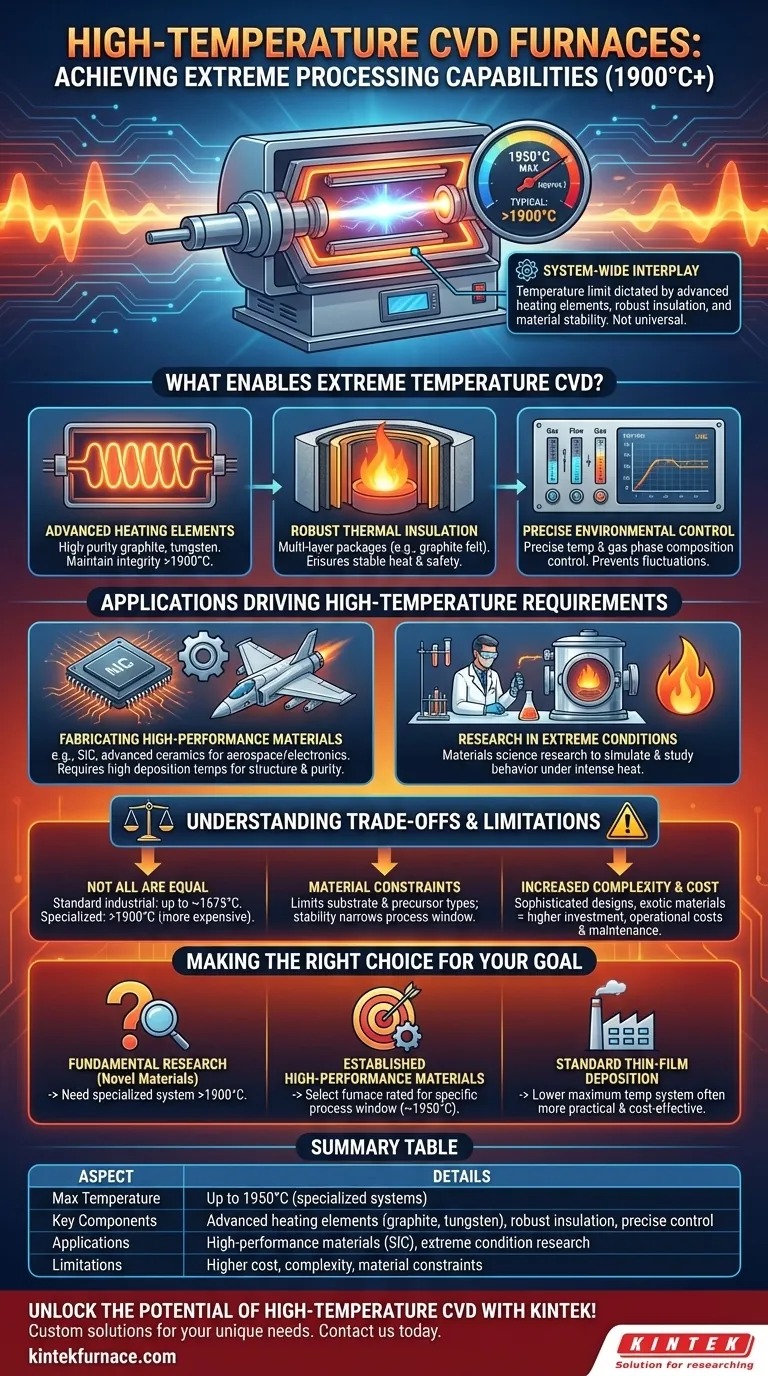

In specialized applications, Chemical Vapor Deposition (CVD) furnaces can operate at extreme temperatures, typically reaching over 1900°C. Certain highly advanced systems are designed to achieve temperatures up to approximately 1950°C, enabling the fabrication of next-generation materials under severe processing conditions.

While specialized CVD furnaces can operate above 1900°C, this capability is not universal. The true temperature limit is dictated by a system-wide interplay of advanced heating elements, robust insulation, and the chemical stability of the materials being processed.

What Enables Extreme Temperature CVD?

Achieving and maintaining temperatures near 2000°C is not a simple task. It requires a furnace designed from the ground up with specialized components and precise control systems to manage such a demanding thermal environment.

Advanced Heating Elements

Standard heating elements cannot withstand these temperatures. Specialized CVD furnaces rely on materials like high-purity graphite or tungsten, which maintain their structural integrity and heating efficiency well above 1900°C.

Robust Thermal Insulation

To maintain stable, uniform heat and protect the surrounding equipment, these furnaces use multi-layer insulation packages made from graphite felt or other advanced refractory materials. This ensures energy efficiency and operational safety.

Precise Environmental Control

High temperature is only one part of the equation. The system must also provide precise temperature control and manage a controllable gas phase composition. This prevents temperature fluctuations and ensures the precursor gases react as intended, which is critical for creating high-quality, uniform thin films.

Applications Driving High-Temperature Requirements

The need for such extreme temperatures is driven by the synthesis of materials with exceptional properties that cannot be formed under normal conditions.

Fabricating High-Performance Materials

Materials like certain advanced ceramics, silicon carbide (SiC), and other composites for aerospace or high-power electronics require extremely high deposition temperatures to achieve the desired crystalline structure and purity.

Research in Extreme Conditions

These furnaces are invaluable tools for materials science research. They allow scientists to simulate extreme environments and study how materials behave and form under conditions of intense heat and controlled pressure.

Understanding the Trade-offs and Limitations

While impressive, these high-temperature capabilities come with significant constraints that must be understood before selecting a system.

Not All CVD Furnaces Are Equal

It is critical to distinguish between standard and specialized furnaces. Many industrial CVD systems operate at lower maximum temperatures, with some reaching up to 1675°C. The ability to exceed 1900°C is a feature of highly specialized, and often more expensive, equipment.

Material and Process Constraints

The extreme heat limits the types of substrates and precursor gases that can be used. Many materials are not stable at these temperatures, which narrows the process window significantly. The choice of furnace is fundamentally dependent on the material being processed.

Increased Complexity and Cost

Furnaces capable of reaching these temperatures require more sophisticated designs, exotic materials, and advanced safety systems. This results in higher initial investment, increased operational costs, and more demanding maintenance protocols.

Making the Right Choice for Your Goal

Choosing a furnace requires matching its thermal capacity to your specific material and process goals.

- If your primary focus is fundamental research on novel materials: You will likely need a specialized system capable of reaching or exceeding 1900°C to explore synthesis under extreme conditions.

- If your primary focus is producing established high-performance materials: Select a furnace specifically rated for that material's known process window, which may require temperatures approaching 1950°C.

- If your primary focus is standard thin-film deposition: A furnace with a lower maximum temperature is often more practical, reliable, and cost-effective for your application.

Ultimately, the furnace's temperature capability is a critical tool that must be precisely aligned with your material science objectives.

Summary Table:

| Aspect | Details |

|---|---|

| Max Temperature | Up to 1950°C for specialized systems |

| Key Components | Advanced heating elements (e.g., graphite, tungsten), robust insulation (e.g., graphite felt), precise environmental control |

| Applications | Fabrication of high-performance materials (e.g., SiC, advanced ceramics), research in extreme conditions |

| Limitations | Higher cost, increased complexity, material stability constraints |

Unlock the potential of high-temperature CVD for your lab with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, tailored to your unique needs. Our deep customization ensures precise performance for materials science and industrial applications. Contact us today to discuss how our furnaces can elevate your research and production!

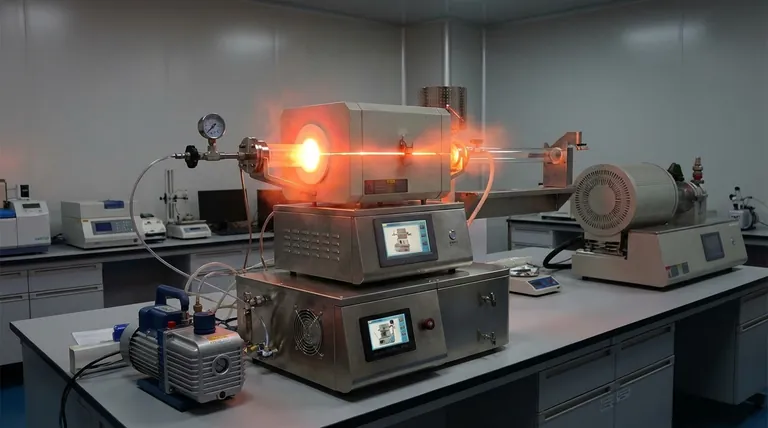

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- What future trends are expected in the development of CVD tube furnaces? Discover Smarter, More Versatile Systems