Chemical Vapor Deposition (CVD) systems are primarily applied to gas purification through the synthesis of advanced catalysts and specialized filtration membranes. By exerting precise control over gas flow, temperature, and pressure, these systems engineer materials specifically designed to remove harmful impurities—such as hydrogen sulfide (H2S), carbon dioxide (CO2), and chloride compounds—from synthesis gas streams.

The core value of CVD in this context is its ability to deposit highly functional materials with controlled porosity and uniformity. This allows for the creation of barriers and catalysts that actively strip corrosive elements from gas, protecting critical downstream infrastructure.

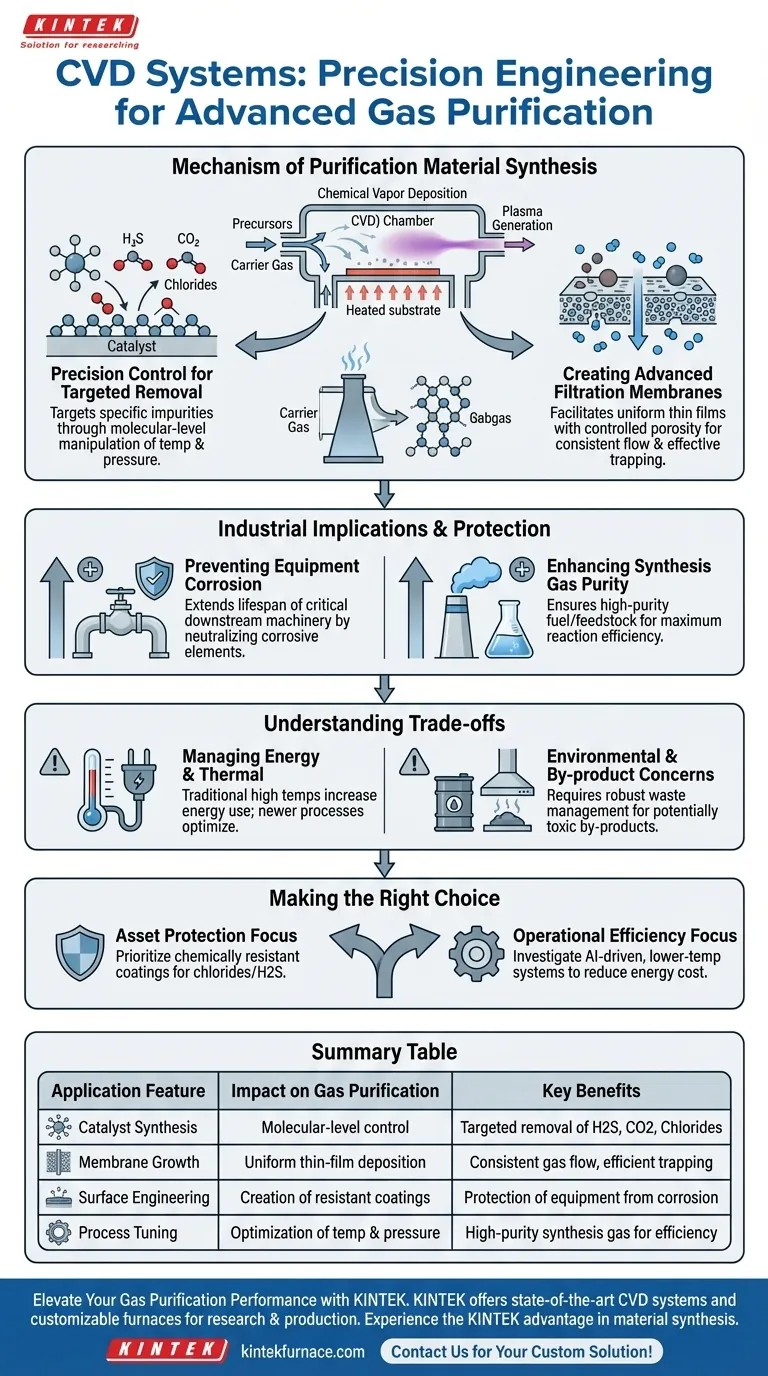

The Mechanism of Purification Material Synthesis

Precision Control for Targeted Removal

The effectiveness of a gas purification system relies on the chemical properties of the filter medium. CVD systems allow engineers to manipulate the deposition process at a molecular level.

By finely tuning the temperature and pressure within the reaction chamber, the system creates materials that react specifically with target impurities like chlorides or sulfur compounds.

Creating Advanced Filtration Membranes

Beyond simple surface coatings, CVD is used to develop complex filtration membranes. The process facilitates the growth of thin films with uniform thickness and controlled porosity.

This structural uniformity is essential for ensuring that gas flow remains consistent while contaminants are effectively trapped or neutralized.

Industrial Implications and Protection

Preventing Equipment Corrosion

The primary industrial objective of applying CVD to gas purification is asset protection. Impurities such as H2S and chlorides are highly corrosive to industrial machinery.

By synthesizing materials that effectively remove these compounds upstream, CVD-derived technologies significantly extend the lifespan of downstream equipment.

Enhancing Synthesis Gas Purity

For industries relying on synthesis gas, purity is paramount for reaction efficiency. CVD systems provide the technology to create the catalysts necessary to achieve high-purity outputs.

This ensures that the fuel or feedstock gas entering subsequent processes is free of contaminants that could degrade performance.

Understanding the Trade-offs

Managing Energy and Thermal Requirements

Historically, CVD processes have required high operating temperatures to achieve the necessary chemical reactions. This can lead to increased energy consumption and higher operational costs.

While the industry is trending toward lower-temperature processes and high-vacuum conditions, the energy footprint remains a consideration for facility planning.

Environmental and By-product Concerns

While CVD creates materials that solve pollution problems, the CVD process itself can generate toxic by-products depending on the precursors used.

Operators must implement their own robust waste management and safety protocols to mitigate the environmental impact of the manufacturing process itself.

Making the Right Choice for Your Goal

When evaluating CVD technologies for gas purification applications, consider your specific operational targets:

- If your primary focus is asset protection: Prioritize CVD processes that specialize in synthesizing chemically resistant coatings to neutralize chlorides and H2S before they reach sensitive equipment.

- If your primary focus is operational efficiency: Investigate newer CVD systems that utilize AI-driven optimization and lower operating temperatures to reduce the energy cost of producing your filtration materials.

CVD technology transforms gas purification from a passive filtration method into a precision-engineered defense system for your industrial infrastructure.

Summary Table:

| Application Feature | Impact on Gas Purification | Key Benefits |

|---|---|---|

| Catalyst Synthesis | Molecular-level control over material properties | Targeted removal of H2S, CO2, and chlorides |

| Membrane Growth | Uniform thin-film deposition with controlled porosity | Consistent gas flow and efficient contaminant trapping |

| Surface Engineering | Creation of chemically resistant coatings | Protection of downstream equipment from corrosion |

| Process Tuning | Optimization of temperature and pressure | High-purity synthesis gas for industrial efficiency |

Elevate Your Gas Purification Performance with KINTEK

Don't let corrosive impurities like H2S and chlorides compromise your industrial assets. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art CVD systems, alongside Muffle, Tube, and Vacuum furnaces, all fully customizable to your unique research or production needs.

Our precision-engineered systems empower you to develop the advanced catalysts and filtration membranes required for high-purity synthesis gas and superior equipment protection. Experience the KINTEK advantage in material synthesis—Contact us today to find your custom solution!

Visual Guide

References

- Shiwei Yu, Mingjie Feng. Workflow Design and Operational Analysis of a Coal‐Based Multi‐Energy Combined Supply System for Electricity, Heating, Cooling, and Gas. DOI: 10.1002/ese3.70137

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

People Also Ask

- What specific thin films can CVD furnaces prepare? Discover Versatile Films for Electronics and Coatings

- What is the temperature range for chemical vapor deposition? From 200°C to 900°C for Precise Thin Films

- What are the uses of chemical vapour deposition? Powering Modern Tech from Chips to Solar Panels

- Why is an RTP furnace used for selenium thin films? Master Precision Recovery with Rapid Thermal Processing

- What are the disadvantages of chemical Vapour deposition method? High Costs, Complexity & Material Limits

- What is the difference between CVD and PVD deposition? Choose the Right Coating Technology

- What materials are used in CVD? A Guide to High-Performance Thin Films for Your Lab

- What are the main types of thin film deposition processes? Compare PVD vs. CVD for Your Lab