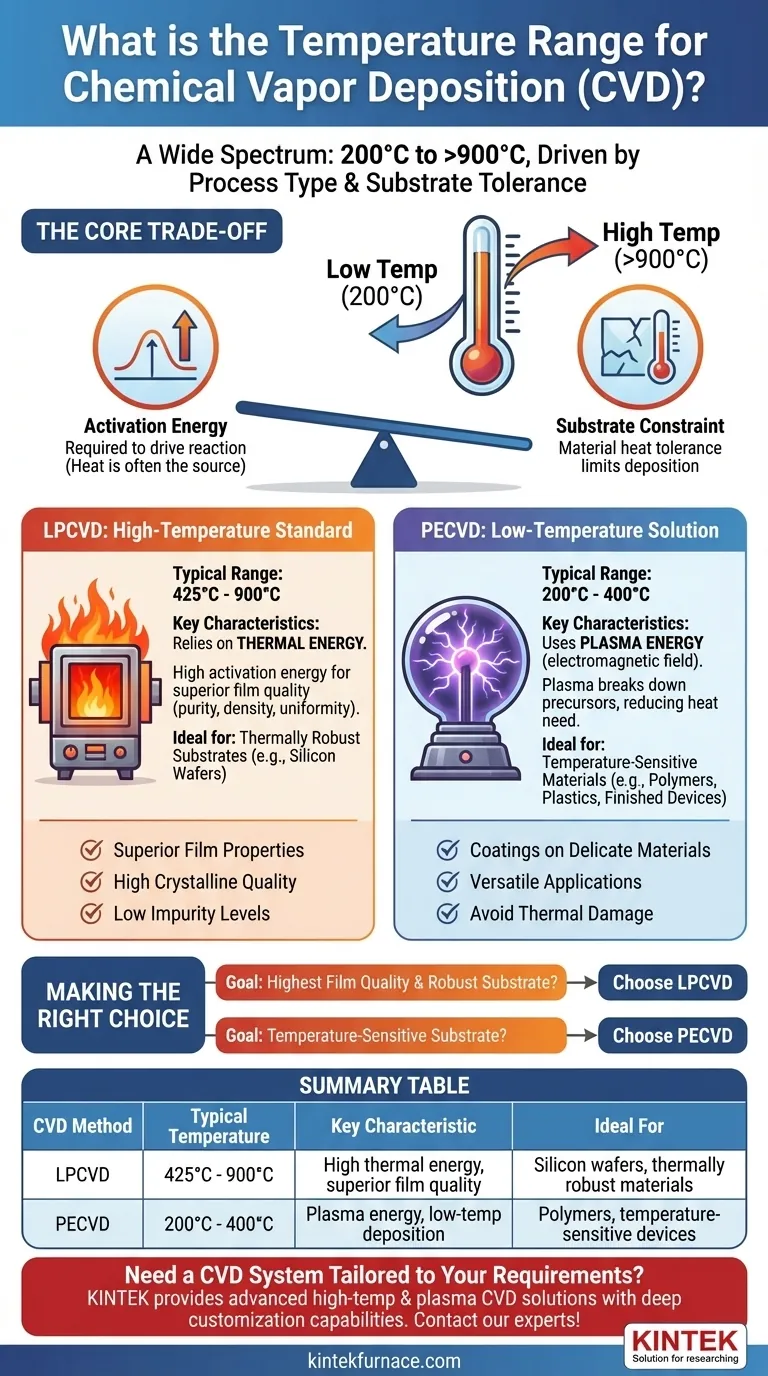

The temperature range for Chemical Vapor Deposition (CVD) is exceptionally wide, spanning from as low as 200°C to over 900°C. This variation is not arbitrary; it is determined by the specific type of CVD process being employed. The fundamental difference lies in how the process supplies the necessary energy to drive the chemical reactions that form the thin film.

The core issue is managing the energy required for the deposition reaction against the heat tolerance of the material you are coating (the substrate). Different CVD methods have been developed specifically to navigate this trade-off, creating a spectrum of processes defined by their operating temperatures.

Why Temperature Governs the CVD Process

Chemical Vapor Deposition is fundamentally a process where precursor gases react near a heated surface to form a solid, high-purity thin film. Temperature is the primary lever that controls this transformation.

The Role of Activation Energy

For the precursor gases to break apart and deposit as a film, they must overcome an energy barrier known as activation energy. In many traditional CVD methods, thermal energy—heat—is the sole source of this energy. Insufficient heat means the reaction will not proceed effectively, if at all.

The Constraint of the Substrate

The object being coated, known as the substrate, has its own thermal limits. While a silicon wafer can tolerate very high heat, a finished integrated circuit, a polymer, or other temperature-sensitive materials cannot. Applying too much heat will damage or destroy the substrate, making the deposition useless.

Comparing CVD Techniques by Temperature

The different "flavors" of CVD are largely defined by how they solve the energy-versus-substrate problem. The two most common thermal and plasma-based methods illustrate this perfectly.

Low-Pressure CVD (LPCVD): The High-Temperature Standard

LPCVD operates at high temperatures, typically between 425°C and 900°C. It relies almost exclusively on thermal energy to drive the deposition reaction.

The high heat provides ample activation energy, resulting in films with excellent purity, density, and uniformity. This makes it ideal for applications in microelectronics where film quality is paramount and the silicon substrates can withstand the heat.

Plasma-Enhanced CVD (PECVD): The Low-Temperature Solution

PECVD operates at significantly lower temperatures, ranging from 200°C to 400°C. This is its defining advantage.

Instead of relying solely on heat, PECVD uses an electromagnetic field (typically radio frequency) to generate a plasma. This plasma, a state of ionized gas, is highly energetic and effectively breaks down the precursor gases. The plasma provides the activation energy, dramatically reducing the need for high substrate temperatures.

Understanding the Trade-offs

Choosing a CVD method is an exercise in balancing competing priorities. The process temperature is central to this decision.

The Benefit of High Temperature

Processes like LPCVD use high heat to achieve superior film properties. The resulting films are often more crystalline, have lower impurity levels (like incorporated hydrogen), and exhibit better electrical characteristics. The trade-off is the limited range of substrates that can survive the process.

The Benefit of Low Temperature

The clear advantage of PECVD is its ability to deposit films on materials that cannot withstand high heat. This opens up applications for coating polymers, plastics, and fully fabricated electronic devices without causing thermal damage. The potential trade-off can sometimes be in film quality, which may be less dense or have different chemical properties than a high-temperature equivalent.

Making the Right Choice for Your Goal

Your application's specific requirements for film quality and substrate compatibility will dictate the correct process.

- If your primary focus is the highest possible film quality on a thermally robust substrate (like bare silicon): LPCVD is often the superior choice because its purely thermal process yields exceptional material properties.

- If your primary focus is depositing a film on a temperature-sensitive material (like a polymer or a finished device): PECVD is the necessary choice, as its low-temperature operation prevents substrate damage.

By understanding how temperature dictates the capabilities and limitations of each CVD method, you can select the precise tool needed to achieve your material deposition goals.

Summary Table:

| CVD Method | Typical Temperature Range | Key Characteristic | Ideal For |

|---|---|---|---|

| LPCVD | 425°C - 900°C | High thermal energy for superior film quality | Thermally robust substrates (e.g., silicon wafers) |

| PECVD | 200°C - 400°C | Plasma energy enables low-temperature deposition | Temperature-sensitive materials (e.g., polymers, finished devices) |

Need a CVD System Tailored to Your Specific Temperature and Substrate Requirements?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including our specialized CVD and PECVD systems. Whether you require the high-temperature precision of LPCVD for superior film quality or the low-temperature capability of PECVD for delicate substrates, our strong deep customization capabilities ensure your system is built to meet your unique experimental needs precisely.

Contact our experts today to discuss how we can optimize a CVD solution for your laboratory.

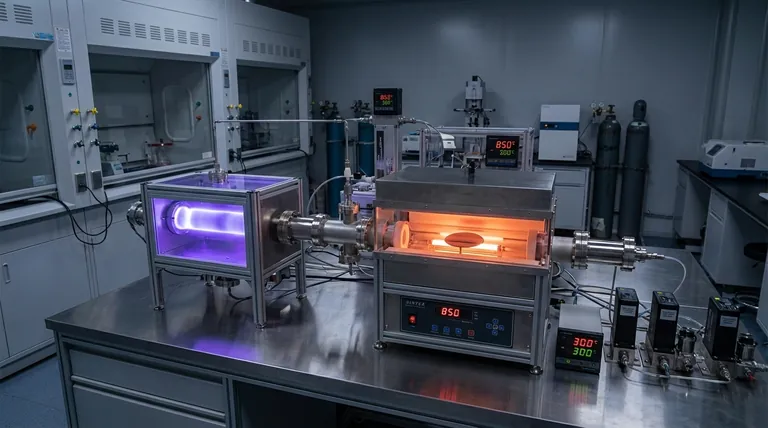

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What environments does a PECVD system provide for silicon nanowires? Optimize Growth with Precise Thermal Control

- What methods are used to analyze and characterize graphene samples? Unlock Key Techniques for Accurate Material Analysis

- What is the function of a PECVD system in the passivation of UMG silicon solar cells? Enhance Efficiency with Hydrogen

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK

- How does a PECVD system contribute to (n)poly-Si layers? High-Throughput In-Situ Doping Explained