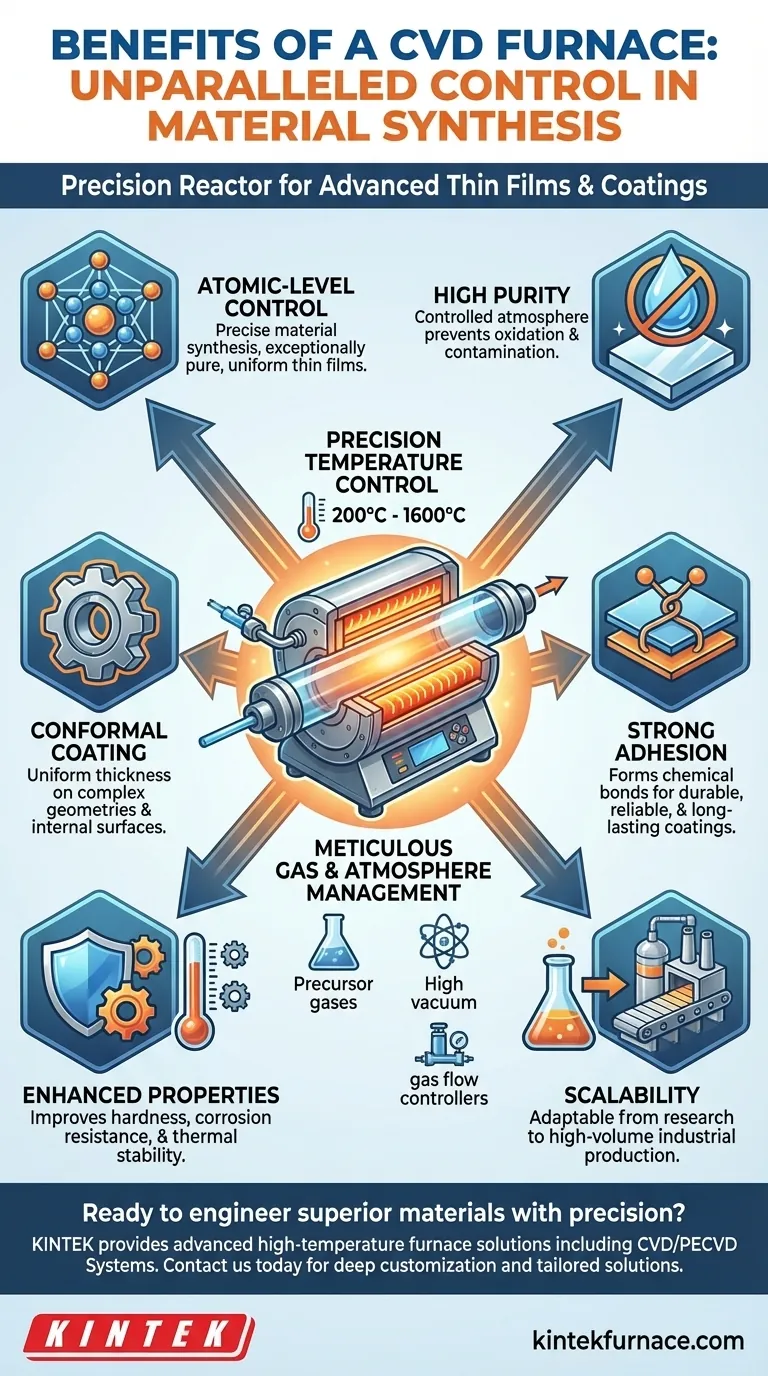

In essence, a CVD furnace offers unparalleled control over material synthesis at the atomic level. Its primary benefits stem from its ability to create exceptionally pure, uniform, and strongly bonded thin films and coatings. This process allows for the engineering of materials with enhanced properties—like hardness, corrosion resistance, and thermal stability—on a wide variety of substrates, making it scalable from small-scale research to high-volume industrial production.

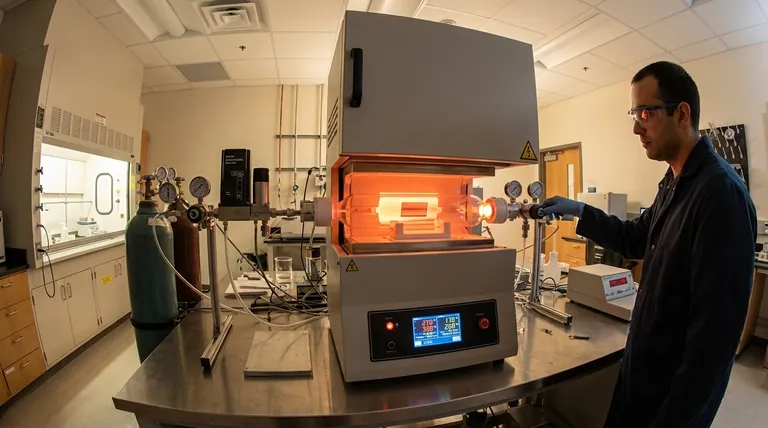

A Chemical Vapor Deposition (CVD) furnace is more than a high-temperature oven; it is a precision reactor. Its true value lies in enabling a controlled chemical reaction that deposits materials atom-by-atom, resulting in high-performance films that are often unattainable with other methods.

The Foundation of Control: How a CVD Furnace Works

The benefits of a CVD furnace are a direct result of its core design, which provides meticulous control over the chemical deposition environment. It is not just about heat; it is about managing every variable of a chemical reaction.

Precision Temperature Control

A key feature of a CVD furnace is its ability to create a highly uniform and stable temperature zone, with capabilities often ranging from 200°C to over 1600°C.

This uniform heating is critical because the CVD process relies on chemical reactions that are highly sensitive to temperature. Even small variations can alter the deposition rate and film properties, leading to inconsistencies.

Meticulous Gas and Atmosphere Management

CVD works by introducing precise amounts of precursor gases into the furnace chamber. These gases react at or near the hot substrate surface to form the desired material.

Gas flow controllers manage the exact recipe of precursors, while the system's atmosphere is tightly controlled. Operations can run under high vacuum, at atmospheric pressure, or in a low-pressure environment.

This control is what ensures high purity. By removing unwanted molecules like oxygen and water vapor in a vacuum, the furnace prevents oxidation and contamination, ensuring the deposited film consists only of the desired elements.

Versatile Chamber Design

CVD furnaces come in various configurations, most commonly as tube furnaces or batch systems. This flexibility allows the process to be adapted to different needs.

Tube furnaces are excellent for research, continuous processing, and coating uniform substrates. Different tube materials like quartz or alumina can be selected based on temperature and chemical compatibility.

Batch furnaces are designed to process many parts at once, making them suitable for industrial-scale production while still offering precise control over the heating and cooling cycles for each load.

Translating Control into Tangible Benefits

The precise control over temperature, gas chemistry, and pressure translates directly into superior material outcomes that solve specific engineering challenges.

Unmatched Purity and Composition

Because the process occurs in a controlled atmosphere using high-purity precursor gases, the resulting films are exceptionally pure.

The high-temperature chemical reactions are selective, depositing only the intended material. This results in coatings with minimal defects and a precisely controlled chemical composition, which is vital for applications in semiconductors and optics.

Superior Coating Uniformity (Conformality)

Unlike line-of-sight deposition methods (like sputtering or evaporation), the precursor gases in a CVD process can flow around and into complex geometries.

This results in a highly conformal coating, meaning the film has a uniform thickness across all surfaces of a three-dimensional object, including inside sharp corners, trenches, and holes.

Excellent Adhesion and Durability

The CVD process doesn't just lay a material on top of a substrate; it forms a chemical bond between the film and the surface.

By optimizing the deposition conditions, this bond becomes extremely strong. The resulting adhesion significantly improves the durability, reliability, and lifespan of the coated part.

Engineered Material Properties

CVD is not used to create just one type of material. It is a versatile platform for depositing a vast range of metals, ceramics, and polymers.

This allows engineers to intentionally enhance a substrate's properties. A common use is applying a hard ceramic coating (like titanium nitride) to a metal tool to increase its wear resistance, or depositing a silicon dioxide film on a wafer to act as an electrical insulator.

Understanding the Trade-offs and Considerations

While powerful, CVD is not a universal solution. Its advantages come with complexities that must be understood to make an informed decision.

High Temperature and Substrate Limits

The high temperatures required for many CVD processes can damage or warp temperature-sensitive substrates, such as polymers or certain low-melting-point metals. This is a fundamental limitation.

Process Complexity and Expertise

Developing a stable and repeatable CVD recipe is a complex task. It requires significant expertise to balance the variables of temperature, pressure, gas flow rates, and chemistry to achieve the desired film properties. This is not a "plug-and-play" technology.

Precursor Chemistry and Safety

The precursor gases used in CVD can be toxic, flammable, corrosive, or pyrophoric (igniting on contact with air). A CVD system requires robust safety infrastructure, including gas cabinets, detectors, and exhaust abatement systems to handle these hazardous materials safely.

Making the Right Choice for Your Application

Choosing a deposition method requires aligning the process capabilities with your primary goal.

- If your primary focus is ultimate purity and film quality: CVD is often the superior choice, as the controlled chemical reaction minimizes contaminants and allows for precise structural engineering.

- If you are coating complex 3D shapes or internal surfaces: The conformal nature of CVD provides uniform coverage that line-of-sight processes cannot match.

- If you are working with temperature-sensitive substrates: You must carefully consider lower-temperature CVD variants (like Plasma-Enhanced CVD) or explore alternative deposition methods entirely.

- If your priority is cost-effective coating on simple shapes: Weigh the performance gains of CVD against the lower cost and complexity of methods like electroplating or Physical Vapor Deposition (PVD).

By understanding its fundamental principles of control, you can leverage the CVD process to engineer materials with properties tailored to your specific challenge.

Summary Table:

| Benefit | Description |

|---|---|

| Atomic-Level Control | Enables precise material synthesis with uniform, strongly bonded thin films. |

| High Purity | Controlled atmosphere prevents contamination, ensuring pure coatings. |

| Conformal Coating | Uniform thickness on complex 3D shapes, including internal surfaces. |

| Strong Adhesion | Forms chemical bonds for durable, long-lasting coatings. |

| Enhanced Properties | Improves hardness, corrosion resistance, and thermal stability of substrates. |

| Scalability | Suitable from research to high-volume industrial production. |

Ready to engineer superior materials with precision? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our product line, featuring Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and drive innovation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition