Freestanding monolithic materials produced by Chemical Vapor Deposition (CVD) are defined by their exceptional purity and a solid structure that is almost entirely free of voids. The highly controlled CVD process synthesizes reproducible bulk materials with performance characteristics that are often superior to those made by conventional methods.

The core value of CVD for producing monolithic materials lies in its bottom-up, atom-by-atom assembly. This precise control results in a near-perfect solid, engineered for exceptional purity and density, unlocking performance levels that are unattainable through traditional melting, casting, or powder metallurgy techniques.

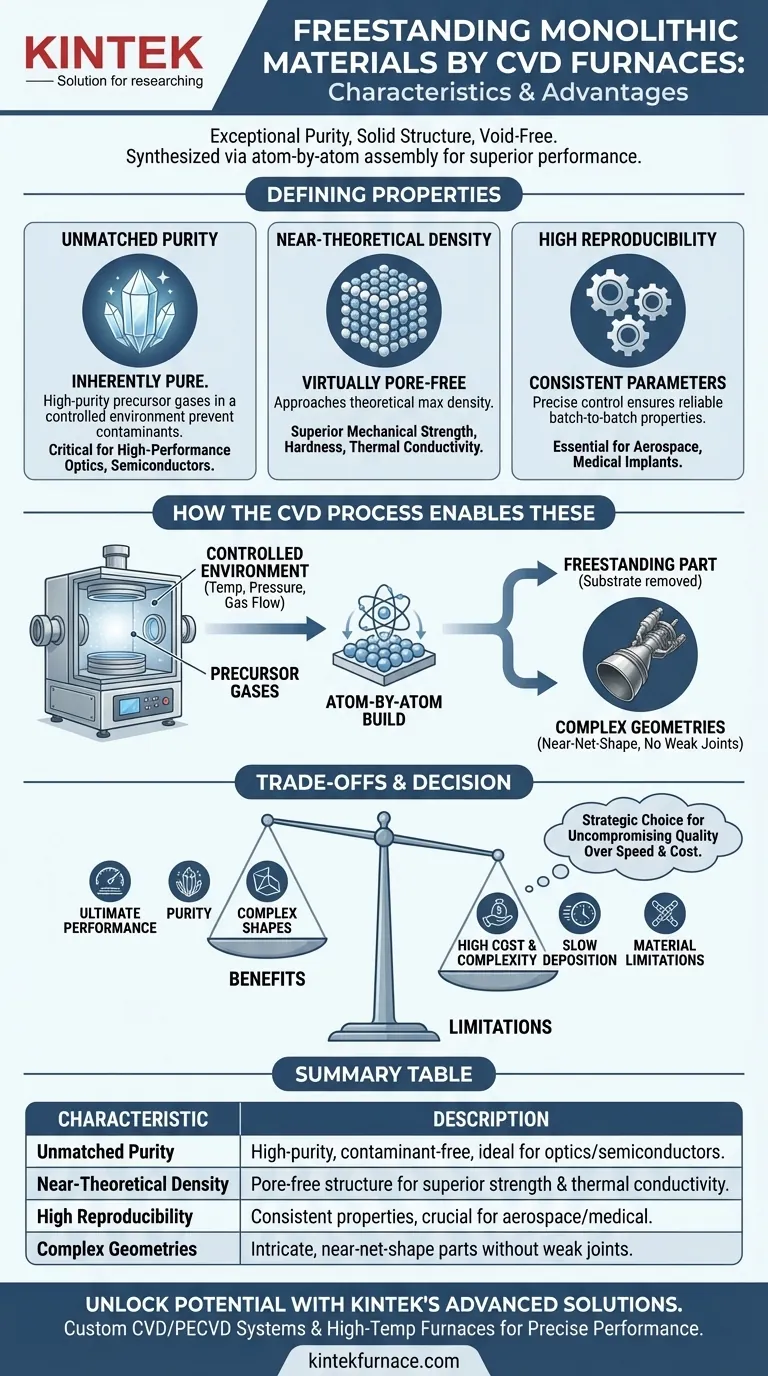

The Defining Properties of CVD Monoliths

The unique environment inside a CVD furnace directly imparts several key characteristics to the final freestanding material. These properties are not incidental; they are the direct result of the manufacturing process itself.

Unmatched Purity

Materials produced via CVD are inherently pure. The process starts with high-purity precursor gases, and the controlled deposition environment effectively prevents the introduction of contaminants.

This extreme purity is critical for applications where even trace impurities can degrade performance, such as in high-performance optics, semiconductor components, or corrosion-resistant coatings.

Near-Theoretical Density

CVD monoliths are known for being exceptionally dense, often approaching the theoretical maximum density of the material. This means they are virtually free of the microscopic pores or voids found in materials made by sintering or casting.

This lack of porosity directly translates to superior mechanical properties, including higher strength, hardness, and fracture toughness. It also enhances thermal conductivity, as there are no voids to impede the flow of heat.

High Reproducibility

The precise, automated control over the CVD process parameters—such as temperature, pressure, and gas flow rates—ensures a high degree of consistency.

This means that the properties of the material can be reliably reproduced from one production run to the next. For industries like aerospace or medical implants, this batch-to-batch consistency is a non-negotiable requirement.

How the CVD Process Enables These Characteristics

The properties of the final product are a direct reflection of the process used to create it. The flexibility and precision of modern CVD furnaces are what make these high-performance materials possible.

The Role of a Controlled Environment

CVD furnaces operate as highly controlled chemical reactors. The ability to maintain precise high temperatures and pressures, along with exact control over the gas phase composition, is fundamental.

This control allows for the selective deposition of the desired material while excluding unwanted elements, which is the mechanism that ensures high purity and density.

Building from the Atom Up

Unlike melting and solidifying, CVD builds the material one atomic or molecular layer at a time. Gaseous precursors decompose on a heated surface, leaving behind a solid deposit.

This methodical, additive process is what allows the material to grow into a fully dense solid, conforming perfectly to the shape of the substrate or mandrel it is grown on. Once the desired thickness is achieved, this substrate can be removed, leaving a "freestanding" monolithic part.

Creating Complex Geometries

Because the material is deposited onto a surface, CVD can produce complex, near-net-shape components that would be extremely difficult or impossible to create through conventional machining.

This allows for the creation of monolithic parts like rocket nozzles, crucibles, or intricate optical components without the weak points associated with welds or joints.

Understanding the Trade-offs

While CVD produces materials with superior properties, it is not the ideal solution for every application. Understanding its limitations is key to making an informed decision.

High Cost and Complexity

CVD furnaces are sophisticated, expensive pieces of equipment. The precursor gases can also be costly and may require specialized handling procedures, adding to the operational expense.

Slow Deposition Rates

Building a material atom by atom is an inherently slow process. For thick, bulk components, a single production run can take days or even weeks. This makes CVD unsuitable for low-cost, high-volume production.

Material Limitations

The CVD process is dependent on the availability of suitable chemical precursors that are volatile at manageable temperatures and pressures. This means not all materials can be readily synthesized using this method.

Choosing CVD for Your Application

The decision to use CVD-produced monoliths should be based on a clear understanding of your project's primary objective.

- If your primary focus is ultimate performance and purity: CVD is often the only viable method for creating monolithic components that approach the theoretical limits of a material.

- If your primary focus is producing complex, near-net-shape parts with high strength: The ability of CVD to create dense, non-porous structures on intricate forms makes it a superior choice over machining or casting.

- If your primary focus is cost-effective, high-volume manufacturing: The slow deposition rates and high operational costs of CVD mean you should likely explore alternative methods like sintering or casting.

Ultimately, choosing CVD for monolithic materials is a strategic decision to prioritize uncompromising quality and performance over speed and cost.

Summary Table:

| Characteristic | Description |

|---|---|

| Unmatched Purity | High-purity materials free from contaminants, ideal for optics and semiconductors. |

| Near-Theoretical Density | Virtually pore-free structure for superior strength, hardness, and thermal conductivity. |

| High Reproducibility | Consistent properties across batches, crucial for aerospace and medical implants. |

| Complex Geometries | Enables creation of intricate, near-net-shape parts without weak joints. |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique experimental needs. Our strong deep customization capability ensures precise performance for applications requiring high purity, density, and reproducibility. Contact us today to discuss how our solutions can enhance your material synthesis and drive innovation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing