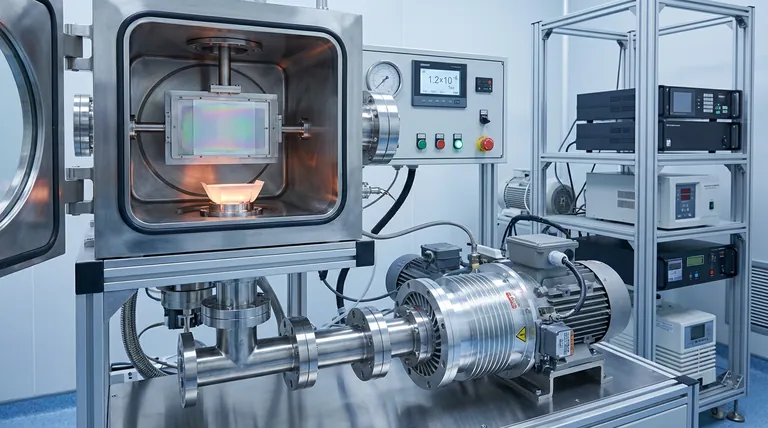

A Molecular Turbo Pump is the foundational component for depositing high-quality Zinc Tin Oxide (ZTO) thin films, specifically tasked with driving the chamber pressure down to a high vacuum state of $10^{-6}$ torr. By removing the vast majority of air molecules, the pump ensures that evaporated ZTO atoms travel directly to the substrate without collision and arrive free from atmospheric contaminants.

The Core Insight In vacuum evaporation, the quality of the film is defined by what isn't in the chamber. The Molecular Turbo Pump eliminates microscopic obstacles and chemical impurities, allowing the source material to form a dense, pure, and uniform structure on the substrate.

The Physics of High Vacuum Deposition

Reaching the Critical Pressure Threshold

The primary function of the Molecular Turbo Pump is to evacuate the chamber to a pressure of $10^{-6}$ torr.

This level of vacuum is classified as "high vacuum." It represents a state where the density of gas molecules is low enough to fundamentally change how particles move within the system.

Maximizing the Mean Free Path

At atmospheric pressure, air is crowded; atoms constantly collide with one another.

The pump reduces the number of residual air molecules, thereby increasing the mean free path. This is the average distance an evaporated atom can travel before hitting something else.

In a high vacuum, this path becomes sufficiently long to exceed the distance from the source to the substrate. This ensures the ZTO atoms travel in a straight, ballistic trajectory rather than being scattered by background gas.

Ensuring Molecular Flow

When the mean free path is long, the system achieves a state of molecular flow.

This allows the evaporated gas-phase atoms to travel consistently toward the target. This supports the formation of a film with uniform thickness and structure.

Protecting Chemical Integrity

Eliminating Contamination Sources

ZTO films are sensitive to their chemical environment during growth.

The Molecular Turbo Pump removes oxygen, nitrogen, and water vapor from the chamber. If these residual gases remained, they would react with the evaporated ZTO atoms.

Preserving ZTO Purity

By preventing oxidation and the inclusion of other impurities, the pump ensures the stoichiometry of the deposited layer matches the intended design.

This is critical for maintaining the specific electrical and optical properties required of Zinc Tin Oxide layers.

The Role of the Pump in the Wider System

Supporting Thermal Evaporation

The pump creates the environment necessary for the Molybdenum Boat to function correctly.

As the boat heats the ZTO powder to sublimation using high electrical current, the vacuum ensures the resulting vapor expands efficiently. Without the pump, the heat transfer and evaporation dynamics would be erratic.

Enabling Optimal Geometry

The system typically maintains a fixed source-to-substrate distance, often around 10 cm.

The vacuum provided by the turbo pump ensures that this 10 cm gap is not a barrier. It allows the atoms to traverse this specific distance without losing energy to collisions, reducing the risk of low deposition rates.

Understanding the Trade-offs

Sensitivity to Debris

Molecular Turbo Pumps operate at extremely high rotational speeds.

They are highly sensitive to physical debris or sudden bursts of pressure. If the vacuum chamber is not vented properly or if particulate matter enters the pump, the blades can be destroyed instantaneously.

Vibration Management

Because these pumps rely on high-speed rotors, they can introduce micro-vibrations to the system.

While usually minimal, these vibrations must be isolated in highly sensitive experiments to prevent physical defects in the thin film structure during the deposition process.

Making the Right Choice for Your Goal

To optimize your ZTO deposition process, consider your specific experimental priorities:

- If your primary focus is Film Purity: Ensure your pump consistently maintains $10^{-6}$ torr or lower to eliminate all potential chemical contaminants like oxygen.

- If your primary focus is Structural Density: Verify that the vacuum level is sufficient to create a mean free path longer than your source-to-substrate distance (e.g., >10 cm) to prevent scattering.

Ultimately, the Molecular Turbo Pump is not just an exhaust mechanism; it is the gatekeeper of your film's atomic structure.

Summary Table:

| Feature | Impact on ZTO Thin Film Quality |

|---|---|

| Vacuum Level ($10^{-6}$ torr) | Eliminates atmospheric contaminants (O2, N2, H2O) for high purity. |

| Mean Free Path | Enables ballistic trajectory of atoms; prevents scattering and collisions. |

| Molecular Flow | Ensures uniform film thickness and consistent atomic structure. |

| Pressure Stability | Supports efficient sublimation from Molybdenum boats without interference. |

Elevate Your Thin Film Deposition with KINTEK Expertise

Precision in Zinc Tin Oxide (ZTO) fabrication starts with a superior vacuum environment. KINTEK provides state-of-the-art laboratory solutions tailored for high-performance material science.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of equipment including:

- Advanced Vacuum Systems & Turbo Pumps for pristine deposition environments.

- Customizable Muffle, Tube, Rotary, and CVD Furnaces for precise thermal processing.

Whether you are optimizing film purity or structural density, our team is ready to customize systems to your unique research needs. Contact KINTEK today to discuss your laboratory requirements and see how our high-temperature and vacuum technologies can transform your results.

References

- Ashish Khandelwal, K. S. Sharma. Effect of Different Compositions of Mixed Metal Oxides (Zinc Oxide and Tin Oxide) on Structural and Optical Properties for the Application of Window Layers in Solar Cells. DOI: 10.3329/jsr.v16i1.64157

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is precise temperature control of the precursor delivery system essential in CVD for hollow silica particles?

- What is a CVD system? Achieve Atomic-Level Precision for High-Performance Coatings

- What types of materials can be deposited using CVD in microfabrication? Explore Versatile Thin Films for Your Devices

- What are the advantages of using a CVD system? Achieve Precision and Uniformity for Complex Thin Films

- What are the overall advantages of CVD technology across industries? Unlock High-Performance Material Engineering

- Why is quartz commonly used in CVD chambers for graphene production? Key Benefits for High-Purity Synthesis

- What is the function of Atomic Layer Deposition (ALD) equipment? Precision Engineering of Ni/BaZrO3/MAO Catalysts

- How does the CVD process begin? Master Precise Film Deposition from the Start