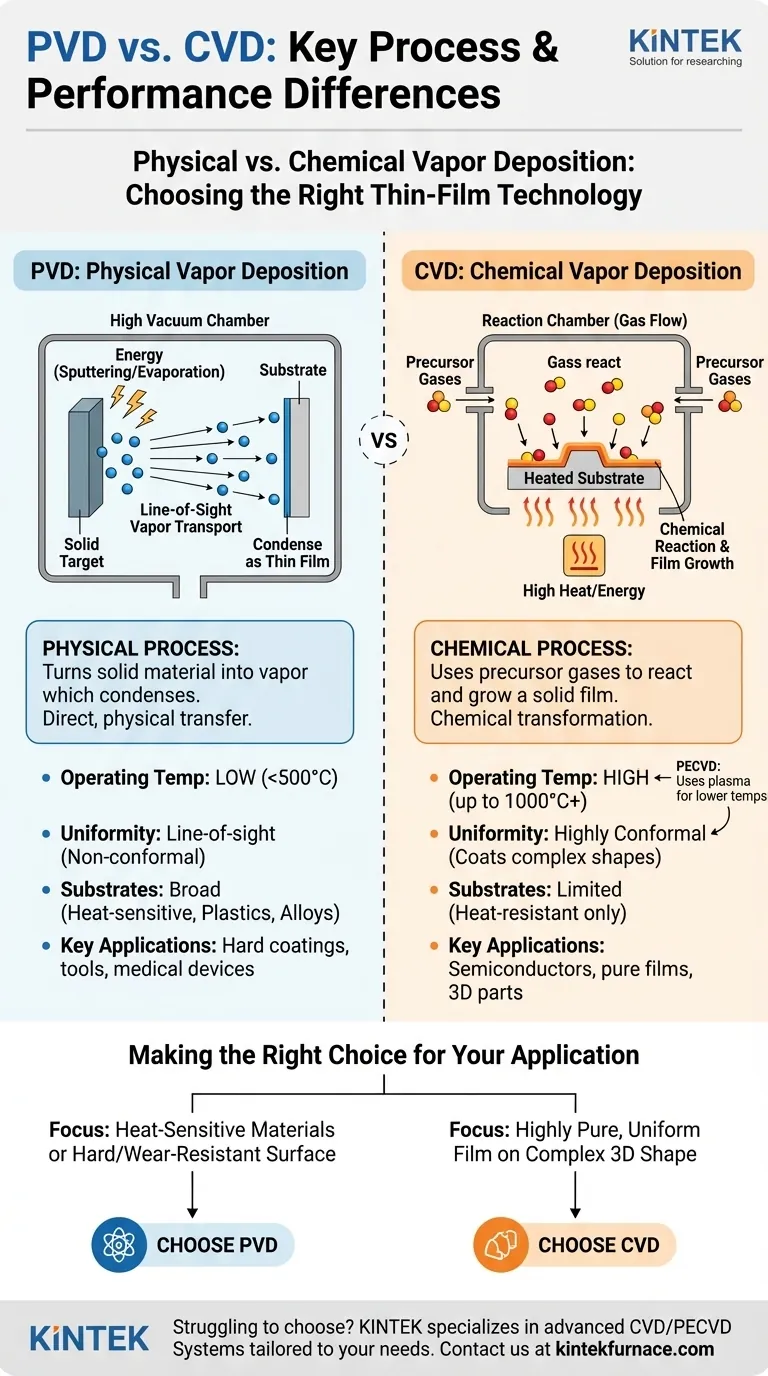

At its core, the difference between Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) comes down to the state of the source material and how it's applied. PVD is a physical process that turns a solid material into a vapor which then condenses onto a substrate in a vacuum. In contrast, CVD is a chemical process that uses precursor gases to react and form a solid film on the substrate's surface, often at high temperatures.

The choice between PVD and CVD is not about which is universally "better," but which is correct for the specific application. PVD is fundamentally a physical, line-of-sight process ideal for hard coatings on heat-sensitive parts, while CVD is a chemical growth process that excels at creating highly pure, uniform films on complex shapes.

The Fundamental Process: Physical vs. Chemical

The names "Physical Vapor Deposition" and "Chemical Vapor Deposition" directly describe their core mechanisms. Understanding this distinction is the first step in selecting the right technology.

PVD: A Physical "Sputtering" or "Evaporation" Process

In PVD, the coating material starts as a solid target inside a high-vacuum chamber.

This solid material is bombarded with energy—either through high-energy ions (sputtering) or heat (evaporation)—causing atoms to be ejected from the target.

These vaporized atoms travel in a straight line through the vacuum and condense as a thin film onto the part being coated. It is a direct, physical transfer from a solid source to the final film.

CVD: A Chemical "Growth" Process

CVD begins with volatile precursor gases being introduced into a reaction chamber. The part to be coated is placed inside this chamber.

Energy, typically in the form of high heat, is applied to initiate chemical reactions between the gases.

These reactions cause a new, solid material to form and "grow" directly on the substrate's surface, building up a uniform thin film. The coating is a product of a chemical transformation, not a physical transfer.

Core Operational Differences

The physical versus chemical nature of these processes leads to significant differences in their operating conditions and the characteristics of the resulting coatings.

Operating Temperature and Its Implications

CVD typically requires very high temperatures (several hundred to over a thousand degrees Celsius) to drive the necessary chemical reactions. This severely limits the types of materials that can be coated, as many plastics or heat-treated metals would be damaged.

PVD operates at much lower temperatures, often below 500°C. This makes it suitable for a far wider range of substrates, including plastics, alloys, and previously heat-treated components.

An important exception is Plasma-Enhanced CVD (PECVD), which uses plasma instead of high heat to energize the precursor gases, allowing for deposition at much lower temperatures.

Coating Conformality and Uniformity

Because CVD relies on a gas that can flow around and into features, it excels at creating a highly conformal and uniform coating, even on complex 3D shapes and internal surfaces.

PVD is a line-of-sight process. Like spray paint, it coats what it can "see." This makes it challenging to achieve uniform coverage on intricate geometries without complex part rotation and fixturing.

Process Complexity and Environment

PVD operates in a high vacuum, which is mechanically straightforward but requires robust pumping systems. The process itself is physically simple with few chemical hazards.

CVD processes use volatile and often hazardous precursor gases. This adds a layer of chemical complexity and requires significant safety protocols and handling procedures.

Understanding the Trade-offs

Neither process is a universal solution. The advantages of one are often the disadvantages of the other, creating a clear set of trade-offs based on your goal.

Film Purity and Adhesion

CVD can produce films of exceptionally high purity, as the chemical reactions can be precisely controlled to form a specific compound. This is critical for applications like semiconductor manufacturing.

The high temperatures of thermal CVD also promote strong chemical bonding and diffusion between the film and the substrate, resulting in excellent adhesion.

Substrate Compatibility

This is PVD's key advantage. Its low processing temperature preserves the integrity of the underlying material, making it the default choice for coating temperature-sensitive parts like polymer optics or hardened steel tools.

Cost and Application Variety

CVD can be adapted to a vast range of materials and applications, from semiconductor wafers to large-scale industrial components. For some high-volume applications, Atmospheric Pressure CVD (APCVD) can be very cost-effective.

PVD is dominant in fields requiring hard, wear-resistant, or decorative coatings, such as cutting tools (TiN), medical implants, and consumer electronics.

Making the Right Choice for Your Application

The decision requires matching the process capabilities to your engineering and product requirements.

- If your primary focus is coating heat-sensitive materials or achieving a hard, wear-resistant surface: PVD is often the superior choice due to its lower process temperatures and ability to deposit hard ceramic compounds efficiently.

- If your primary focus is creating a highly pure, uniform film on a complex 3D shape: CVD is typically the better solution, as the gaseous precursors can conformally coat intricate geometries that PVD cannot reach.

- If your primary focus is balancing the conformality of CVD with low-temperature requirements: Investigate Plasma-Enhanced CVD (PECVD), as it provides a critical bridge between the two technologies.

Understanding these core principles moves the decision from a simple comparison to a strategic choice aligned with your specific engineering goals.

Summary Table:

| Aspect | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (e.g., sputtering, evaporation) | Chemical (gas reactions) |

| Operating Temperature | Low (<500°C) | High (up to 1000°C+) |

| Coating Uniformity | Line-of-sight, less conformal | Highly conformal, even on complex shapes |

| Substrate Compatibility | Broad (heat-sensitive materials) | Limited (high-temperature resistant) |

| Key Applications | Hard coatings, tools, medical devices | Semiconductors, pure films, 3D parts |

Struggling to choose between PVD and CVD for your lab? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD Systems, tailored to meet your unique experimental needs. Our deep customization capabilities ensure precise, efficient thin-film deposition for industries like semiconductors and materials science. Contact us today to optimize your process and achieve superior results!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition