In short, Chemical Vapor Deposition (CVD) is applied directly onto the glass surface during the high-temperature float-glass manufacturing process. By introducing precursor gases like silane and nitrogen, a chemical reaction is triggered that deposits a thin, exceptionally durable, and uniform silicon-based coating. This coating becomes chemically bonded to the glass, fundamentally enhancing its hardness, wear resistance, and optical properties while preventing oxidation.

The core principle is not to simply add a layer on top of the glass, but to integrate a high-performance coating as an intrinsic part of the glass during its formation, resulting in a significantly more resilient and functional final product.

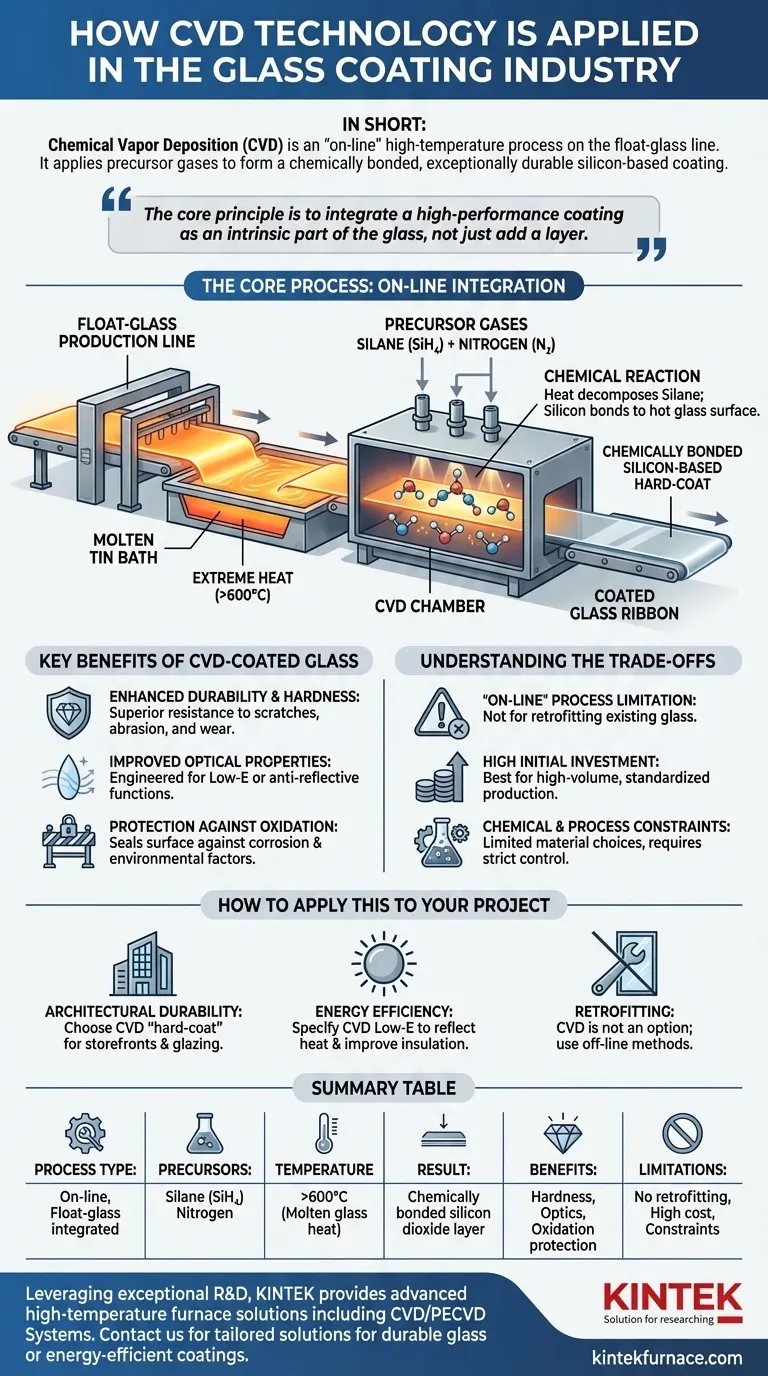

The Core Process: How CVD Integrates with Glass Manufacturing

CVD is an "on-line" process, meaning it happens as the glass is being made. This integration is the key to its effectiveness and durability.

The Float-Glass Production Line

The process takes place on the float line, where a continuous ribbon of molten glass floats on a bath of molten tin. This environment provides the extreme heat necessary to drive the CVD reaction without any external energy source.

The Chemical Reaction

As the glass ribbon moves through a controlled atmosphere chamber, a precise mixture of precursor gases is introduced above its surface. For a standard hard-coat, this is typically silane gas (SiH₄) mixed with a carrier gas like nitrogen.

Forming the Coating

The intense heat from the molten glass (over 600°C) causes the silane gas to decompose. The silicon atoms then react with oxygen and bond directly to the hot glass surface, forming an extremely hard and uniform layer of silicon dioxide or a related silicon compound.

Key Benefits of CVD-Coated Glass

The properties of a CVD coating are a direct result of it being chemically bonded to the glass substrate at a molecular level.

Enhanced Durability and Hardness

The resulting silicon-based layer is significantly harder than the glass itself. This creates a "hard-coat" that provides superior resistance to scratches, abrasion, and general wear and tear, making it ideal for high-traffic applications.

Improved Optical Properties

Because the CVD process deposits an incredibly thin and uniform layer, it can be engineered to control how light interacts with the glass. This is used to create low-emissivity (Low-E) coatings that reflect infrared heat or anti-reflective coatings for specialized optics.

Protection Against Oxidation and Corrosion

The dense, non-porous coating acts as a chemical barrier. It seals the glass surface, protecting it from environmental factors like moisture and atmospheric chemicals that can cause corrosion or staining over time.

Understanding the Trade-offs

While powerful, the CVD process has specific characteristics that define its use cases. It is not a universally applicable solution.

An "On-Line" Process Limitation

Because CVD for glass is performed on the float line, it cannot be applied to existing glass panes or finished products. The coating is part of the initial manufacturing, unlike other methods like sputtering (PVD), which are "off-line" processes.

High Initial Investment

Integrating a CVD system into a multi-million dollar float-glass line is a significant capital expenditure. This makes the technology suitable for high-volume production of standardized coated glass rather than small, custom batches.

Chemical and Process Constraints

The choice of coating materials is limited to those whose precursor gases will react properly at the temperatures available on the float line. This requires careful chemical engineering and stringent process control to ensure safety and consistent quality.

How to Apply This to Your Project

Your choice depends entirely on the performance you need from the glass itself.

- If your primary focus is architectural durability: Choose CVD "hard-coat" glass for storefronts, railings, and exterior glazing where scratch resistance and longevity are critical.

- If your primary focus is energy efficiency: Specify CVD Low-E coated glass, which uses this durable coating to reflect heat and improve the building's insulation performance.

- If your primary focus is retrofitting existing glass: CVD is not an option; you must look to off-line coating technologies or film applications.

By selecting CVD-coated glass, you are choosing a material where the protective surface is not just an addition, but an integral part of the glass itself.

Summary Table:

| Aspect | Details |

|---|---|

| Process Type | On-line, integrated with float-glass manufacturing |

| Key Precursors | Silane gas (SiH₄) and nitrogen carrier gas |

| Temperature | Over 600°C, using heat from molten glass |

| Coating Result | Chemically bonded silicon dioxide layer |

| Main Benefits | Enhanced hardness, wear resistance, improved optics, oxidation protection |

| Limitations | Not for retrofitting, high initial investment, material constraints |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're developing durable architectural glass or energy-efficient coatings, our expertise in CVD technology can help you achieve superior results. Contact us today to discuss how we can support your project with tailored solutions!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films