A Chemical Vapor Deposition (CVD) system guarantees the quality of carbon layers by strictly regulating the methane gas flow rate, the reaction temperature, and the specific duration of the growth phase. By maintaining a reaction environment at approximately 1000 °C, the system ensures the controlled breakdown of methane, allowing carbon atoms to settle precisely onto the alumina template.

The core success of this method lies in its ability to achieve conformal deposition—a uniform coating roughly the thickness of a single graphene layer. This precision preserves the high specific surface area of the alumina nanoparticles while creating a robust, structurally precise carbon framework.

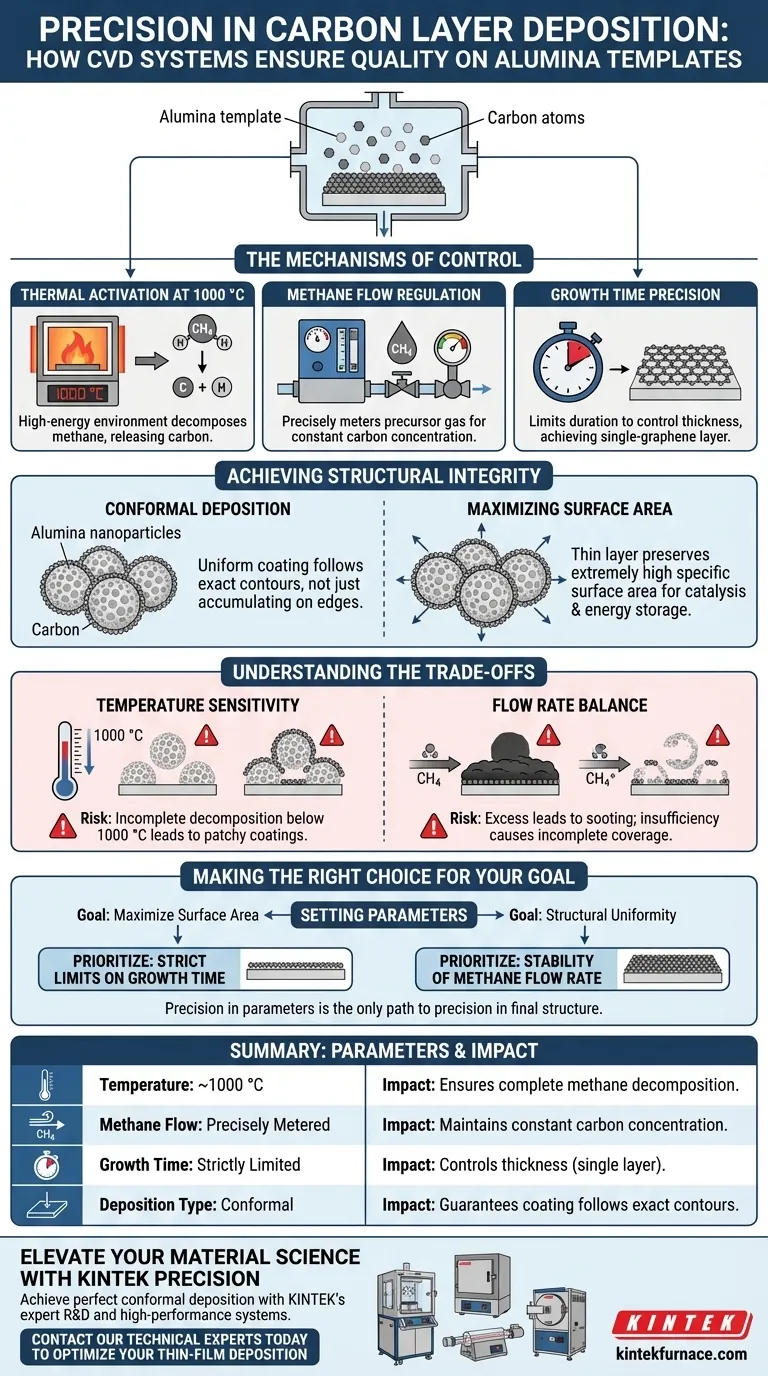

The Mechanisms of Control

To transform raw alumina nanoparticles into high-performance carbon-coated materials, the CVD system orchestrates three specific variables.

Thermal Activation at 1000 °C

The system creates a high-energy environment by heating the reaction chamber to approximately 1000 °C.

This specific temperature is critical for effectively decomposing the methane gas. It provides the energy required to break chemical bonds and release carbon atoms for deposition.

Methane Flow Regulation

Methane acts as the precursor, or the source material, for the carbon coating.

The system precisely meters the flow rate of this gas. This control ensures that the concentration of carbon available for deposition remains constant throughout the process.

Growth Time Precision

The duration of the process dictates the final thickness of the material.

By limiting the growth time, the system prevents the buildup of excess carbon. This restriction is vital for achieving a layer that is only as thick as a single sheet of graphene.

Achieving Structural Integrity

The result of these controlled parameters is not just a coating, but a precise architectural modification of the template.

Conformal Deposition

The CVD process allows carbon atoms to follow the exact contours of the alumina nanoparticles.

This "conformal" nature means the coating is uniform across the entire geometry, rather than accumulating only on the top or outer edges.

Maximizing Surface Area

Because the coating is kept to the thickness of a single graphene layer, the bulk volume of the material does not increase significantly.

This preserves the extremely high specific surface area of the original nanoparticles, which is often the most valuable property for applications like catalysis or energy storage.

Understanding the Trade-offs

While CVD offers exceptional precision, it relies heavily on the stability of the operating environment.

Temperature Sensitivity

The process is highly sensitive to thermal fluctuations.

If the temperature drops significantly below 1000 °C, the methane may not decompose fully, leading to patchy or low-quality coatings.

Flow Rate Balance

There is a delicate balance required in gas flow rates.

Excessive flow can lead to "sooting" or thick, amorphous carbon layers that ruin the desired single-layer structure. Conversely, insufficient flow may result in incomplete coverage of the alumina template.

Making the Right Choice for Your Goal

When configuring a CVD process for carbon coating alumina, your parameter settings define your outcome.

- If your primary focus is maximizing surface area: Prioritize strict limits on growth time to ensure the layer never exceeds the thickness of a single graphene sheet.

- If your primary focus is structural uniformity: Focus on the stability of the methane flow rate to ensure every nanometer of the template receives equal carbon distribution.

Precision in the process parameters is the only path to precision in the final material structure.

Summary Table:

| Parameter | Targeted Value | Impact on Quality |

|---|---|---|

| Temperature | ~1000 °C | Ensures complete methane decomposition and carbon release. |

| Methane Flow | Precisely Metered | Maintains constant carbon concentration for uniform deposition. |

| Growth Time | Strictly Limited | Controls thickness to achieve a single graphene-like layer. |

| Deposition Type | Conformal | Guarantees coating follows the exact contours of nanoparticles. |

Elevate Your Material Science with KINTEK Precision

Achieving perfect conformal deposition requires a CVD system that offers unwavering stability and control. Backed by expert R&D and manufacturing, KINTEK provides high-performance CVD systems, Muffle, Tube, and Vacuum furnaces designed to meet the rigorous demands of carbon-layer engineering.

Whether you are scaling up production or conducting pioneering research on alumina templates, our customizable lab high-temperature systems ensure the thermal and gas-flow precision your project deserves.

Ready to optimize your thin-film deposition? Contact our technical experts today to find the perfect solution for your unique laboratory needs.

Visual Guide

References

- Mitesh Ganpat Mapari, Tae Young Kim. Edge‐Free Graphene‐Derived Mesoporous Carbon for High‐Voltage Supercapacitors. DOI: 10.1002/sstr.202500265

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is the basic principle of Chemical Vapor Deposition (CVD)? Unlock High-Purity Thin-Film Synthesis

- What is the specific function of a thermal evaporation system in IPSLS growth? Precision Precursor Deposition

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab

- What is the primary function of CVT equipment in growth of CrSb crystals? High-Purity Single Crystal Growth

- What forms of energy can be applied in CVD to initiate chemical reactions? Explore Heat, Plasma, and Light for Optimal Thin Films

- When is CVD the preferred choice? Achieve Superior Thin Films for Complex Applications

- What limitations does CVD have in coating large surfaces? Overcome Scale Challenges with Custom Solutions

- What are the advantages of using CVD furnaces for film deposition? Achieve High-Quality, Uniform Thin Films