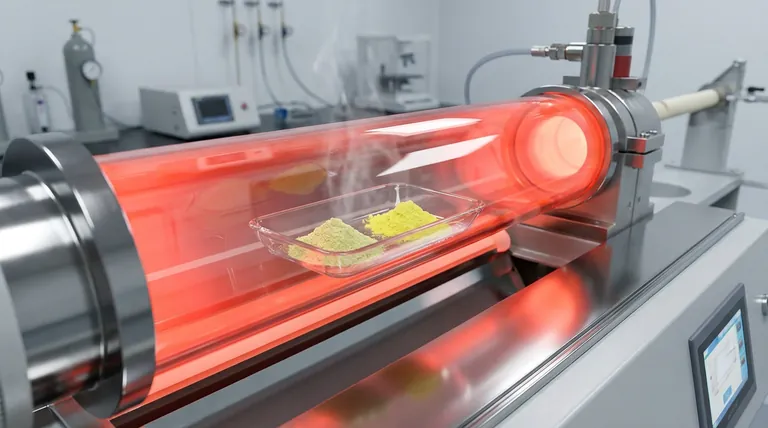

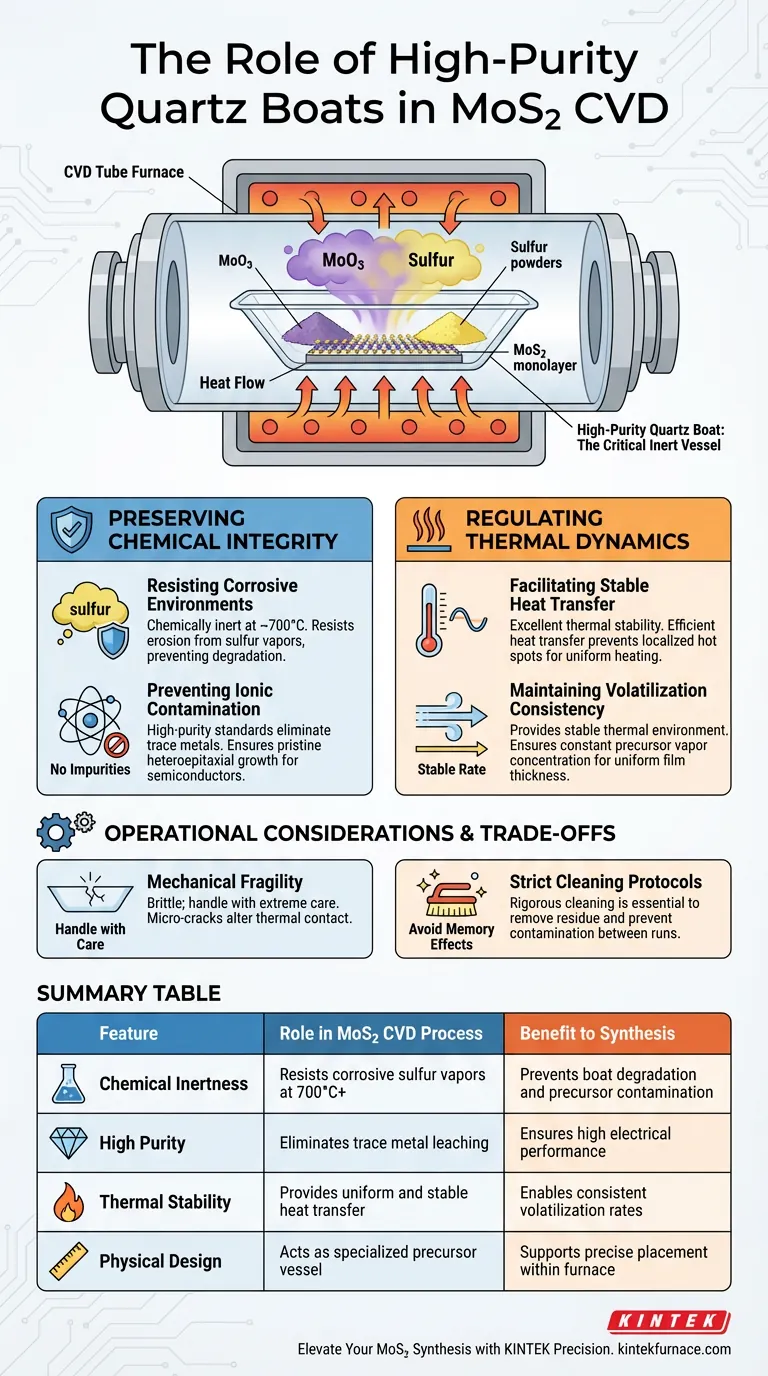

High-purity quartz boats serve as the critical, inert vessels used to hold the molybdenum trioxide (MoO3) and sulfur precursors during Chemical Vapor Deposition (CVD). They act as the primary interface between the furnace’s heating elements and the raw materials, facilitating the controlled evaporation necessary for synthesizing molybdenum disulfide (MoS2).

By acting as a chemically neutral thermal conductor, high-purity quartz boats prevent impurities from leaching into the reaction environment while ensuring the stable heat transfer required for a consistent precursor volatilization rate.

Preserving Chemical Integrity

Resisting Corrosive Environments

The CVD process for MoS2 creates a harsh environment filled with corrosive sulfur vapors at high temperatures (typically around 700°C).

High-purity quartz is chemically inert, meaning it resists erosion from these sulfur vapors. This ensures the boat does not degrade or react with the precursors during the long synthesis process.

Preventing Ionic Contamination

For semiconductor applications, even trace amounts of metal impurities can ruin the electrical performance of the MoS2 interface.

Quartz boats are manufactured to extremely high purity standards. This prevents the introduction of external impurities into the reaction chamber, ensuring the heteroepitaxial growth remains pristine.

Regulating Thermal Dynamics

Facilitating Stable Heat Transfer

The quality of the MoS2 film depends heavily on the temperature stability of the precursors.

Quartz boats possess excellent thermal stability, allowing them to transfer heat from the furnace to the raw powders (MoO3 and Sulfur) efficiently. This ensures the powders reach the target temperature without localized hot spots.

Maintaining Volatilization Consistency

To grow a uniform monolayer of MoS2, the concentration of precursor vapor in the chamber must remain constant.

By providing a stable thermal environment, the quartz boat ensures a consistent volatilization rate. This prevents surges or drops in vapor pressure that would otherwise lead to uneven film thickness or incomplete crystal growth.

Operational Considerations and Trade-offs

Mechanical Fragility

While thermally robust, quartz is mechanically brittle.

Boats must be handled with extreme care during loading and unloading. Micro-cracks or chips can alter the thermal contact with the furnace tube, potentially skewing the volatilization rate of the precursors.

Strict Cleaning Protocols

Because the boat is in direct contact with the source materials, it retains residue after every run.

You must implement rigorous cleaning cycles. Any leftover contaminants from a previous run will volatize in the next cycle, introducing memory effects that compromise the purity of subsequent batches.

Optimizing Your CVD Setup

To maximize the effectiveness of your MoS2 synthesis, select your equipment based on your specific experimental goals:

- If your primary focus is electronic-grade purity: Ensure you source certified high-purity quartz boats to eliminate any risk of metallic ion contamination degrading the semiconductor interface.

- If your primary focus is reproducibility: Standardize the specific geometry and placement of the boat within the heating zone to guarantee identical volatilization rates across multiple runs.

The quartz boat is not just a container; it is a thermal regulator that dictates the consistency of your precursor supply.

Summary Table:

| Feature | Role in MoS2 CVD Process | Benefit to Synthesis |

|---|---|---|

| Chemical Inertness | Resists corrosive sulfur vapors at 700°C+ | Prevents boat degradation and precursor contamination |

| High Purity | Eliminates trace metal leaching | Ensures high electrical performance of semiconductor interfaces |

| Thermal Stability | Provides uniform and stable heat transfer | Enables consistent volatilization rates for uniform film growth |

| Physical Design | Acts as a specialized precursor vessel | Supports precise placement within furnace heating zones |

Elevate Your MoS2 Synthesis with KINTEK Precision

Don't let impurities or thermal instability compromise your semiconductor research. KINTEK provides the high-performance tools necessary for successful Chemical Vapor Deposition. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-purity quartzware—all customizable to your unique lab requirements.

Ready to achieve pristine MoS2 monolayer growth? Contact our technical experts today to discover how our high-temperature furnace solutions can bring unmatched consistency and purity to your materials science applications.

Visual Guide

References

- Effects of Reaction Temperature and Catalyst Type on Fluid Catalytic Cracking (FCC) of Crude Oil Feeds: A Microactivity Test Unit Study. DOI: 10.64589/juri/207996

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key characteristics and benefits of CVD coatings? Achieve Superior Surface Protection for Complex Parts

- What are the benefits of using a CVD furnace? Achieve Atomic-Level Control for Superior Thin Films

- What are the disadvantages of traditional CVD for 2D materials? Overcome High-Temp and Transfer Issues

- What is the function of a horizontal hot-wall quartz tube CVD system? Expert Insights on Superlattice Fabrication

- What is a CVD reactor chemical vapor deposition? Build High-Performance Thin Films Atom by Atom

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- What is the high-temperature capability of specialized CVD furnaces? Achieve Up to 1950°C for Advanced Materials

- What are the advantages of these CVD systems compared to conventional CVD? Unlock Lower Temperatures and Faster Processing