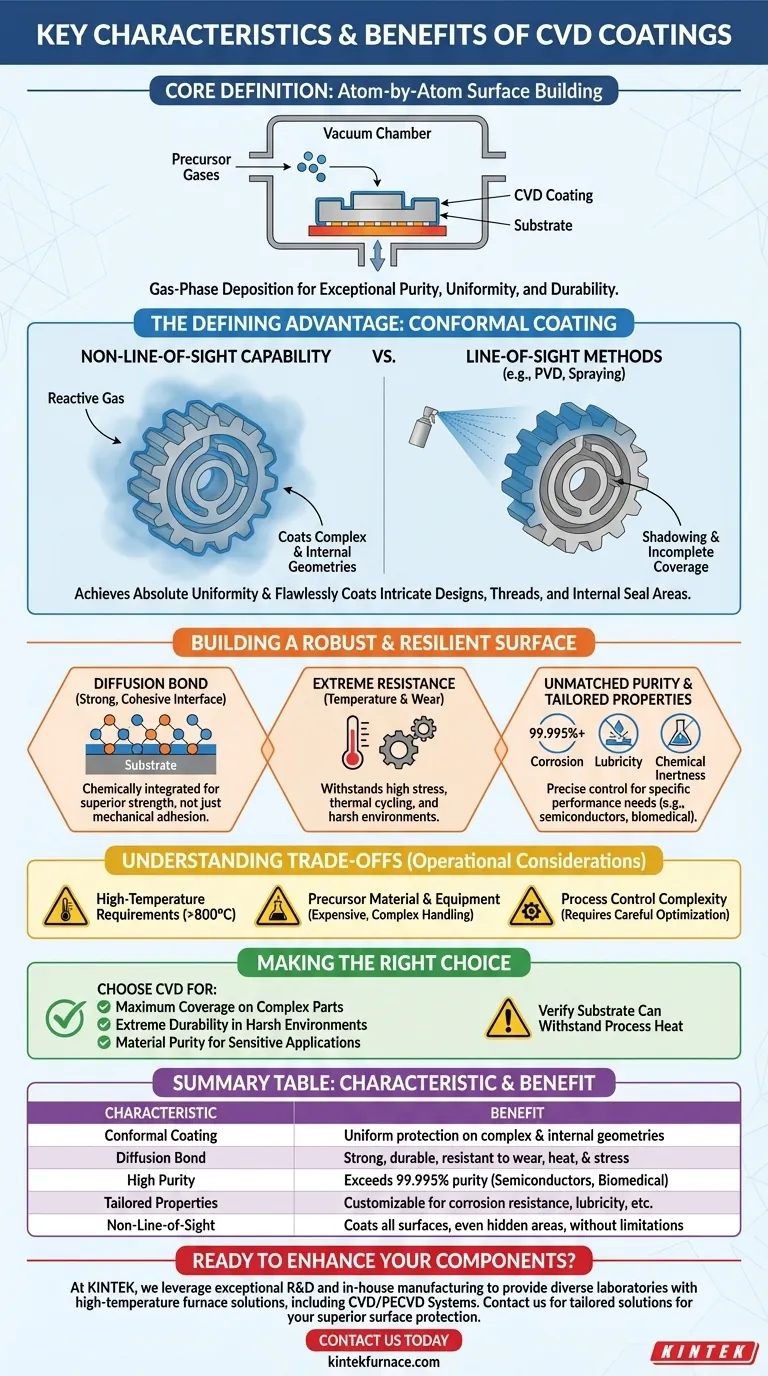

At its core, Chemical Vapor Deposition (CVD) is a process of building a high-performance surface atom-by-atom. Unlike painting or plating, CVD uses precursor gases in a vacuum chamber that react and decompose on a heated substrate, forming an exceptionally pure, uniform, and durable solid film. This method is renowned for creating coatings that are perfectly conformal, incredibly strong, and tailored for extreme performance.

The fundamental advantage of CVD is not just the quality of the coating, but its ability to be applied anywhere. Because it uses a gas, it bypasses the "line-of-sight" limitations of other methods, allowing for the complete and uniform protection of even the most complex internal and external geometries.

The Defining Advantage: Conformal Coating

The most significant characteristic of CVD is its ability to deposit a perfectly uniform layer of material over a component, regardless of its shape. This is a direct result of its gas-phase deposition mechanism.

How CVD Transcends Line-of-Sight

In processes like spraying or Physical Vapor Deposition (PVD), the coating material travels in a straight line from the source to the substrate. This means any surface not in the direct path—like the inside of a tube or the underside of a feature—remains uncoated.

CVD solves this by filling the entire chamber with a reactive gas. The gas molecules move freely around the part, reaching every nook, cranny, and internal channel before depositing the coating.

Achieving Absolute Uniformity

Because the deposition occurs wherever the gas can reach, the resulting coating has a highly consistent thickness across the entire part. This uniformity is critical for precision components where even minor variations can impact performance.

Coating Internal and Complex Features

This non-line-of-sight capability makes CVD indispensable for parts with intricate designs. It can flawlessly coat internal seal areas, fine threads, and complex lattice structures, ensuring no part of the substrate is left exposed and vulnerable to corrosion or wear.

Building a Robust and Resilient Surface

A CVD coating is not merely sitting on top of the substrate; it becomes chemically integrated with it, creating a surface with exceptional durability and stability.

The Power of a Diffusion Bond

The high temperatures used in many CVD processes facilitate a diffusion bond between the coating and the substrate. Atoms from the coating and the base material intermingle at the interface, forming an incredibly strong, cohesive bond that is far superior to a purely mechanical one.

Extreme Temperature and Wear Resistance

This strong bond ensures the coating remains intact even under high mechanical stress, extreme temperature variations, and thermal cycling. The materials deposited are often inherently hard and stable, providing excellent wear resistance and protection in harsh operating environments.

Unmatched Purity and Tailored Properties

CVD is capable of producing films with extremely high purity, often exceeding 99.995%. This is critical for industries like semiconductors and biomedical, where impurities can cause catastrophic failure.

Furthermore, the precursor gas chemistry can be precisely controlled to tailor the coating's properties. A surface can be engineered for chemical inertness, corrosion resistance, lubricity, or other specific performance requirements.

Understanding the Trade-offs

No process is without its limitations. True expertise requires understanding not just the benefits of CVD, but also its operational considerations.

High-Temperature Requirements

Traditional CVD processes often require very high temperatures (often >800°C) to trigger the necessary chemical reactions. This can limit the types of substrate materials that can be coated, as the process heat could warp, anneal, or otherwise damage the underlying part.

Precursor Material and Equipment

The gases used as precursors in CVD can be expensive, toxic, or corrosive, requiring specialized handling procedures and equipment. This can increase the overall cost and complexity of the operation compared to simpler coating methods.

Process Control Complexity

While CVD offers precise control, achieving it requires careful management of numerous variables, including temperature, pressure, gas flow rates, and chamber chemistry. Optimizing a process for a new part or coating can be a complex undertaking.

Making the Right Choice for Your Goal

Selecting a coating technology depends entirely on your primary engineering challenge. CVD is not always the answer, but it is often the best solution for specific, demanding problems.

- If your primary focus is maximum coverage on complex parts: CVD is the superior choice due to its non-line-of-sight deposition, ensuring complete and uniform protection.

- If your primary focus is extreme durability in harsh environments: The strong, diffusion-bonded nature of CVD coatings provides exceptional resilience against heat, stress, and wear.

- If your primary focus is material purity for sensitive applications: CVD delivers exceptionally pure films, making it a standard in the semiconductor and biomedical fields.

- If your primary focus is coating a temperature-sensitive material: You must verify the substrate can withstand the process heat or investigate specialized low-temperature CVD variants.

By understanding its gas-phase nature, you can leverage CVD to engineer surfaces that were previously impossible to create or protect.

Summary Table:

| Characteristic | Benefit |

|---|---|

| Conformal Coating | Uniform protection on complex geometries, including internal features |

| Diffusion Bond | Strong, durable bond resistant to wear, heat, and stress |

| High Purity | Exceeds 99.995% purity, ideal for semiconductors and biomedical uses |

| Tailored Properties | Customizable for corrosion resistance, lubricity, and more |

| Non-Line-of-Sight | Coats all surfaces, even hidden areas, without limitations |

Ready to enhance your components with advanced CVD coatings? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior surface protection. Contact us today to discuss how our tailored solutions can benefit your projects!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition