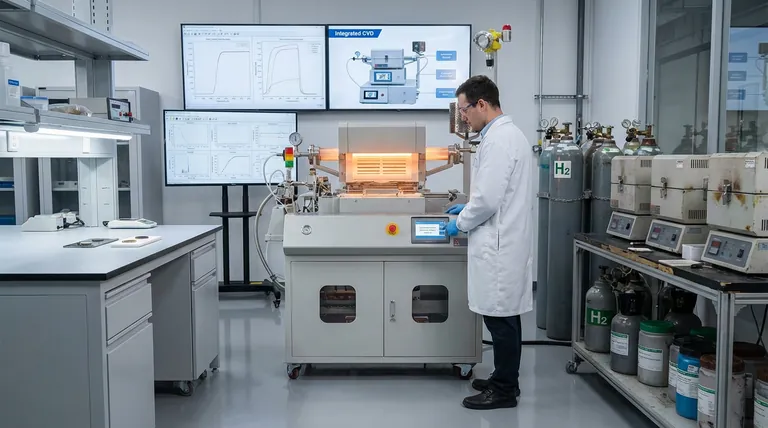

Integrated Chemical Vapor Deposition (CVD) carbonization systems offer a decisive economic advantage by merging pyrolysis and nanomaterial growth into a single, simultaneous process. This integration drastically lowers operational costs by shortening production times by 81% to 90% and reducing carrier gas consumption to less than 1% of what traditional multi-step methods require.

The core economic value is driven by the elimination of expensive input variables. By removing the need for precious metal catalysts and costly reducing gases like hydrogen, the integrated CVD system lowers the barrier to entry for both laboratory research and large-scale industrial manufacturing.

Streamlining Operational Efficiency

The Impact of Simultaneous Processing

Traditional methods separate carbonization into distinct phases, each requiring its own setup and ramp-up time. An integrated CVD system combines pyrolysis and nanomaterial growth into one step. This consolidation is the primary driver for the massive reduction in total operation time.

Drastic Reduction in Cycle Time

Time is a critical cost factor in manufacturing. The integrated system achieves an 81% to 90% reduction in operation time compared to conventional methods. This increase in throughput allows for significantly higher production volumes within the same timeframe.

Lowering Energy Consumption

Energy costs in high-temperature processing are substantial. By shortening the operation time so drastically, the system naturally consumes far less energy. You are no longer paying to maintain high temperatures for extended, multi-step durations.

Eliminating High-Cost Consumables

Removing Precious Metal Catalysts

Standard hierarchical carbon fiber production often relies on expensive catalysts to facilitate growth. The integrated CVD process functions effectively without precious metal catalysts. This removes a major variable cost that typically scales poorly in mass production.

Reducing Gas Dependency

Gas consumption is often an overlooked operating expense. This system minimizes carrier gas usage to less than 1% of traditional requirements. Furthermore, it completely eliminates the need for hydrogen, a costly reducing gas, simplifying the supply chain and improving safety.

Understanding the Implementation Trade-offs

Equipment Specificity

While operating costs are lower, an integrated system requires specialized reactor design to handle simultaneous processes. Unlike multi-step processes where standard, separate furnaces might suffice, this approach requires equipment capable of managing complex thermal and chemical profiles in a single chamber.

Process Parameter Sensitivity

In a multi-step process, you can optimize pyrolysis and growth independently. In an integrated system, these variables are coupled. Achieving the correct balance requires precise control; if the environment is optimized for pyrolysis but not growth, the final material quality may suffer.

Making the Right Choice for Your Goal

To determine if an integrated CVD system aligns with your production targets, consider your scale and budget priorities.

- If your primary focus is Rapid Prototyping: The 81-90% reduction in cycle time allows for faster iteration cycles and quicker data gathering in a research setting.

- If your primary focus is Industrial Scalability: The elimination of hydrogen and precious metal catalysts significantly improves profit margins by removing the most expensive recurring material costs.

By moving to an integrated CVD architecture, you are effectively trading process complexity for substantial savings in time, energy, and raw materials.

Summary Table:

| Economic Metric | Traditional Multi-Step Process | Integrated CVD System | Savings/Benefit |

|---|---|---|---|

| Production Time | 100% (Baseline) | 10% - 19% | 81% - 90% Reduction |

| Carrier Gas Usage | High (100%) | < 1% | > 99% Reduction |

| Catalyst Costs | High (Precious Metals) | None Required | Major Cost Elimination |

| Reducing Gases | Hydrogen Required | Not Needed | Lower Risk & Cost |

| Energy Efficiency | Low (Extended Heating) | High (Rapid Processing) | Significant Savings |

Maximize Your Lab’s ROI with KINTEK Specialized CVD Systems

Don't let inefficient, multi-step processes drain your resources. KINTEK empowers researchers and industrial manufacturers with cutting-edge, customizable high-temperature furnaces designed for complex chemical profiles.

Backed by expert R&D and precision manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique carbonization and nanomaterial growth needs. Transition to an integrated architecture today to reduce energy costs, eliminate expensive catalysts, and accelerate your time-to-market.

Ready to optimize your production efficiency? Contact our engineering team today for a tailored solution that fits your budget and technical requirements!

References

- Sura Nguyen, Sergio O. Martínez‐Chapa. Synthesis and characterization of hierarchical suspended carbon fiber structures decorated with carbon nanotubes. DOI: 10.1007/s10853-024-09359-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How does Chemical Vapor Deposition (CVD) differ from Physical Vapor Deposition (PVD)? Choose the Right Thin-Film Process

- What are the main differences between PVD and CVD coating techniques? Choose the Right Method for Your Application

- Why is a mixture of Argon and Hydrogen used for 2D In2Se3? Optimize Growth and Prevent Oxidation

- How does the CVD process alter substrate properties? Enhance Durability, Conductivity, and More

- What are the main applications of CVD in semiconductor fabrication? Essential for Building Modern Microchips

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What are the applications of CVD method? Unlock High-Performance Thin Films & Coatings

- How does a Molecular Turbo Pump contribute to ZTO thin film quality? Master High-Vacuum Deposition Precision