PVD systems require high-purity (99.999%) metal targets primarily to guarantee the chemical consistency and physical integrity of the deposited thin film. This "5N-grade" standard is essential because even microscopic impurities in the source material act as contaminants that introduce structural defects, compromising the coating's density and protective qualities.

Core Insight: The purity of the target material dictates the limit of the coating's performance. Using 99.999% purity targets eliminates micro-impurities that otherwise cause reduced hardness, poor corrosion resistance, and structural defects in high-performance applications.

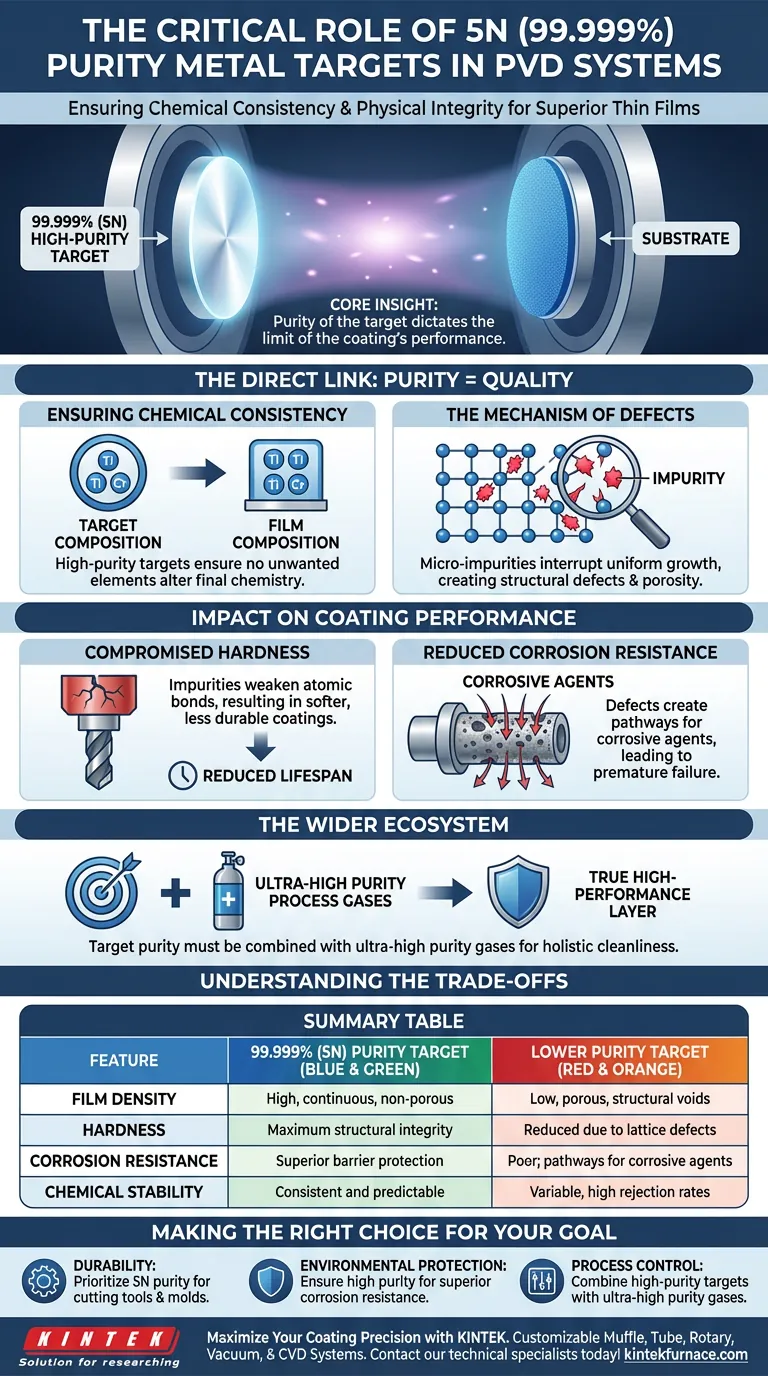

The Direct Link Between Purity and Quality

Ensuring Chemical Consistency

In Physical Vapor Deposition, the material from the target is transferred directly to the substrate. Consequently, the chemical composition of the target defines the composition of the film.

To maintain consistent physical properties across the entire coated surface, the source material—often metals like titanium or chromium—must be chemically uniform. High-purity targets ensure that no unwanted elements alter the intended chemistry of the final layer.

The Mechanism of Defects

When a target contains micro-impurities, these contaminants do not simply disappear during the vacuum process. Instead, they are incorporated into the growing film.

These impurities interrupt the uniform growth of the crystal lattice. This disruption introduces defects that compromise the density of the coating, creating a layer that is structurally porous rather than solid and continuous.

Impact on Coating Performance

Compromised Hardness

For applications such as cutting tools and molds, surface hardness is the primary performance metric.

Defects caused by target impurities weaken the atomic bonds within the film. This results in a coating that is softer and less durable, significantly reducing the lifespan of the tool it is meant to protect.

Reduced Corrosion Resistance

A primary function of PVD coatings is to act as a barrier against environmental damage.

Micro-impurities create weak points and microscopic voids within the film's density. These defects act as pathways for corrosive agents to penetrate the coating and attack the substrate, leading to premature failure.

The Role of the Wider Ecosystem

Pairing with Process Gases

Target purity does not operate in isolation. The industry standard requires a holistic approach to cleanliness.

To achieve a true high-performance protective layer, 5N-grade targets must be combined with ultra-high purity process gases. If the gas introduces contaminants, the benefits of the high-purity target are negated.

Understanding the Trade-offs

The Cost of Inconsistency

While high-purity targets represent a strict standard, deviations from this 99.999% requirement introduce immediate risks.

The trade-off for using lower-grade materials is a loss of predictability. Lower purity introduces variables that result in fluctuating film density and adhesion issues. In industrial settings, this inconsistency leads to a higher rate of part rejection and tool failure.

Making the Right Choice for Your Goal

Selecting the correct target purity is about matching material quality to performance requirements.

- If your primary focus is Durability: Prioritize 5N (99.999%) purity targets to maximize hardness and wear resistance for cutting tools and molds.

- If your primary focus is Environmental Protection: Ensure high target purity to achieve the high film density required for superior corrosion resistance.

- If your primary focus is Process Control: Combine high-purity targets with ultra-high purity gases to eliminate defect variables from the deposition environment.

Ultimately, the integrity of your protective coating is strictly limited by the purity of your source material.

Summary Table:

| Feature | 99.999% (5N) Purity Target | Lower Purity Target |

|---|---|---|

| Film Density | High, continuous, and non-porous | Low, porous with structural voids |

| Hardness | Maximum structural integrity | Reduced due to lattice defects |

| Corrosion Resistance | Superior barrier protection | Poor; pathways for corrosive agents |

| Chemical Stability | Consistent and predictable | Variable with high rejection rates |

Maximize Your Coating Precision with KINTEK

Don't let impurities compromise your research or industrial output. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-purity materials and advanced thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. All our laboratory high-temp furnaces are fully customizable to meet your unique thin-film deposition and material processing needs.

Ready to elevate your film quality? Contact us today to consult with our technical specialists!

Visual Guide

References

- André Paulo Tschiptschin. PROCESSOS SOB VÁCUO USADOS PARA TRATAMENTOS TÉRMICOS E DE SUPERFÍCIE DE AÇOS E LIGAS ESPECIAIS. DOI: 10.17563/rbav.v43i1.1262

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How is CVD technology applied in the glass coating industry? Achieve Durable, High-Performance Glass Coatings

- How can fixturing improve the CVD coating process? Boost Uniformity and Efficiency in Your Lab

- What is the function of H2 in DLI-PP-CVD for MoS2? Optimize Crystalline Quality and Purity

- What is low temperature vapor deposition? A Guide to Coating Heat-Sensitive Materials

- How do IoT gas sensors and Autoencoders contribute to CVD furnace safety? Enhance Pipeline Integrity and Monitoring

- How does a high-precision MFC affect MoS2 growth? Mastering Epitaxial Quality in CVD

- What types of diamond and carbon nanofilms can be prepared using CVD? Explore the Full Spectrum from Diamond to Graphene

- What are the characteristics of freestanding monolithic materials produced by CVD furnaces? Achieve Superior Purity and Performance