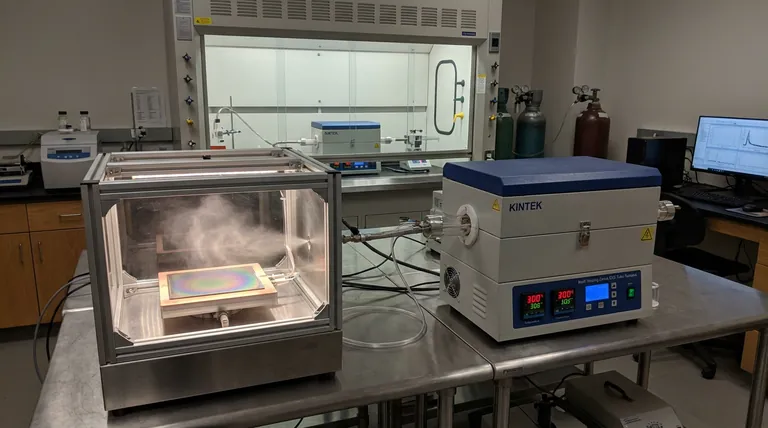

A customized spray pyrolysis chamber functions as the critical physical interface where liquid precursor solutions are transformed into solid thin films. It is specifically engineered to house an atomization device that converts these solutions into micron-sized droplets, ensuring they are deposited accurately and uniformly onto a heated substrate to form Antimony-doped ZnSe and PbSe layers.

Core Takeaway The chamber is not merely a container; it is a precision instrument designed to control the trajectory and thermal environment of precursor droplets. Its primary role is to facilitate the immediate transition from liquid mist to solid film across large surface areas, establishing the foundation for the material's structural integrity before any post-deposition treatment.

The Mechanics of Deposition Control

Precision Atomization

The chamber’s first duty is to house the atomization device.

This component breaks down the precursor solution into a fine mist of micron-sized droplets. This size reduction is vital for ensuring the chemicals are distributed evenly rather than pooling on the surface.

Trajectory and Coverage

Once atomized, the droplets must travel to the substrate without coalescing prematurely.

The customized chamber is designed to guide this mist to ensure accurate and uniform coverage. This is particularly essential when synthesizing films over large areas, where standard setups often result in uneven thickness.

The Role of Thermal Management

Providing Activation Energy

Inside the chamber, the substrate is not passive; it is placed on a heated platform.

Supplementary data indicates this platform often maintains a temperature around 80°C. This thermal input provides the necessary activation energy for the precursor droplets to undergo thermal decomposition upon contact.

Facilitating Solvent Evaporation

The controlled environment within the chamber manages the rate of solvent removal.

The heated platform promotes rapid evaporation of the carrier liquid. This allows the solid Antimony-doped ZnSe or PbSe materials to nucleate and grow effectively on the substrate surface immediately upon impact.

Understanding the Trade-offs

Deposition vs. Crystallization

It is critical to distinguish the function of the spray chamber from that of post-deposition equipment.

The spray chamber handles deposition and nucleation at lower temperatures (e.g., 80°C). It does not typically handle high-temperature recrystallization.

The Necessity of Post-Treatment

While the chamber creates the film, it does not finalize the material properties.

To eliminate internal stresses and increase grain size, the film usually requires a separate stage in a tube furnace at significantly higher temperatures (around 300°C). Relying solely on the spray chamber without this secondary step will likely result in films with lower carrier mobility and optical conductivity.

Making the Right Choice for Your Goal

To maximize the quality of your Antimony-doped ZnSe and PbSe thin films, you must view the spray chamber as the first step in a two-part system.

- If your primary focus is Film Uniformity: Prioritize the customization of the spray chamber's nozzle alignment and airflow to ensure consistent droplet distribution over the entire substrate.

- If your primary focus is Electronic Performance: Ensure your process includes a transfer from the spray chamber to a tube furnace, as the chamber alone provides nucleation but not the high-heat recrystallization needed for optimal conductivity.

The customized chamber guarantees the physical architecture of the film, while the subsequent heat treatment unlocks its electronic potential.

Summary Table:

| Feature | Function in Spray Pyrolysis Chamber | Impact on Thin Film Quality |

|---|---|---|

| Atomization Device | Converts precursors into micron-sized droplets | Ensures even distribution and prevents pooling |

| Trajectory Control | Guides mist accurately toward the substrate | Facilitates uniform coverage over large surface areas |

| Heated Platform | Maintains substrate temperature (approx. 80°C) | Provides activation energy for thermal decomposition |

| Solvent Evaporation | Rapidly removes carrier liquid during impact | Promotes effective nucleation and solid film growth |

Elevate Your Thin Film Research with KINTEK

Achieving the perfect physical architecture for Antimony-doped ZnSe and PbSe thin films requires precision at every stage. KINTEK provides the advanced equipment necessary to master both the initial deposition and the critical high-temperature recrystallization process.

Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique laboratory needs. Whether you are optimizing film uniformity in a spray chamber or enhancing electronic performance via high-heat treatment, our solutions deliver the reliability you demand.

Ready to unlock the full potential of your materials? Contact KINTEK today to consult with our specialists.

References

- Ikechukwu Christian Nworie, B. Ojobo. Comparative Assessment of Optical and Solid-State Characteristics in Antimony-Doped Chalcogenide Thin Films of ZnSe and PbSe to Boost Photovoltaic Performance in Solar Cells. DOI: 10.62292/njp.v33i1.2024.202

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Magnesium Extraction and Purification Condensing Tube Furnace

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What are the industrial applications of CVD processes? Unlock High-Performance Coatings for Your Industry

- What are the logistical challenges associated with CVD? Overcome Off-Site, Disassembly, and Waste Issues

- What is a CVD furnace? A Precision Tool for Building Advanced Materials

- What are the main advantages of Chemical Vapor Deposition (CVD)? Unlock High-Performance Thin Films

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- How can the physical characteristics of GaN crystal structures be adjusted? Precise Control via Growth Parameters

- What are the advantages of using a CVD tube furnace for preparing gate media? Achieve Superior Film Control and Purity

- What are the steps of the CVD process? Master the Key Stages for Superior Thin Films