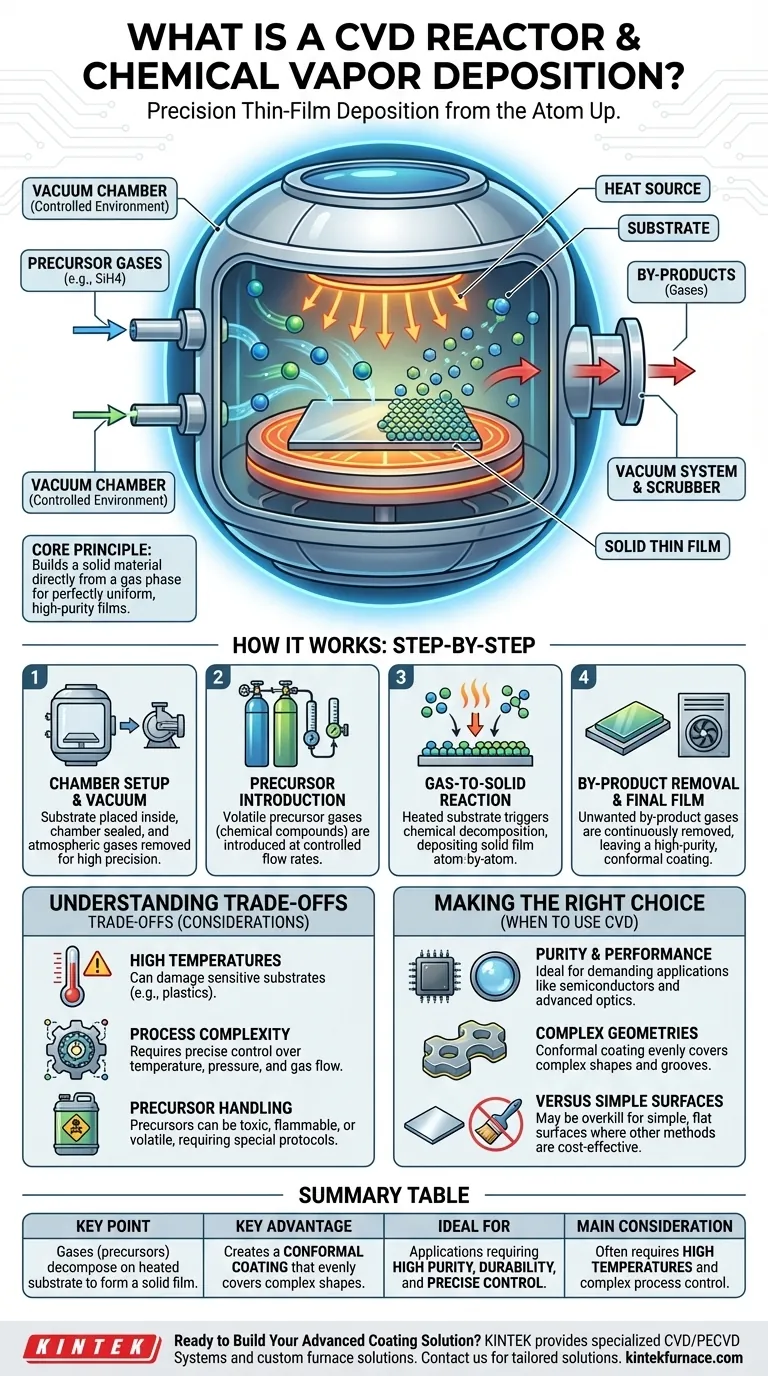

At its core, a Chemical Vapor Deposition (CVD) reactor is a highly controlled chamber used to apply an ultra-thin, high-performance solid film onto a surface. The process works by introducing specific reactive gases (precursors) into the vacuum chamber, where they decompose and deposit onto a heated object (substrate) atom-by-atom. This method creates exceptionally pure and durable coatings with precise control over thickness and composition.

The fundamental principle of CVD is not to apply a liquid coating, but to build a solid material directly from a gas phase. This allows for the creation of perfectly uniform, high-purity films on even the most complex surfaces, making it a cornerstone technology in fields like semiconductor manufacturing.

How a CVD Reactor Works: A Step-by-Step Breakdown

To understand CVD, it's best to break the process down into its essential components and stages. The entire operation takes place within the highly controlled environment of the CVD reactor.

The Reaction Chamber: A Controlled Environment

The process begins by placing the object to be coated, known as the substrate, inside the reaction chamber. The chamber is then sealed and a vacuum is created, removing atmospheric gases.

This vacuum environment is critical because it ensures that only the intended reactive gases are present, preventing contamination and allowing the process to occur with high precision.

The Precursors: Gaseous Building Blocks

Next, one or more volatile precursor gases are introduced into the chamber at a precisely controlled flow rate. These gases are chemical compounds selected specifically because they contain the atoms needed for the final coating.

For example, to deposit a film of silicon, a precursor gas like silane (SiH4) might be used.

The Reaction: From Gas to Solid

The substrate within the chamber is heated to a specific, elevated temperature. This heat provides the energy needed to trigger a chemical reaction.

The precursor gases decompose on or near the hot substrate surface. The desired solid material from the gas then deposits onto the substrate, forming a solid thin film.

The By-products and Final Film

The chemical reaction also creates volatile by-products, which are unwanted gases. These are continuously removed from the chamber by the gas flow system.

The result is a high-purity, dense, and exceptionally uniform film that is chemically bonded to the substrate surface. Because the deposition happens from a gas phase, the coating is conformal, meaning it evenly covers all exposed areas, including intricate grooves and complex geometries.

Understanding the Trade-offs

While powerful, the CVD process involves specific operational considerations and limitations that are important to understand.

High Temperature Requirements

The most common method, thermal CVD, relies on high temperatures to drive the chemical reaction. These elevated temperatures can damage or alter certain substrates, such as plastics or low-melting-point metals, limiting the types of materials that can be coated.

Process Complexity

A CVD system is a sophisticated piece of equipment. Achieving a high-quality, repeatable film requires precise control over multiple variables simultaneously, including temperature, pressure, and gas flow rates. This complexity can translate to higher equipment and operational costs.

Precursor and By-product Handling

The precursor gases used in CVD can be volatile, toxic, or flammable, requiring specialized storage and handling protocols. Likewise, the gaseous by-products must be safely managed and treated before they can be vented.

Making the Right Choice for Your Goal

CVD is a specialized process chosen for its unique capabilities. Your decision to use it should be based on the specific requirements of your final product.

- If your primary focus is material purity and performance: CVD is an exceptional choice for producing high-quality films for demanding applications like semiconductors and advanced optics.

- If your primary focus is coating a complex or intricate part: CVD's ability to create a perfectly conformal coating makes it superior to many line-of-sight deposition methods.

- If your primary focus is cost-effective coating of a simple, flat surface: You may find that the high temperatures and complexity of CVD are unnecessary, and other deposition methods could be more suitable.

Ultimately, Chemical Vapor Deposition empowers engineers and scientists to construct materials from the atom up, enabling the creation of components with precisely tailored properties.

Summary Table:

| Aspect | Key Point |

|---|---|

| Process | Gases (precursors) decompose on a heated substrate to form a solid film. |

| Key Advantage | Creates a conformal coating that evenly covers complex shapes. |

| Ideal For | Applications requiring high purity, durability, and precise control (e.g., semiconductors). |

| Main Consideration | Often requires high temperatures and precise control of process parameters. |

Ready to Build Your Advanced Coating Solution?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including specialized CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements for thin-film deposition.

Contact us today to discuss how we can help you achieve superior material performance with a tailored CVD reactor solution.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings