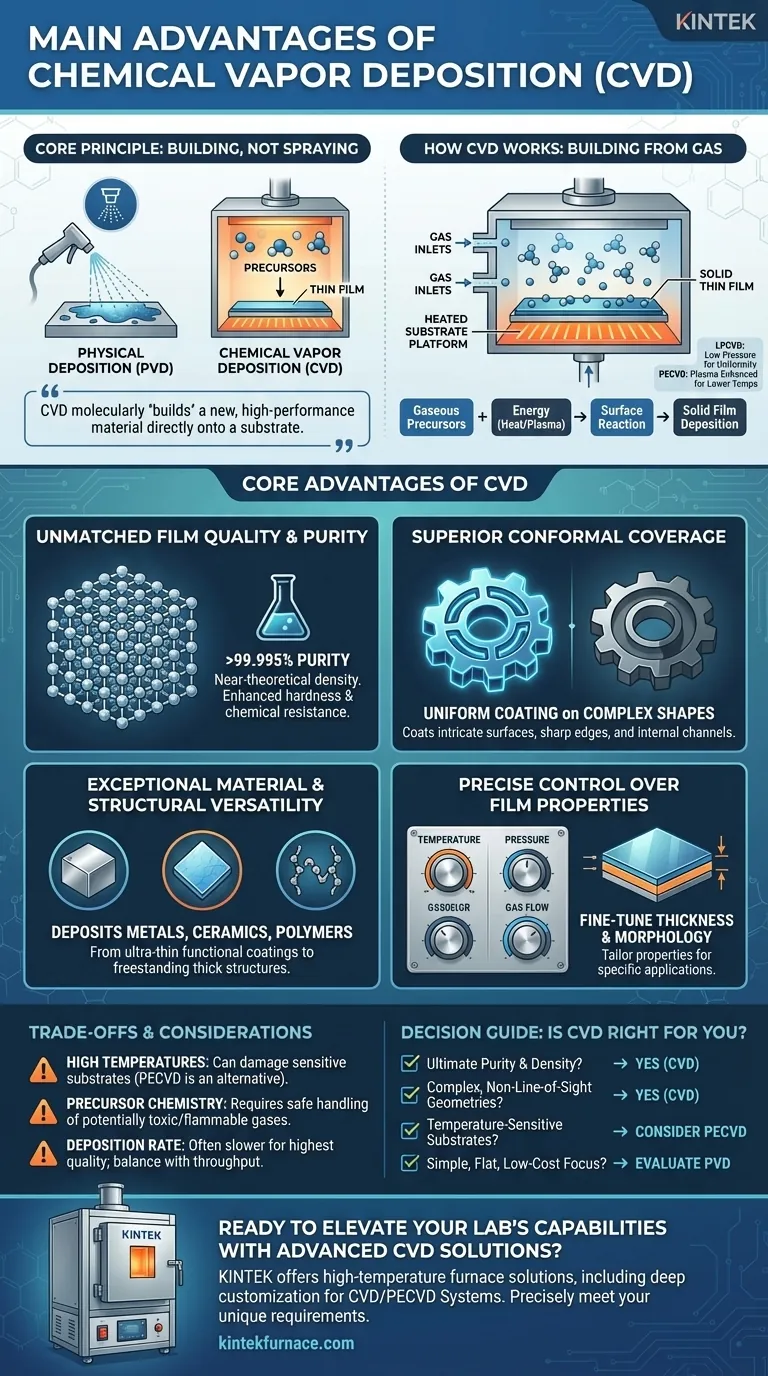

At its core, Chemical Vapor Deposition (CVD) offers unparalleled versatility and precision in creating high-performance thin films. The process excels at producing exceptionally pure, uniform, and durable coatings that conform perfectly to even the most complex surfaces. This combination of material quality and geometric flexibility makes it a cornerstone technology in demanding industries from semiconductors to aerospace.

The true power of CVD lies not just in applying a coating, but in its ability to molecularly "build" a new, high-performance material directly onto a substrate. This provides a level of purity and conformal coverage that physical deposition methods often cannot match.

How Chemical Vapor Deposition Works

To understand the advantages of CVD, it is essential to grasp its fundamental principle. Unlike processes that simply spray or plate a material, CVD constructs a film through a chemical reaction.

The Basic Principle: Building from Gas

CVD introduces gaseous precursor molecules into a reaction chamber containing a substrate. When energy (typically heat) is applied, these gases react on the substrate's surface, depositing a solid, dense, and highly adherent thin film.

The film is quite literally built up molecule by molecule, resulting in a fundamentally different and often superior structure compared to physically applied coatings.

Key Variants for Broader Applications

Different types of CVD have been developed to meet specific needs.

Low-Pressure CVD (LPCVD) reduces the chamber pressure, which enhances the uniformity of the film across the substrate and minimizes unwanted reactions in the gas phase.

Plasma-Enhanced CVD (PECVD) uses plasma to energize the precursor gases. This allows the deposition reaction to occur at much lower temperatures, making it suitable for coating temperature-sensitive materials like polymers or pre-built electronic devices.

Core Advantages of the CVD Process

The unique nature of the CVD process gives rise to several key advantages that set it apart from other thin-film deposition techniques.

Unmatched Film Quality and Purity

Because CVD is a chemical process, it can produce films of exceptionally high purity, often exceeding 99.995%.

The resulting films have a near-theoretical density and a low defect count. This leads to superior performance characteristics, such as enhanced hardness, chemical resistance, and electrical properties.

Superior Conformal Coverage

One of CVD's most significant advantages is its ability to create conformal coatings. This means the film deposits at a uniform thickness across the entire surface, regardless of its complexity.

CVD can flawlessly coat intricate 3D shapes, sharp edges, and even the inside of long, narrow channels—feats that are difficult or impossible for line-of-sight processes like Physical Vapor Deposition (PVD).

Exceptional Material and Structural Versatility

CVD is not limited to a single class of materials. It can be used to deposit a vast range of substances, including metals, ceramics, and some polymers.

Furthermore, the process can be used to create everything from ultra-thin functional coatings to freestanding, thick-walled structures of near-net complex shapes, offering tremendous design flexibility.

Precise Control Over Film Properties

The deposition is governed by parameters like temperature, pressure, and gas flow rates. These can be controlled with high precision.

This control allows for the fine-tuning of the final film's thickness and morphology, enabling engineers to tailor the material's properties for a specific application.

Understanding the Trade-offs and Considerations

While powerful, CVD is not a universal solution. Understanding its limitations is critical for making an informed decision.

The Challenge of High Temperatures

Traditional thermal CVD often requires very high temperatures (several hundred to over a thousand degrees Celsius) to initiate the chemical reaction.

This high heat requirement can damage or destroy thermally sensitive substrates. While PECVD offers a lower-temperature alternative, it may involve trade-offs in film properties or purity.

Precursor Chemistry and Safety

The "chemical" in CVD involves the use of precursor gases. These materials can be highly toxic, flammable, or corrosive, requiring specialized, expensive equipment and strict safety protocols for handling and disposal.

Deposition Rate and Throughput

Achieving the highest quality and most uniform films often requires a slow, carefully controlled deposition rate. For applications where high throughput and low cost are the primary drivers, faster but less precise methods may be more suitable.

Is CVD the Right Choice for Your Application?

Choosing a deposition technology depends entirely on your project's specific priorities and constraints.

- If your primary focus is ultimate purity and film density: CVD is likely the superior choice, especially for critical applications like semiconductors or high-performance optics.

- If you need to coat complex, non-line-of-sight geometries: CVD's conformal nature is a decisive advantage that is very difficult to replicate with other methods.

- If you are working with temperature-sensitive substrates: You must consider lower-temperature variants like PECVD or explore alternative deposition methods entirely.

- If your main driver is low cost for simple, flat surfaces: You should evaluate if physical vapor deposition (PVD) or other coating methods offer a more cost-effective solution.

By understanding these core principles and trade-offs, you can confidently determine if CVD's unique capabilities align with your engineering goals.

Summary Table:

| Advantage | Description |

|---|---|

| Unmatched Film Quality and Purity | Produces high-purity films (>99.995%) with near-theoretical density, enhancing hardness and chemical resistance. |

| Superior Conformal Coverage | Ensures uniform coating on complex 3D shapes, edges, and internal channels, unlike line-of-sight methods. |

| Material and Structural Versatility | Deposits metals, ceramics, and polymers, from thin coatings to freestanding structures. |

| Precise Control Over Film Properties | Allows fine-tuning of thickness and morphology through temperature, pressure, and gas flow control. |

Ready to elevate your lab's capabilities with advanced CVD solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for industries like semiconductors and aerospace. Contact us today to discuss how our tailored CVD systems can deliver superior thin films for your projects!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films