Precise temperature control is the fundamental variable that governs vapor stability. In Chemical Vapor Deposition (CVD), maintaining liquid precursors like tetraethyl orthosilicate (TEOS) at a specific temperature (e.g., 65°C) is the only way to generate a stable and consistent vapor flow. Without this thermal stability, the deposition process becomes erratic and unpredictable.

Control the temperature to control the material. By locking the precursor at a set temperature, you ensure uniform vapor saturation. This stability allows the carrier gas to transport a predictable amount of material, directly enabling the precise regulation of the silica shell's thickness.

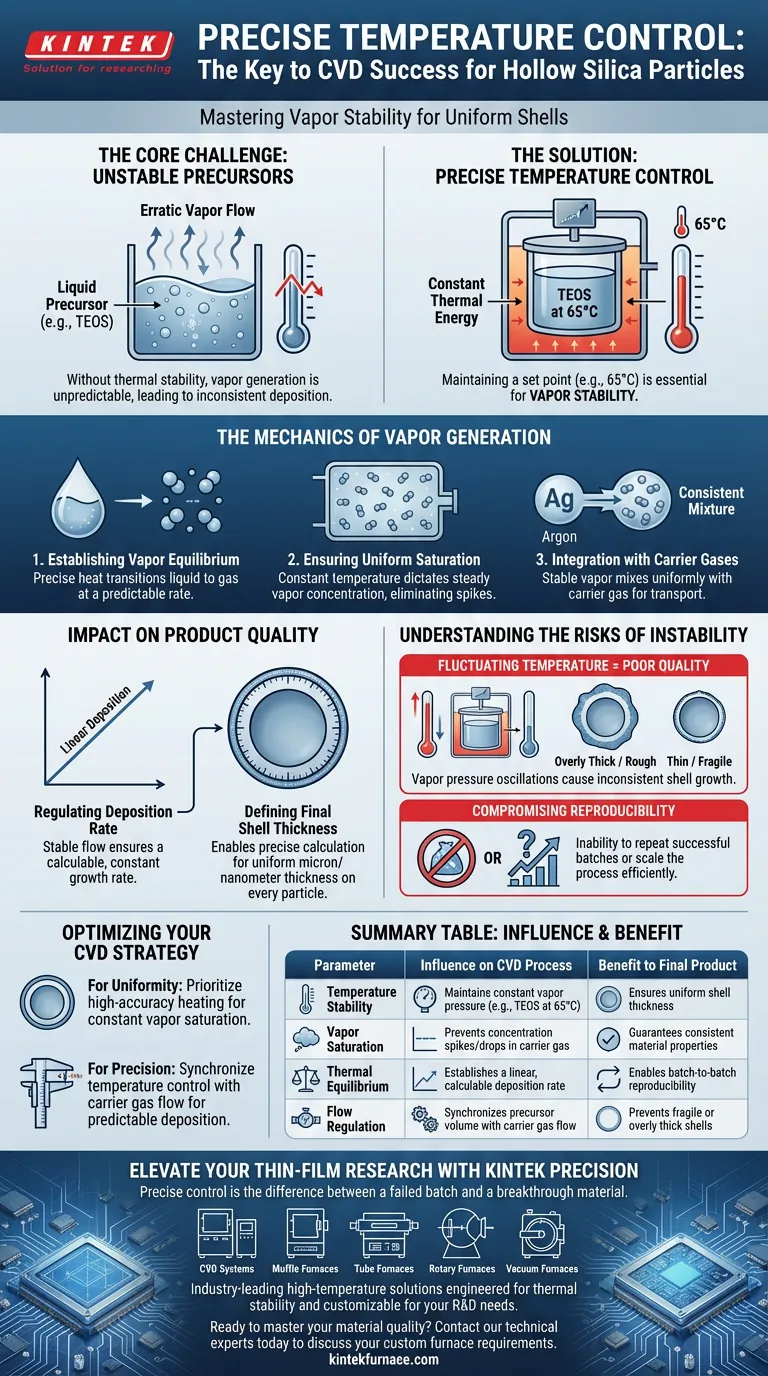

The Mechanics of Vapor Generation

Establishing Vapor Equilibrium

The precursor delivery system must heat liquid precursors to a precise set point. For TEOS, this is often maintained at 65°C.

This specific thermal energy is required to transition the liquid into a gas at a predictable rate. If the temperature drifts, the rate of evaporation changes immediately.

Ensuring Uniform Saturation

Temperature directly dictates vapor saturation. By holding the temperature constant, the gas phase above the liquid remains at a steady concentration.

This eliminates spikes or drops in the amount of reactant available for the chemical reaction downstream.

Integration with Carrier Gases

Once the vapor is generated, a steady flow of a carrier gas, such as argon, sweeps through the system.

This gas picks up the precursor vapor. Because the vapor generation is thermally stabilized, the argon creates a consistent mixture rather than alternating between rich and lean concentrations.

Impact on Product Quality

Regulating Deposition Rate

The rate at which the silica shell grows on the hollow particles is determined by how much precursor reaches the surface over time.

Stable temperature ensures a constant flow of reactants. This turns the deposition rate into a linear, calculable variable rather than a fluctuating unknown.

Defining Final Shell Thickness

The ultimate measure of success in this CVD process is the final thickness of the silica shell layer.

Precise temperature control allows engineers to calculate exactly how long the process must run to achieve a specific micron or nanometer thickness. It ensures every particle in the batch receives the same coating.

Understanding the Risks of Instability

The Danger of Vapor Pressure Fluctuations

If the precursor delivery system lacks precise control, vapor pressure will oscillate.

A slight rise in temperature can lead to an excess of precursor, causing the shell to grow too thick or form rough surfaces. Conversely, a drop in temperature starves the reaction, resulting in thin, fragile shells.

Compromising Reproducibility

Without strict thermal regulation, repeating a successful batch becomes impossible.

You effectively lose the ability to scale the process, as the deposition rate will vary from run to run based on minor environmental changes.

Optimizing Your CVD Strategy

To achieve the best results in hollow silica particle production, align your controls with your specific manufacturing goals.

- If your primary focus is shell uniformity: Prioritize high-accuracy heating elements to keep the TEOS strictly at 65°C, ensuring constant vapor saturation.

- If your primary focus is thickness precision: Synchronize your temperature control with the argon carrier gas flow rate to lock in a predictable deposition timeline.

Mastering the thermodynamics of the precursor delivery is the first step toward mastering the quality of your final material.

Summary Table:

| Parameter | Influence on CVD Process | Benefit to Final Product |

|---|---|---|

| Temperature Stability | Maintains constant vapor pressure (e.g., TEOS at 65°C) | Ensures uniform shell thickness |

| Vapor Saturation | Prevents concentration spikes/drops in argon carrier gas | Guarantees consistent material properties |

| Thermal Equilibrium | Establishes a linear, calculable deposition rate | Enables batch-to-batch reproducibility |

| Flow Regulation | Synchronizes precursor volume with carrier gas flow | Prevents fragile or overly thick shells |

Elevate Your Thin-Film Research with KINTEK Precision

Precise control is the difference between a failed batch and a breakthrough material. KINTEK provides industry-leading high-temperature solutions—including CVD systems, Muffle, Tube, Rotary, and Vacuum furnaces—specifically engineered to deliver the thermal stability required for complex precursor delivery.

Our systems are fully customizable to meet your unique R&D and manufacturing needs, backed by expert engineering to ensure your deposition rates remain predictable and your shell thicknesses remain precise.

Ready to master your material quality? Contact our technical experts today to discuss your custom furnace requirements.

Visual Guide

References

- Hirokazu Katsui, Mikinori Hotta. Preparation of hollow silica particles by template method via chemical vapor deposition. DOI: 10.2109/jcersj2.23114

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- In what way are CVD systems applied to gas purification? Engineer Advanced Catalysts for Cleaner Synthesis Gas

- How do quartz tube dimensions influence MoS2 CVD synthesis? Optimize Flow for High-Quality Monolayers

- What role does the gas flow control system play in Ga2O3 growth? Achieve High-Performance Nanowire Precision

- Why do PVD systems require high-purity (99.999%) metal targets? Ensure Peak Coating Performance

- What is chemical vapor phase deposition? Unlock High-Performance Thin Films for Your Lab

- What is the purpose of chemical vapour deposition? To Grow High-Performance Materials from a Vapor

- Why are CVD furnaces considered important in modern technology? Unlock Precision in Thin-Film Manufacturing

- How does a CVD system facilitate in-situ graphene synthesis? High-Quality Coatings for Flexible Electronics