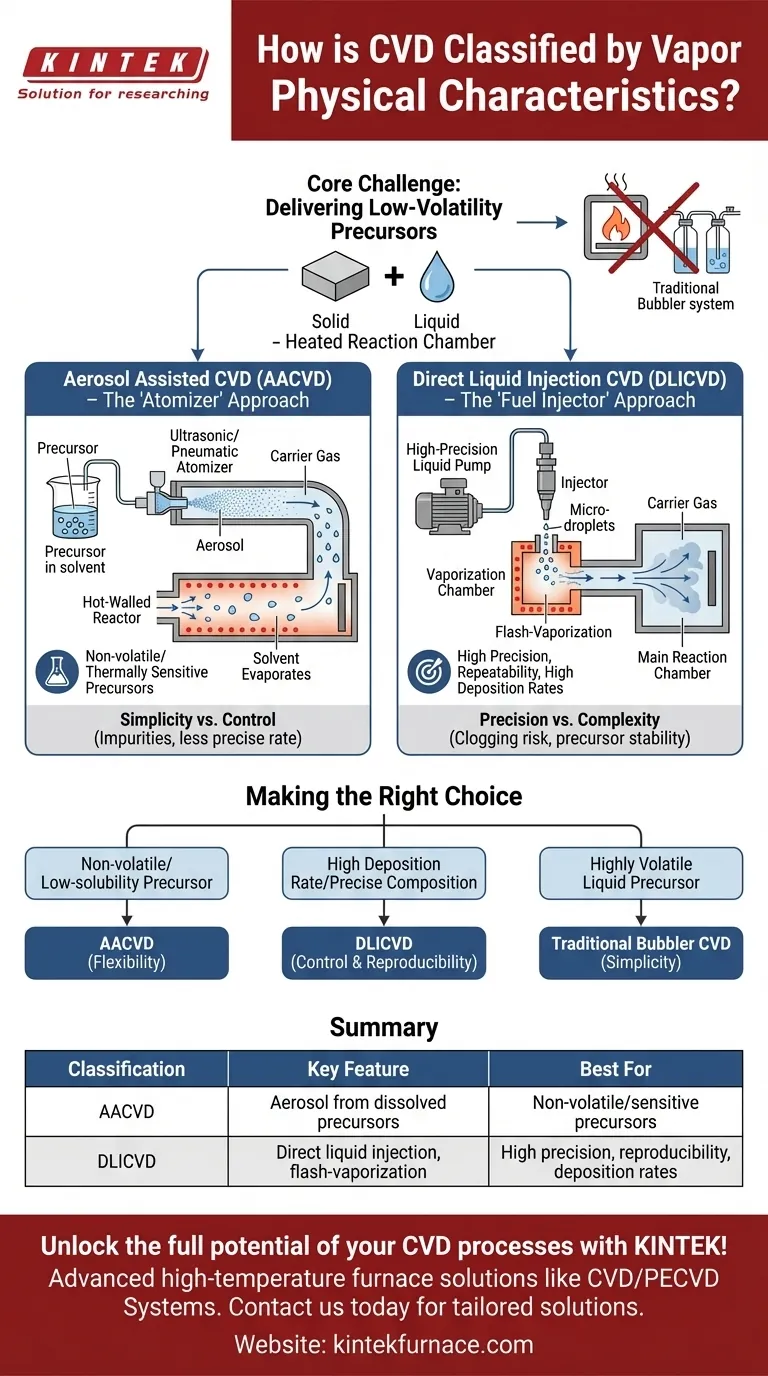

In material science, the physical characteristics of the vapor are a critical factor in classifying Chemical Vapor Deposition (CVD) processes. The two primary classifications based on vapor delivery are Aerosol Assisted CVD (AACVD) and Direct Liquid Injection CVD (DLICVD). These methods are specifically designed to handle precursors that are not easily turned into a gas, such as liquids or dissolved solids.

The core distinction is not just about the vapor itself, but how that vapor is generated and transported into the reaction chamber. Choosing between AACVD and DLICVD is a strategic decision based on your precursor's properties and your desired film characteristics, such as growth rate and purity.

The Core Challenge: Delivering Precursors

The fundamental goal of any CVD process is to transport chemical precursors in a gaseous state to a heated substrate where they can react and form a solid film. The method of delivery is a key differentiator.

Standard CVD and Its Limitations

Traditional CVD methods work best with precursors that are already gases at room temperature or are liquids with high vapor pressure. These can be easily transported into the reaction chamber using a simple bubbler and a carrier gas.

This approach fails when the desired precursor is a solid, has very low volatility (doesn't evaporate easily), or is thermally unstable and decomposes if heated to create vapor.

The Need for Specialized Vapor Delivery

To overcome these limitations, specialized techniques were developed to generate a vapor from difficult liquid or solid precursors. This is where the classification based on vapor characteristics becomes essential.

These methods give scientists the flexibility to use a much wider range of chemical precursors, enabling the creation of novel and complex materials.

A Closer Look at Vapor Delivery Methods

AACVD and DLICVD represent two distinct engineering solutions to the problem of delivering low-volatility precursors.

Aerosol Assisted CVD (AACVD): The "Atomizer" Approach

In AACVD, the precursor is first dissolved in a suitable solvent. This liquid solution is then atomized—typically using an ultrasonic transducer or a pneumatic nebulizer—to create a fine mist of tiny droplets, known as an aerosol.

A carrier gas then transports this aerosol into the hot-walled reactor. As the droplets travel through the hot zone, the solvent evaporates, and the precursor vaporizes just before reaching the substrate.

This method's primary advantage is its ability to handle non-volatile or thermally sensitive precursors that cannot be vaporized by direct heating.

Direct Liquid Injection CVD (DLICVD): The "Fuel Injector" Approach

DLICVD takes a more direct route. It uses a high-precision liquid pump and injector, much like a fuel injector in a car engine, to deliver controlled micro-droplets of the liquid precursor directly into a heated vaporization chamber.

This flash-vaporization process is extremely rapid and efficient. The resulting vapor is then immediately swept into the main reaction chamber by a carrier gas.

DLICVD is valued for its high precision, repeatability, and ability to achieve high deposition rates.

Understanding the Trade-offs

Neither method is universally superior; the choice involves a clear set of engineering trade-offs.

AACVD: Simplicity vs. Control

AACVD systems can be relatively simple to construct. Their key weakness, however, is the use of a solvent, which can sometimes become incorporated into the final film as an impurity. Controlling the exact precursor delivery rate can also be less precise than with DLICVD.

DLICVD: Precision vs. Complexity

DLICVD offers exceptional control over precursor flow, leading to highly reproducible film growth. The main downsides are the increased complexity and cost of the injection system and the risk of the injector clogging over time. This method also requires precursors that can be vaporized cleanly without premature decomposition.

Deposition Rate Considerations

While DLICVD enables high growth rates for a CVD process, it is important to contextualize this. As a whole, CVD processes often have slower deposition rates compared to line-of-sight techniques like Physical Vapor Deposition (PVD), which can be a factor for applications requiring rapid, thick coatings.

Making the Right Choice for Your Application

Your choice of vapor delivery method directly impacts your process capabilities and the quality of your final material.

- If your primary focus is working with non-volatile or low-solubility precursors: AACVD provides the necessary flexibility to get these materials into the vapor phase.

- If your primary focus is achieving high deposition rates and precise film composition: DLICVD offers superior control and reproducibility, provided your precursor is thermally stable.

- If your primary focus is simplicity with a highly volatile liquid precursor: A traditional bubbler-based CVD system may be the most straightforward and effective solution.

Ultimately, understanding how to generate and transport your precursor vapor is fundamental to mastering the CVD process for your specific material goals.

Summary Table:

| Classification | Key Feature | Best For |

|---|---|---|

| AACVD | Uses aerosol from dissolved precursors | Non-volatile or thermally sensitive precursors |

| DLICVD | Uses direct liquid injection for flash-vaporization | High precision, reproducibility, and deposition rates |

Unlock the full potential of your CVD processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions like CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior film quality and efficiency. Contact us today to discuss how our tailored solutions can elevate your material science research and production!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- Why is the temperature control system important in MPCVD equipment? Ensure Precise Diamond Growth and Process Stability

- What are some applications of MPCVD? Unlock High-Purity Diamond for Advanced Engineering

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- Why is maintaining gas pipelines important in MPCVD equipment? Ensure Purity and Safety in Crystal Growth