In short, proper fixturing transforms the Chemical Vapor Deposition (CVD) process from a variable art into a repeatable science. By securely holding components, a well-designed fixture ensures consistent coating coverage, prevents part damage during handling and processing, improves the quality of surface preparation, and dramatically enhances overall coating efficiency.

The core challenge of CVD is managing a gas-phase reaction uniformly across all part surfaces. Fixturing is not merely about holding parts; it is a critical tool for controlling the process environment to guarantee that every component receives the same treatment, resulting in a predictable, high-quality coating.

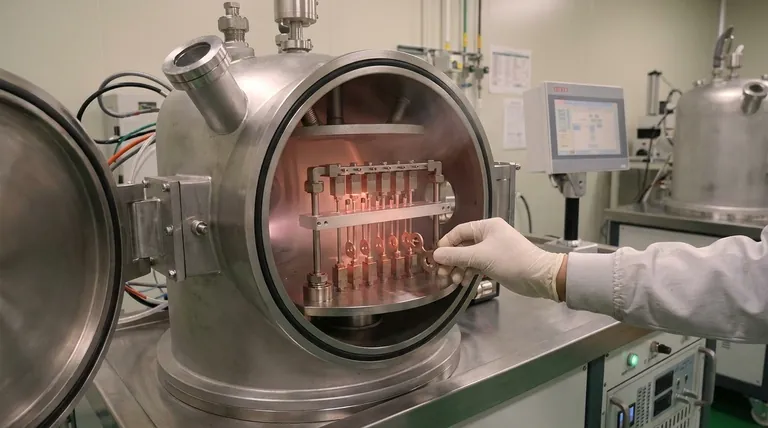

Why Fixturing is More Than Just a Holder

To understand the impact of fixturing, you must first understand the CVD environment. The process occurs under vacuum at elevated temperatures, where gaseous chemicals (precursors) react and bond to a component's surface.

The CVD Process Demands Precision

Unlike line-of-sight processes like PVD, CVD can coat complex internal and external geometries because the gas can flow around the part.

This advantage, however, is also a challenge. Without precise control, gas flow, concentration, and temperature can vary, leading to inconsistent coating thickness and quality.

Ensuring Uniform Gas Exposure

A primary role of fixturing is to manage how precursor gases interact with the parts. Fixtures are designed to hold components in an optimal orientation and spacing.

This prevents parts from touching or creating "shadows" that block gas flow, which would result in thinner or non-existent coating in those areas. Advanced fixtures can even incorporate features like gas diffusers to help distribute the gas evenly throughout the chamber.

Maintaining Thermal and Chemical Stability

The CVD reaction is highly sensitive to temperature. Fixtures must be designed to heat up uniformly with the parts, preventing hot or cold spots that would alter the coating reaction rate on the part surface.

Furthermore, the fixture itself must be stable and not react with the process chemistry, as this could contaminate the chamber and compromise the coating's integrity.

Improving Batch Efficiency

Effective fixturing allows for a higher density of parts to be coated in a single cycle without sacrificing quality.

By maximizing the use of the reactor volume, you can increase throughput and lower the cost per part, directly improving the economic efficiency of the coating operation.

Understanding the Trade-offs and Design Considerations

While essential, fixturing is not without its challenges. A poorly designed fixture can create more problems than it solves.

Contact Points and Inevitable Masking

Every point where a fixture touches a part will be a "no-coat" zone. The fixture design must ensure these contact points are placed on non-critical surfaces where the absence of coating is acceptable.

Material Compatibility is Non-Negotiable

The material used for the fixture must be able to withstand the high temperatures and corrosive chemical environment of the CVD process.

Using the wrong material can lead to fixture degradation, part contamination, or an unintended reaction with the precursor gases, ruining the entire batch.

The Impact on Gas Flow Dynamics

A dense or poorly designed fixture can impede gas flow, creating turbulence or dead zones within the reactor.

This undermines the primary goal of uniformity, leading to the very thickness variations you are trying to prevent. The fixture must be designed as part of the total gas flow system.

Balancing Cost and Complexity

Highly customized fixtures for complex parts provide the best results but come at a higher initial cost. For simpler geometries or less critical applications, a more universal and cost-effective fixture may be sufficient.

Making the Right Choice for Your Goal

Your fixturing strategy should be directly aligned with your primary production objective.

- If your primary focus is maximizing throughput: Prioritize fixture designs that safely increase part density per batch while maintaining adequate spacing for gas flow.

- If your primary focus is coating complex geometries: Invest in custom-engineered fixtures that orient parts to ensure uniform gas exposure to all critical surfaces, including internal channels.

- If your primary focus is absolute process consistency: Select fixtures made from highly stable, non-reactive materials that guarantee thermal uniformity and minimize any risk of contamination.

Ultimately, viewing fixturing as an integral part of the reaction environment, not just a holder, is the key to unlocking the full potential of your CVD process.

Summary Table:

| Fixturing Benefit | Key Impact |

|---|---|

| Uniform Coating Coverage | Ensures consistent thickness and quality across all part surfaces |

| Part Damage Prevention | Secures components during handling and high-temperature processing |

| Improved Surface Preparation | Enhances gas flow and thermal stability for better coating adhesion |

| Increased Batch Efficiency | Maximizes reactor use to lower costs and boost throughput |

Ready to optimize your CVD process with expert fixturing solutions? KINTEK specializes in advanced high-temperature furnace systems, including CVD/PECVD Systems, and offers deep customization to meet your unique needs. Our strong R&D and in-house manufacturing ensure precise, reliable results for your laboratory. Contact us today to discuss how we can enhance your coating efficiency and quality!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key properties of diamond that make it a promising semiconductor material? Unlock Next-Gen Electronics

- What are the uses of chemical vapour deposition? Powering Modern Tech from Chips to Solar Panels

- What is Hot-filament Chemical Vapor Deposition (HFCVD)? Achieve High-Quality Thin Films with Precision Control

- What is the use of CVD machine? Transform Surfaces with Atomic-Level Precision

- What is a CVD machine? Build High-Performance Materials from Gas with Precision