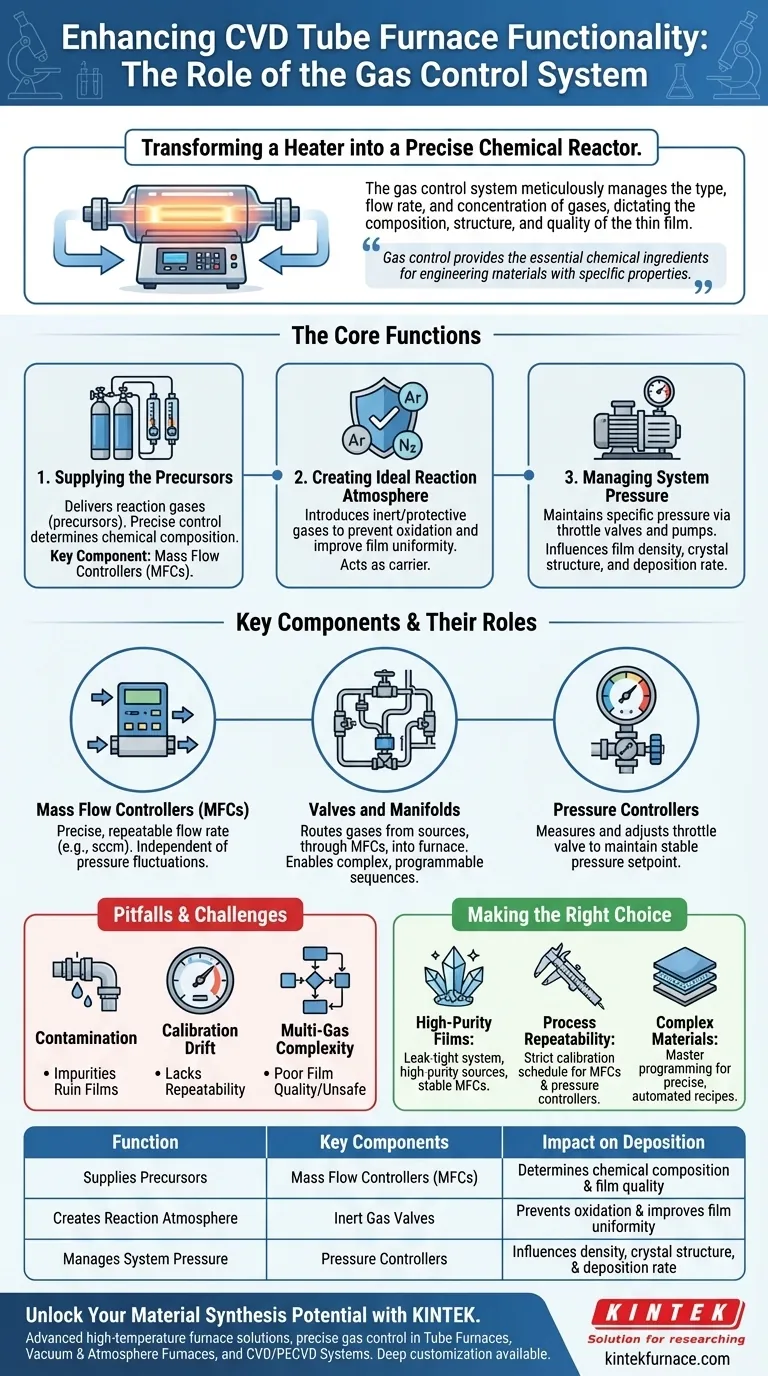

Fundamentally, the gas control system enhances a Chemical Vapor Deposition (CVD) tube furnace by transforming it from a simple heater into a precise chemical reactor. It meticulously manages the type, flow rate, and concentration of various gases, which directly dictates the composition, structure, and quality of the thin film being created.

A CVD furnace's heating element creates the necessary energy, but the gas control system provides the essential chemical ingredients. Mastering this system is the key to moving from simply heating a substrate to engineering a material with specific, repeatable properties at the atomic level.

The Core Functions of Gas Control

The gas system is not an accessory; it is central to the deposition process. Its functionality can be broken down into three primary roles that work in concert.

Supplying the Precursors

The most basic function is to deliver the reaction gases, or precursors, into the furnace tube. These are the molecules that will break down and deposit onto the substrate to form the thin film.

Precise control over the flow rate of each precursor, managed by Mass Flow Controllers, determines the chemical composition of the final material.

Creating the Ideal Reaction Atmosphere

Most CVD processes cannot occur in open air. The gas control system introduces inert or protective gases, such as argon or nitrogen.

These gases serve two purposes: they prevent unwanted chemical reactions like oxidation, and they act as a carrier to transport the precursor gases smoothly over the substrate, improving film uniformity.

Managing System Pressure

The overall pressure inside the tube is a critical process parameter. The gas control system uses throttle valves in conjunction with a vacuum pump to maintain a specific pressure.

Pressure influences the mean free path of gas molecules and the reaction kinetics, directly impacting the film's density, crystal structure, and deposition rate.

Key Components and Their Roles

Understanding the hardware that enables this control is crucial for any operator or researcher. These components are the hands that execute the chemical recipe.

Mass Flow Controllers (MFCs)

MFCs are the heart of the system's precision. For a given gas, an MFC delivers a highly accurate and repeatable flow rate (e.g., in standard cubic centimeters per minute, or sccm) regardless of fluctuations in gas pressure from the source cylinder.

Valves and Manifolds

A system of automated valves and tubing, known as a manifold, routes the gases from their sources, through the MFCs, and into the furnace tube. This allows for complex, programmable sequences, such as purging the system with inert gas before introducing the reactive precursors.

Pressure Controllers

Often integrated with a throttle valve on the exhaust line, these controllers measure the pressure inside the tube and dynamically adjust the valve's opening to maintain a stable, desired pressure setpoint.

Understanding the Pitfalls and Challenges

While powerful, a sophisticated gas control system introduces potential points of failure that can compromise results. Awareness is the first step toward prevention.

Contamination from Impurities

Even small leaks in fittings or the use of low-purity gas can introduce contaminants like oxygen or water vapor. These impurities can ruin a sensitive deposition process, leading to flawed or oxidized films.

Calibration Drift

Mass Flow Controllers are precise instruments that can drift over time. Without periodic calibration, a commanded flow rate of "10 sccm" may no longer be delivering exactly 10 sccm, leading to a lack of repeatability between experiments.

The Complexity of Multi-Gas Recipes

Managing the timing and flow rates of multiple gases requires careful programming. A mistake in the sequence—such as introducing precursors before the chamber is fully purged—can lead to poor film quality or even unsafe conditions.

Making the Right Choice for Your Goal

To leverage the gas control system effectively, you must align its capabilities with your specific research or production objective.

- If your primary focus is high-purity, single-crystal films: Prioritize a leak-tight system with high-purity gas sources and MFCs known for their stability.

- If your primary focus is process repeatability for production: Implement a strict calibration schedule for your MFCs and pressure controllers to ensure consistency run after run.

- If your primary focus is developing complex, layered materials: Master the programming interface of your system to create precise, automated recipes that control the gas mixture and timing for each layer.

By viewing the gas control system as the primary tool for chemical engineering, you unlock the full potential of your CVD furnace to create novel and high-performance materials.

Summary Table:

| Function | Key Components | Impact on Deposition |

|---|---|---|

| Supplies Precursors | Mass Flow Controllers (MFCs) | Determines chemical composition and film quality |

| Creates Reaction Atmosphere | Inert Gas Valves | Prevents oxidation and improves film uniformity |

| Manages System Pressure | Pressure Controllers | Influences density, crystal structure, and deposition rate |

Unlock the full potential of your material synthesis with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precise gas control systems in our Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures these solutions meet your unique experimental requirements for superior thin film deposition. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films