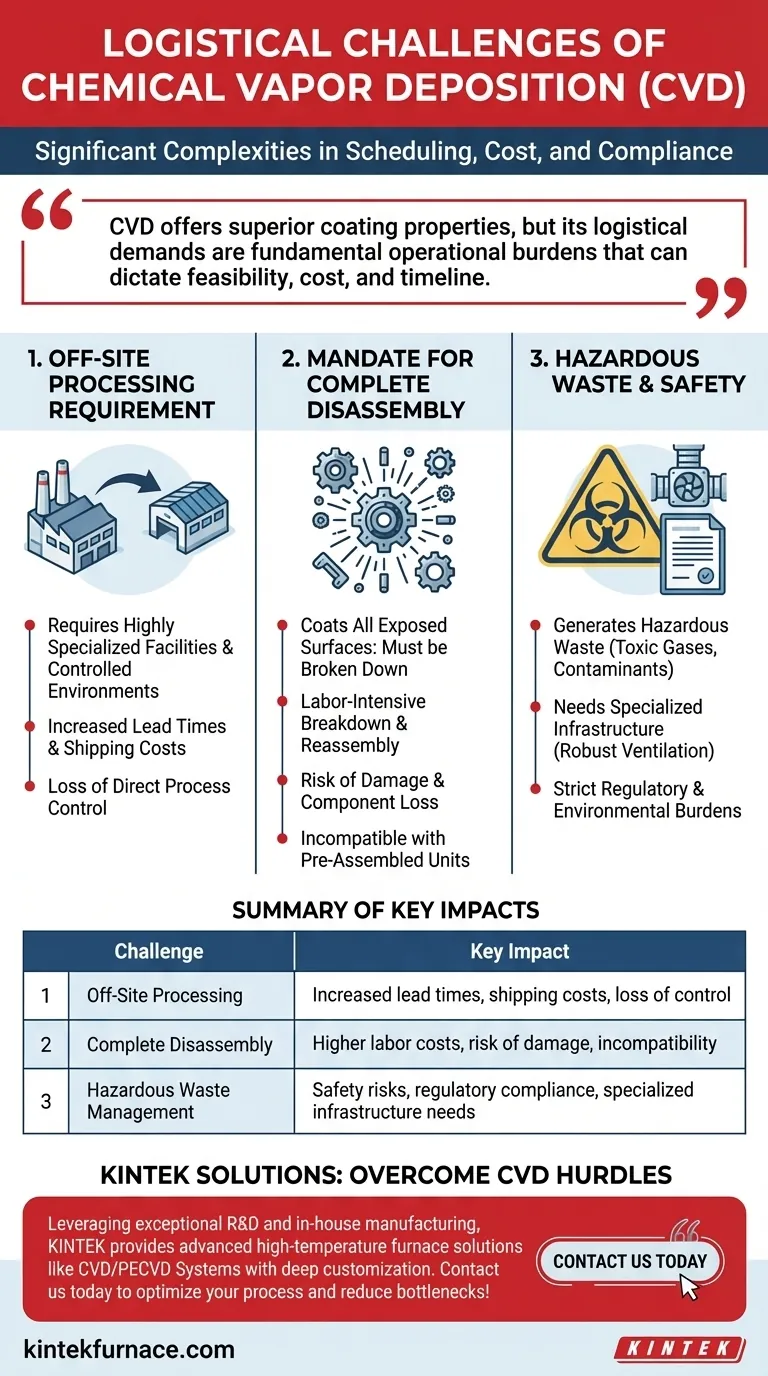

The primary logistical challenges associated with Chemical Vapor Deposition (CVD) are its off-site nature, the mandatory disassembly of all components before coating, and the management of hazardous waste. These factors introduce significant complexities in scheduling, cost, and compliance that are not immediately apparent from the technical specifications of the process alone.

While CVD offers superior coating properties, its logistical demands are not minor details; they are fundamental operational burdens that can dictate the feasibility, cost, and timeline of your entire project.

The Off-Site Processing Requirement

The most significant logistical hurdle is that CVD cannot be performed on a typical factory floor. The process requires highly specialized, capital-intensive equipment and controlled environments that are only found in dedicated coating centers.

Dependence on Specialized Facilities

CVD reactors are complex and operate under precise conditions of temperature, pressure, and gas flow. This necessitates facilities with advanced infrastructure, safety protocols, and trained personnel, making it impractical for most companies to bring the capability in-house.

Increased Lead Times and Shipping

This off-site dependency means you must factor in transit time and shipping costs for sending your parts to the coating center and receiving them back. This adds days or even weeks to your production cycle, creating a potential bottleneck.

Loss of Direct Process Control

When parts are sent to a third-party vendor, you inherently lose a degree of direct control over scheduling and quality assurance. Your production becomes reliant on the capacity and queue of the coating partner.

The Mandate for Complete Disassembly

CVD is a pervasive process that coats all exposed surfaces. Therefore, any product or assembly must be completely broken down into its individual components before being placed in the reactor.

Labor-Intensive Breakdown and Reassembly

This requirement adds significant labor costs and time both before and after the coating step. Each part must be carefully disassembled, tracked, coated, and then meticulously reassembled, which can be a time-consuming and manual process.

Risk of Damage and Component Loss

Every step of handling, disassembly, and reassembly introduces risk. Components can be damaged, lost, or reassembled incorrectly, potentially compromising the final product's integrity and leading to costly rework or scrap.

Incompatibility with Pre-Assembled Units

Crucially, this means CVD is fundamentally incompatible with components that are permanently assembled or cannot be feasibly taken apart. You cannot, for instance, coat an already-welded frame or a sealed electronic unit.

Understanding the Trade-offs: Waste and Safety

Beyond scheduling and labor, CVD introduces significant safety and environmental compliance challenges that carry their own logistical weight. These are not just operational details but serious regulatory responsibilities.

Managing Hazardous By-products

The CVD process inherently generates hazardous waste. This includes toxic residual gases from spent precursors and equipment components that become contaminated over time.

The Need for Specialized Infrastructure

Safe operation requires robust ventilation systems to handle toxic fumes and established protocols for the proper handling, storage, and disposal of hazardous materials. This infrastructure represents a major barrier to entry for in-house operation.

Regulatory and Environmental Burdens

Managing hazardous waste is governed by strict local and federal regulations. Outsourcing to a specialized center transfers this burden, but it remains an implicit cost and a critical factor in selecting a reputable and compliant coating partner.

Factoring Logistics into Your CVD Decision

To make an informed choice, you must weigh the exceptional performance of CVD coatings against these substantial logistical demands. Your project's specific goals will determine if the trade-offs are acceptable.

- If your primary focus is low-volume production or prototyping: The logistical overhead of using a third-party coating center is often perfectly manageable and cost-effective.

- If your primary focus is high-volume, integrated manufacturing: The required disassembly, shipping, and reassembly cycle can become a major bottleneck that jeopardizes production targets and timelines.

- If your primary focus is coating large or complex assemblies: CVD is likely not a viable option if the item cannot be completely and economically broken down into its constituent parts.

Ultimately, a successful CVD implementation depends on acknowledging these logistical costs as a core part of the process, not as an afterthought.

Summary Table:

| Challenge | Key Impact |

|---|---|

| Off-Site Processing | Increased lead times, shipping costs, loss of control |

| Complete Disassembly | Higher labor costs, risk of damage, incompatibility with assemblies |

| Hazardous Waste Management | Safety risks, regulatory compliance, specialized infrastructure needs |

Struggling with CVD logistical challenges? KINTEK can help! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like CVD/PECVD Systems with deep customization to meet your unique needs. Contact us today to optimize your process and reduce bottlenecks!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition