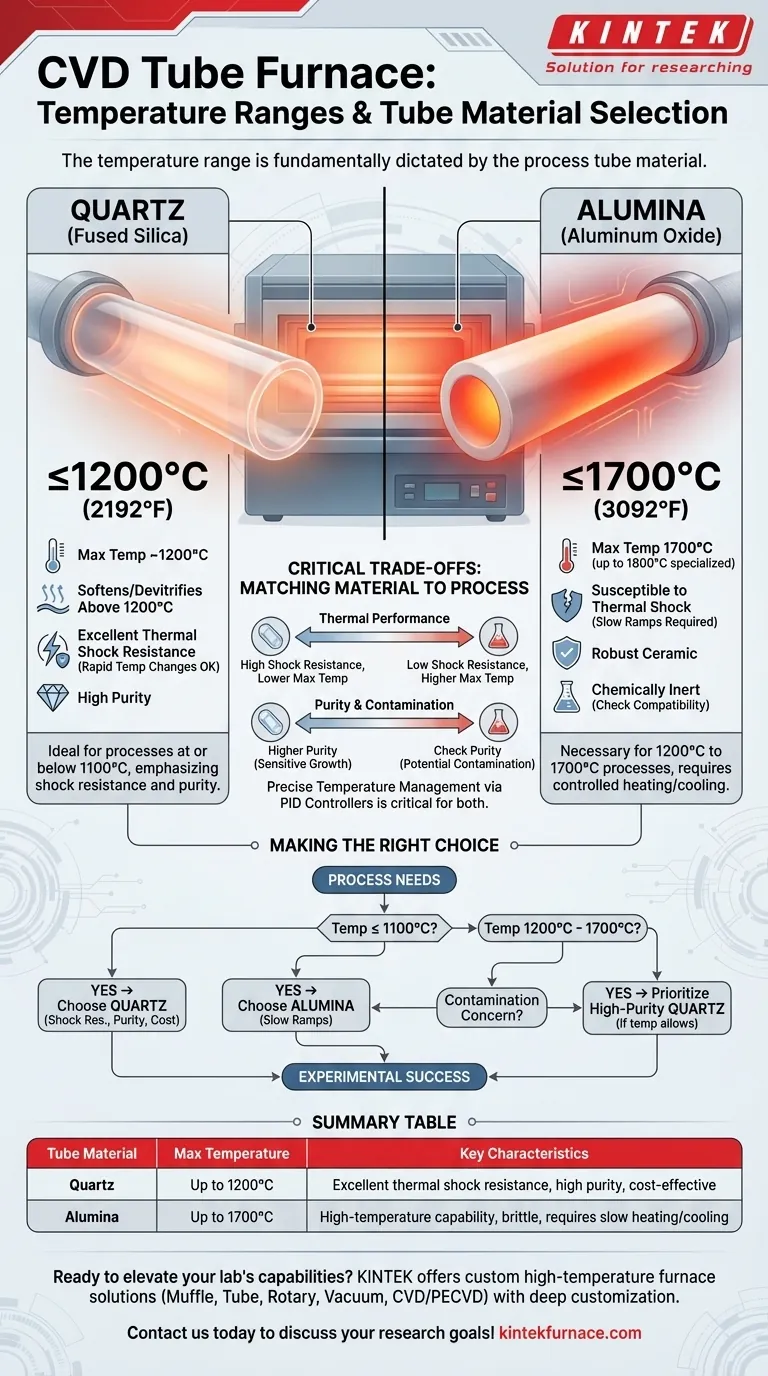

The temperature range of a CVD tube furnace is fundamentally dictated by the material of the process tube itself. For most standard applications, quartz tubes are used for processes up to approximately 1200°C (2192°F). When higher temperatures are required, alumina tubes are employed, allowing the furnace to safely reach up to 1700°C (3092°F), with some specialized systems pushing toward 1800°C.

Your choice of tube material is not just a temperature decision; it's a critical trade-off between thermal performance, chemical inertness, and resistance to thermal shock. Matching the material to your specific process parameters is essential for both experimental success and operational safety.

A Breakdown of Common Tube Materials

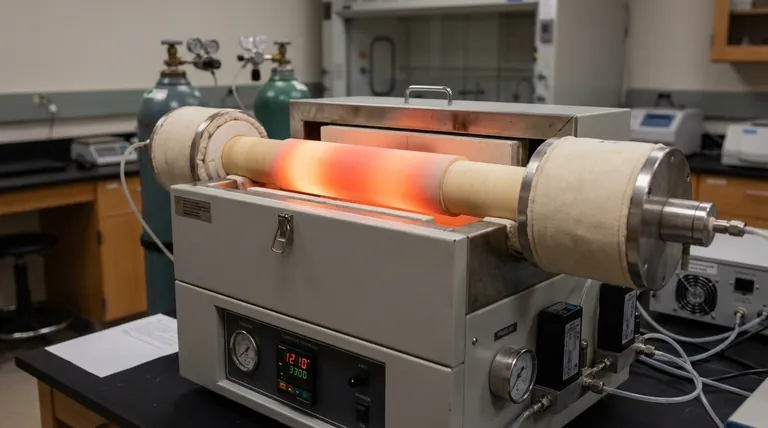

The process tube is the heart of the furnace, creating the controlled environment where chemical vapor deposition occurs. Its ability to withstand heat and chemical attack is paramount.

Quartz (Fused Silica): The Standard for ≤1200°C

Quartz is the most common material for a wide range of CVD applications. It offers an excellent combination of thermal properties and high purity.

Its upper working temperature is around 1200°C. Above this point, the material begins to soften (devitrify), compromising its structural integrity and potentially causing the tube to fail under vacuum or pressure.

One of the key advantages of quartz is its excellent thermal shock resistance. It can withstand rapid temperature changes much better than ceramic alternatives, which simplifies heating and cooling protocols.

Alumina (Aluminum Oxide): The Choice for High-Temperature Processes

For processes that require temperatures beyond the limits of quartz, alumina is the go-to material. It is a robust ceramic capable of stable operation.

Alumina tubes enable furnace temperatures up to 1700°C, and in some high-temperature furnace models, can be pushed to 1800°C.

This high-temperature capability makes alumina essential for growing certain materials, such as specific oxides or nitrides, that require more thermal energy.

Understanding the Trade-offs

Selecting a tube is not as simple as picking the one with the highest temperature rating. You must consider the practical implications for your specific experiment.

Thermal Shock and Brittleness

The primary drawback of alumina is its susceptibility to thermal shock. Unlike quartz, alumina tubes can crack if heated or cooled too quickly. This necessitates slower, more carefully programmed temperature ramps, which can increase overall process time.

Chemical Compatibility and Purity

The tube material must be inert and not react with your precursor gases or byproducts. While both materials are relatively inert, quartz is generally of higher purity, making it preferable for sensitive electronic or optical material growth where contamination is a major concern.

Precise Temperature Management

Regardless of the tube material, achieving a stable and accurate temperature is critical. Modern tube furnaces use advanced PID (Proportional-Integral-Derivative) controllers to precisely regulate power to the heating elements. This ensures the system reaches the setpoint temperature and holds it with minimal deviation, which is vital for process repeatability.

Making the Right Choice for Your Process

Your decision should be based on a clear understanding of your experimental needs and the inherent properties of each material.

- If your process runs at or below 1100°C: Quartz is almost always the superior choice due to its excellent thermal shock resistance, high purity, and lower cost.

- If your process requires temperatures between 1200°C and 1700°C: Alumina is your necessary solution, but you must design your process with slow, controlled heating and cooling cycles.

- If you are concerned about potential contamination: Prioritize a high-purity quartz tube, provided your temperature requirements allow for it.

By carefully matching the tube material to your process temperature and chemical environment, you ensure the integrity and success of your work.

Summary Table:

| Tube Material | Max Temperature | Key Characteristics |

|---|---|---|

| Quartz | Up to 1200°C | Excellent thermal shock resistance, high purity, cost-effective |

| Alumina | Up to 1700°C | High-temperature capability, brittle, requires slow heating/cooling |

Ready to elevate your lab's capabilities with a custom high-temperature furnace solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures precise alignment with your unique experimental needs, delivering superior performance and reliability. Contact us today to discuss how we can support your research and development goals!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics