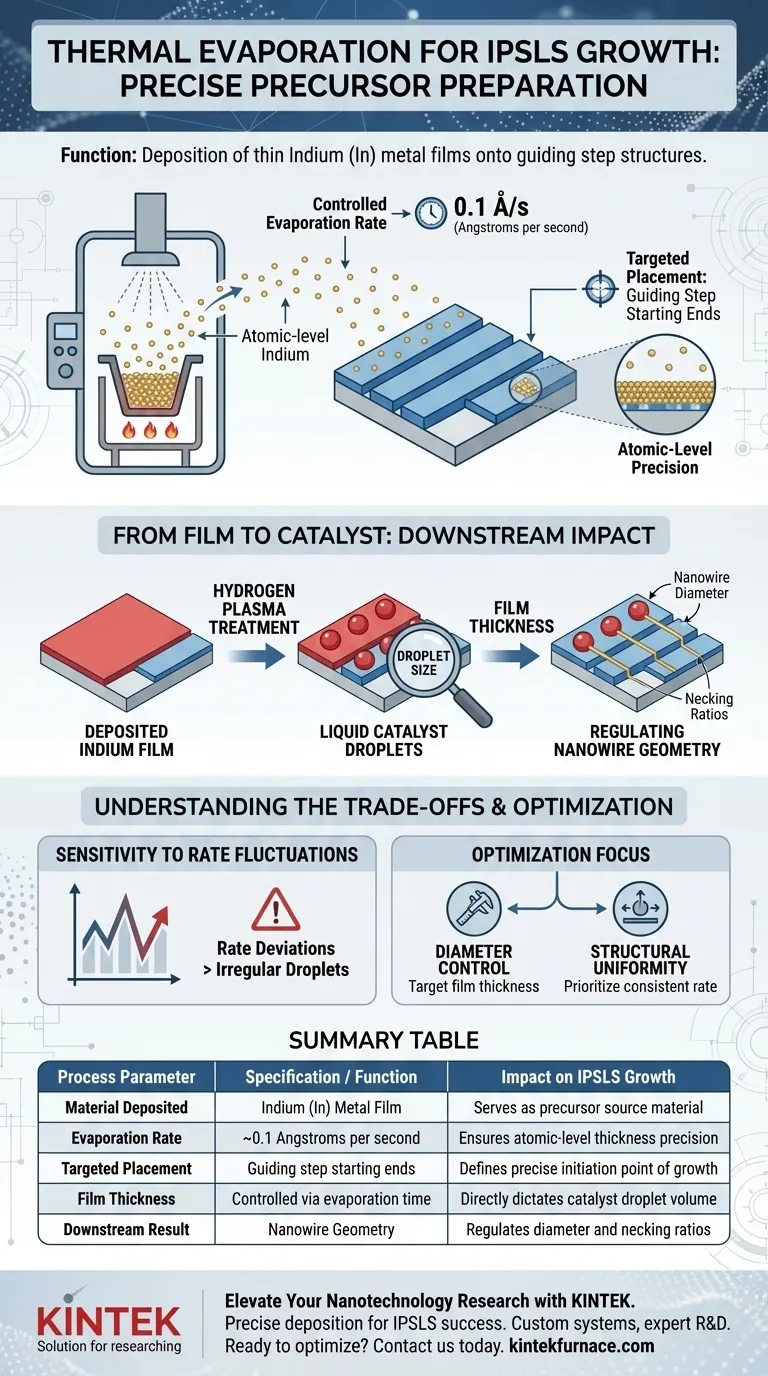

The primary function of a thermal evaporation system in this context is to deposit thin Indium (In) metal films onto the starting ends of guiding step structures. This is a high-precision process that establishes the precursor material necessary for subsequent In-Plane Solid-Liquid-Solid (IPSLS) growth.

The system does not merely coat the substrate; it acts as a precise volume controller. By strictly regulating the evaporation rate, the system defines the initial Indium film thickness, which directly dictates the size of the catalyst droplets and the resulting nanowire geometry.

The Mechanics of Precursor Deposition

Controlled Evaporation Rate

The thermal evaporation system operates by maintaining a specific, low evaporation rate of approximately 0.1 Angstroms per second.

This slow rate is critical for achieving uniformity. It allows for the deposition of the Indium film with atomic-level precision, ensuring the layer is exactly the required thickness.

Targeted Placement

The deposition is not random; it is spatially targeted at the starting ends of the guiding step structures.

This placement ensures that the Indium source material is located exactly where the growth process is intended to initiate, preventing unwanted nucleation elsewhere on the substrate.

From Film to Catalyst: The Downstream Impact

Determining Droplet Size

The physical thickness of the deposited Indium film is the primary variable that determines the volume of the catalyst.

Upon subsequent hydrogen plasma treatment, this solid film dewets and balls up. The volume of material provided by the evaporation system dictates the exact size of the liquid catalyst droplets formed during this phase.

Regulating Nanowire Geometry

There is a direct causal link between the precursor preparation and the final product structure.

The size of the catalyst droplet regulates the nanowire diameter. Furthermore, the initial film thickness is a key parameter for controlling necking ratios, defining the structural integrity and shape of the nanowire as it grows.

Understanding the Trade-offs

Sensitivity to Rate Fluctuations

The reliance on a rate of 0.1 Angstroms per second implies a high sensitivity to process variations.

If the evaporation rate fluctuates, the film thickness will deviate from the target. This deviation propagates through the process, resulting in catalyst droplets that are either too large or too small for the intended guiding structures.

The Dependency on Plasma Treatment

It is important to note that the thermal evaporation system prepares the potential for the catalyst, not the catalyst itself.

The system relies entirely on the subsequent hydrogen plasma treatment to convert the film into functional droplets. If the evaporation system deposits an irregular film, the plasma treatment will amplify these irregularities rather than correct them.

Optimizing Precursor Preparation

To ensure successful IPSLS growth, you must view the thermal evaporation step as the geometric definition phase of your experiment.

- If your primary focus is Nanowire Diameter Control: Calibrate the thermal evaporation system to deposit the exact film thickness corresponding to your target droplet volume.

- If your primary focus is Structural Uniformity: Prioritize the stability of the evaporation rate at 0.1 Angstroms per second to ensure consistent film thickness across all guiding steps.

Success in IPSLS growth begins with the rigorous control of the initial Indium deposition.

Summary Table:

| Process Parameter | Specification / Function | Impact on IPSLS Growth |

|---|---|---|

| Material Deposited | Indium (In) Metal Film | Serves as the precursor source material |

| Evaporation Rate | ~0.1 Angstroms per second | Ensures atomic-level thickness precision |

| Targeted Placement | Guiding step starting ends | Defines the precise initiation point of growth |

| Film Thickness | Controlled via evaporation time | Directly dictates catalyst droplet volume |

| Downstream Result | Nanowire Geometry | Regulates diameter and necking ratios |

Elevate Your Nanotechnology Research with KINTEK

Precise precursor deposition is the foundation of successful In-Plane Solid-Liquid-Solid (IPSLS) growth. At KINTEK, we understand that atomic-level precision is non-negotiable for your laboratory's success.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temp lab furnaces—all fully customizable to meet your unique thin-film and thermal processing needs. Whether you are aiming for perfect nanowire geometry or consistent catalyst formation, our systems provide the stability and control your research demands.

Ready to optimize your deposition process? Contact us today to speak with our technical experts about a tailored solution for your lab.

Visual Guide

References

- Lei Wu, Linwei Yu. Step-necking growth of silicon nanowire channels for high performance field effect transistors. DOI: 10.1038/s41467-025-56376-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What types of materials are most suitable for PVD and CVD? Optimize Your Thin Film Deposition Choices

- What are the applications of CVD coating? Creating Durable, Functional Surfaces for Industry

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What is the role of the gold (Au) catalyst layer in the VLS growth of ZnO nanowires? Master Precision Synthesis

- What are the advantages of TMGa in MOCVD of beta-gallium oxide? Achieve High Growth Rates and Industrial Scalability

- What is the primary function of a CVD furnace for bulk ZnS? Master Precision Reaction for Infrared Optics

- What is the high-temperature capability of specialized CVD furnaces? Achieve Up to 1950°C for Advanced Materials

- What are the structural varieties of materials deposited by CVD? Unlock Material Properties for Your Applications