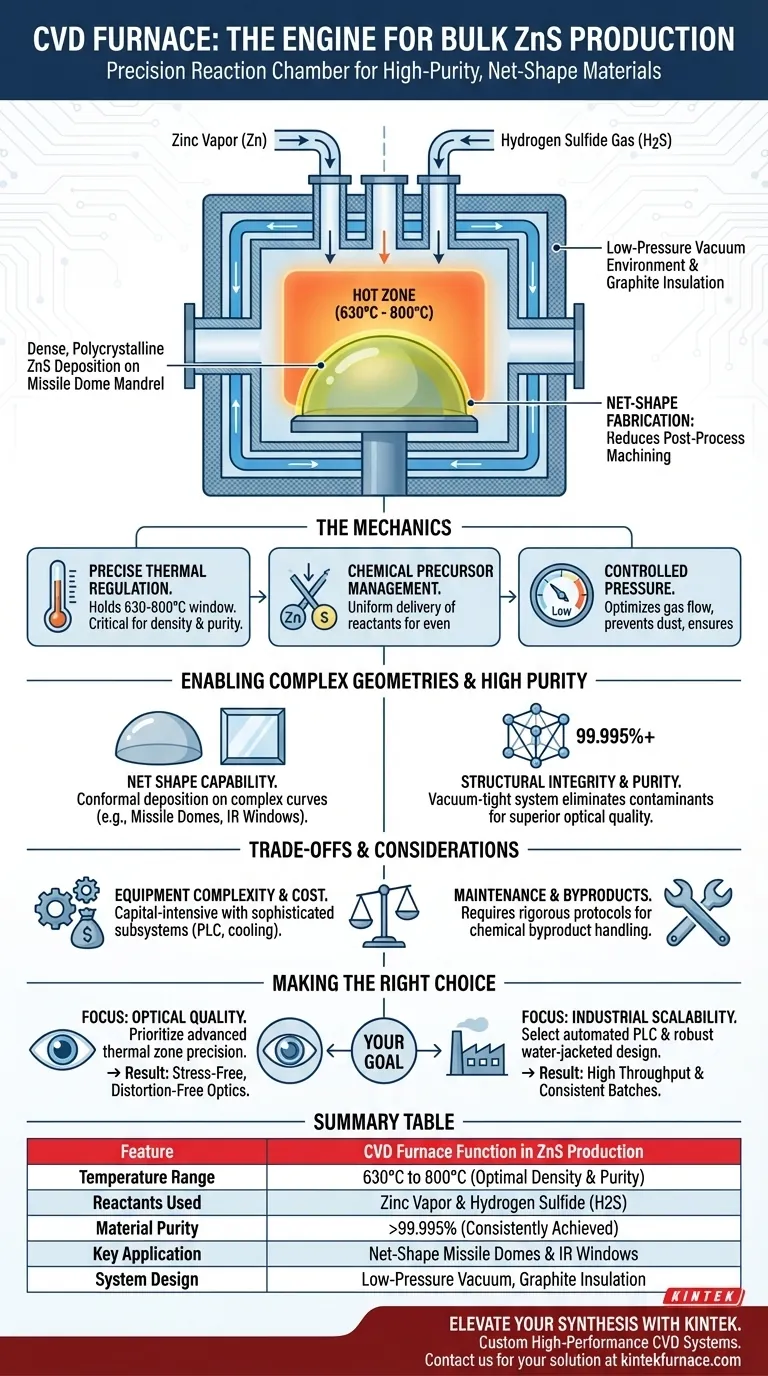

The primary function of a CVD furnace in bulk ZnS production is to act as a precision reaction chamber. Specifically, it maintains a low-pressure environment at high temperatures, typically between 630°C and 800°C, to facilitate a chemical reaction between zinc vapor and hydrogen sulfide gas. This process results in the deposition of dense, polycrystalline Zinc Sulfide (ZnS), enabling the creation of solid, bulk materials rather than just thin surface coatings.

Core Insight: Unlike standard CVD applications that focus on thin films, the furnace configuration for ZnS is designed for bulk material synthesis. It allows for the "net shape" fabrication of complex, high-purity components—such as missile domes and infrared optical windows—that require structural integrity and exceptional optical clarity.

The Mechanics of the Deposition Process

Precise Thermal Regulation

The furnace creates a "hot zone," often utilizing graphite insulation and heating elements.

For ZnS production, the system must hold a strictly controlled temperature range of 630-800°C. This specific thermal window is critical to ensure the chemical reaction occurs at a rate that promotes density and purity.

Chemical Precursor Management

The furnace is responsible for the safe and uniform delivery of reactants.

It introduces zinc vapor and hydrogen sulfide (H2S) into the chamber. The furnace design ensures these gases mix thoroughly to deposit ZnS uniformly across the substrate or mandrel.

Controlled Pressure Environment

The process operates under low pressure to optimize the mean free path of the gas molecules.

While general CVD furnaces can range from vacuum to 2 psig, ZnS production relies on low pressure to prevent gas-phase nucleation (dust formation) and ensure the material deposits solidly on the target surface.

Enabling Complex Geometries

Net Shape Capability

One of the most valuable functions of this furnace type is the ability to produce "net shape" components.

Because the gas reactants are highly conformal, the furnace can deposit material onto irregularly shaped mandrels. This allows for the direct fabrication of complex curves, such as missile domes, reducing the need for extensive post-process machining.

Structural Integrity and Purity

The furnace environment is designed to eliminate contaminants.

By maintaining a sealed, vacuum-tight environment (often utilizing water-cooled stainless steel walls), the system produces materials with purity levels often exceeding 99.995%. This results in fine-grained, mechanically hard materials suitable for demanding optical applications.

Understanding the Trade-offs

Equipment Complexity and Cost

CVD furnaces capable of bulk production are capital-intensive.

They require sophisticated subsystems, including liquid-cooled power supplies, PLC automation, and pneumatic valve headers. High durability is required to offset the initial investment, making them best suited for high-value industrial applications.

Maintenance and Byproducts

While often self-cleaning regarding the chamber walls, the handling of chemical byproducts presents a challenge.

The reaction between Zinc and H2S produces byproducts that must be managed carefully. The system requires rigorous maintenance protocols to handle the exhaust and scrubbers, ensuring safety and environmental compliance.

Making the Right Choice for Your Goal

To maximize the value of a CVD furnace for ZnS production, align your equipment selection with your specific output requirements.

- If your primary focus is Optical Quality: Prioritize a furnace with advanced thermal zone precision to prevent gradients that could cause stress or optical distortion in the window or dome.

- If your primary focus is Industrial Scalability: Select a system featuring automated PLC process controls and a robust, water-jacketed design to ensure high throughput and consistent batch-to-batch repeatability.

Success in bulk ZnS production relies not just on the chemistry, but on the furnace's ability to maintain an unwavering, contaminant-free environment over long deposition cycles.

Summary Table:

| Feature | CVD Furnace Function in ZnS Production |

|---|---|

| Temperature Range | 630°C to 800°C for optimal density and purity |

| Reactants Used | Zinc vapor and Hydrogen Sulfide (H2S) gas |

| Material Purity | Consistently achieves levels exceeding 99.995% |

| Key Application | Net-shape fabrication of missile domes and IR windows |

| System Design | Low-pressure vacuum environment with graphite insulation |

Elevate Your Advanced Material Synthesis with KINTEK

Unlock the full potential of your lab with high-performance CVD systems designed for the most demanding applications. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique thermal and chemical processing needs. Whether you are producing high-purity ZnS optics or pioneering new thin-film technologies, our equipment provides the unwavering precision and durability your research demands.

Ready to optimize your production? Contact KINTEK today to discuss your custom furnace solution with our specialists!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role do high-purity quartz boats play during the chemical vapor deposition (CVD) of MoS2? Optimize Thin-Film Growth

- Why is it necessary to adjust sample position in deposition chambers for large-scale tantalum-carbon composites?

- How does a CVD machine work? Master the Technology for High-Quality Thin Film Deposition

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- What is Laser Chemical Vapor Deposition (LCVD)? Precision Micro-Scale 3D Printing for Thin Films

- What is the function of a customized spray pyrolysis chamber? Optimize ZnSe and PbSe Thin Film Synthesis

- How does the gas control system in a CVD tube furnace enhance its functionality? Achieve Precise Thin Film Deposition

- What are the industrial applications of materials deposited by CVD? Unlock High-Performance Thin Films for Your Industry