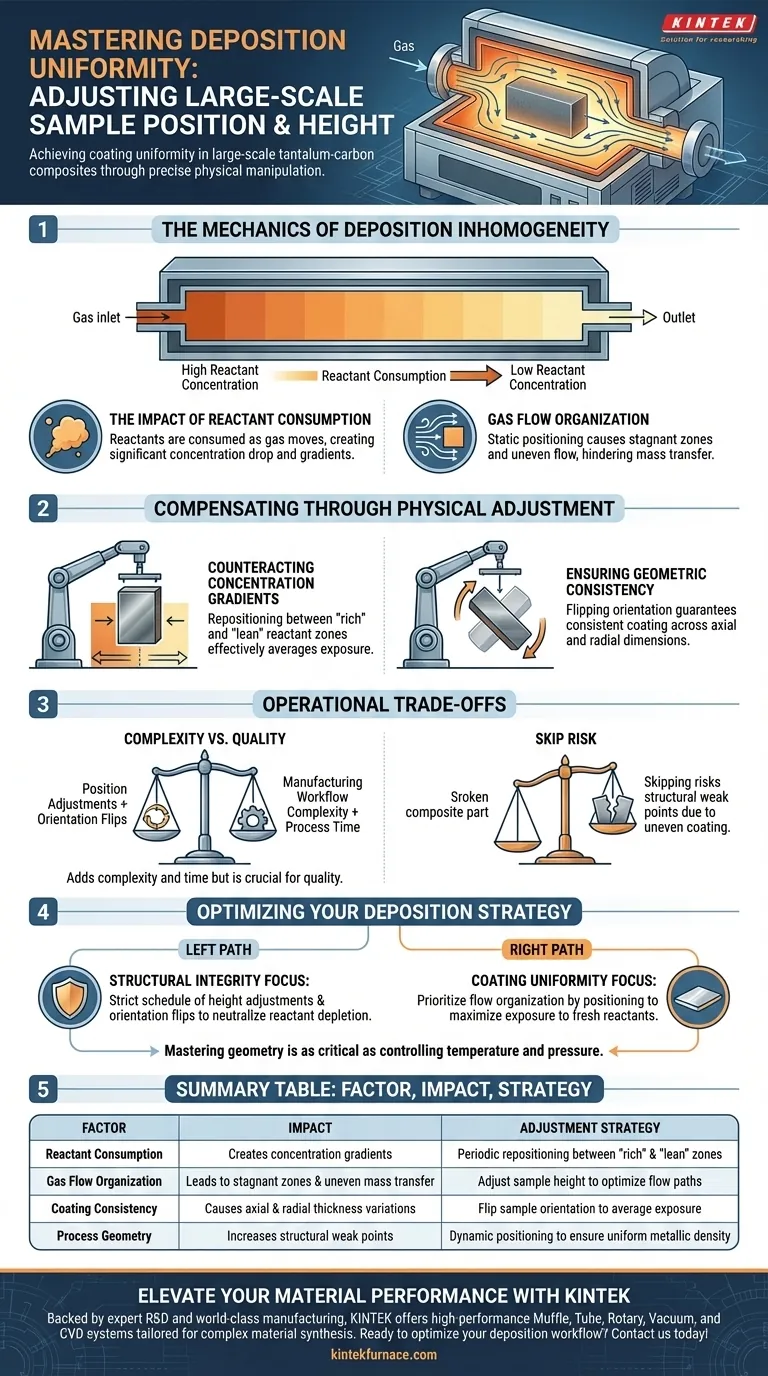

Achieving coating uniformity in large-scale tantalum-carbon composites requires precise physical manipulation of the sample during production. Adjusting the position and height within the chamber is necessary to optimize gas flow organization and strictly manage the mass transfer process. Without these adjustments, the natural consumption of reactants creates uneven concentration gradients, leading to inconsistent metallic coatings across the material.

In a high-temperature deposition furnace, reactants are actively consumed as they travel, creating zones of varying gas concentration. Systematically adjusting sample position and flipping orientation compensates for these gradients, ensuring consistent coating quality in both axial and radial dimensions.

The Mechanics of Deposition Inhomogeneity

The Impact of Reactant Consumption

The fundamental challenge in preparing large-scale composites is that reactants are consumed as the process unfolds.

As the gas mixture moves through the high-temperature furnace, the chemical components required for the coating are depleted.

This results in a significant drop in reactant concentration from the inlet to the outlet, creating a "gradient" rather than a uniform atmosphere.

Gas Flow Organization

Static positioning within the chamber often leads to stagnant zones or uneven flow paths.

Adjusting the height of the sample directly influences how the gas flows around and through the composite structure.

Optimizing this gas flow organization is critical for efficient mass transfer, ensuring the reactants actually reach the surface of the material.

Compensating Through Physical Adjustment

Counteracting Concentration Gradients

Because the gas concentration is not uniform, a stationary sample will inevitably develop a coating that is thicker in some areas and thinner in others.

Changing the sample's position moves it between "rich" and "lean" reactant zones.

This movement effectively averages out the exposure, preventing structural inconsistencies caused by localized depletion.

Ensuring Geometric Consistency

Large-scale materials are particularly susceptible to variations across their length (axial) and width (radial).

Flipping the sample's orientation is a critical step to ensure the metallic coating is applied evenly across the entire geometry.

This mechanical intervention guarantees better axial and radial consistency, which is essential for the final performance of the tantalum-carbon composite.

Operational Trade-offs

Complexity vs. Quality

Introducing position adjustments and orientation flips adds complexity to the manufacturing workflow.

It requires precise intervention, which may increase process time compared to a static deposition approach.

However, skipping this step risks producing a composite with significant structural weak points due to uneven coating thickness.

Optimizing Your Deposition Strategy

To maximize the quality of your tantalum-carbon composites, you must treat sample positioning as a dynamic variable.

- If your primary focus is structural integrity: Implement a strict schedule of height adjustments and orientation flips to neutralize the effects of reactant depletion.

- If your primary focus is coating uniformity: Prioritize flow organization by positioning samples to maximize exposure to fresh reactant streams before consumption occurs.

Mastering the geometry of sample placement is just as critical as controlling temperature and pressure for producing high-performance composites.

Summary Table:

| Factor | Impact on Deposition | Adjustment Strategy |

|---|---|---|

| Reactant Consumption | Creates concentration gradients from inlet to outlet | Periodic repositioning between 'rich' and 'lean' zones |

| Gas Flow Organization | Leads to stagnant zones and uneven mass transfer | Adjust sample height to optimize flow paths around geometry |

| Coating Consistency | Causes axial and radial thickness variations | Flip sample orientation to average exposure across all surfaces |

| Process Geometry | Increases structural weak points in large-scale parts | Dynamic positioning to ensure uniform metallic density |

Elevate Your Material Performance with KINTEK

Precision in sample positioning is only half the battle; the right thermal environment is the other. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for complex material synthesis. Whether you are developing advanced tantalum-carbon composites or specialized thin films, our customizable lab high-temperature furnaces provide the stability and flow control your research demands.

Ready to optimize your deposition workflow? Contact us today to discover how our custom furnace solutions can solve your most challenging uniformity issues!

Visual Guide

References

- Junyu Zhu, Haohong Jiang. Fabrication and mechanical properties of porous tantalum carbon composites by chemical vapor deposition. DOI: 10.1038/s41598-025-86680-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the typical temperature conditions for the CVD process? Optimize Your Thin Film Deposition

- What tasks do ultrasonic cleaning and ion sputtering systems perform in PVD? Achieve Atomic-Level Coating Adhesion

- What are the disadvantages of chemical Vapour deposition method? High Costs, Complexity & Material Limits

- Where is CVD used? Unlocking High-Performance Materials in Electronics, Energy & Aerospace

- How are CVD furnaces utilized in the energy sector? Powering Solar and Battery Innovations

- What materials are used in the hot zone of CVD furnaces? Optimize for Purity, Cost, and Performance

- What role do Chemical Vapor Deposition (CVD) systems play in MoSe2 synthesis? Achieve Atomic-Level Precision Control

- What role does a Chemical Vapor Deposition (CVD) system play in the synthesis of NCNTs? Precision Material Engineering