Chemical Vapor Deposition (CVD) is a cornerstone technology used to manufacture the most advanced materials that power our world. Its applications span the electronics, energy, aerospace, and biomedical industries, where it is used to create everything from the microchips in your phone to protective coatings on jet engine parts and biocompatible layers on medical implants.

At its core, CVD is not just about a single application but about a fundamental capability: the ability to build high-purity, ultra-thin films of material one atomic layer at a time. This precise control is why it has become indispensable for nearly every field of modern technology.

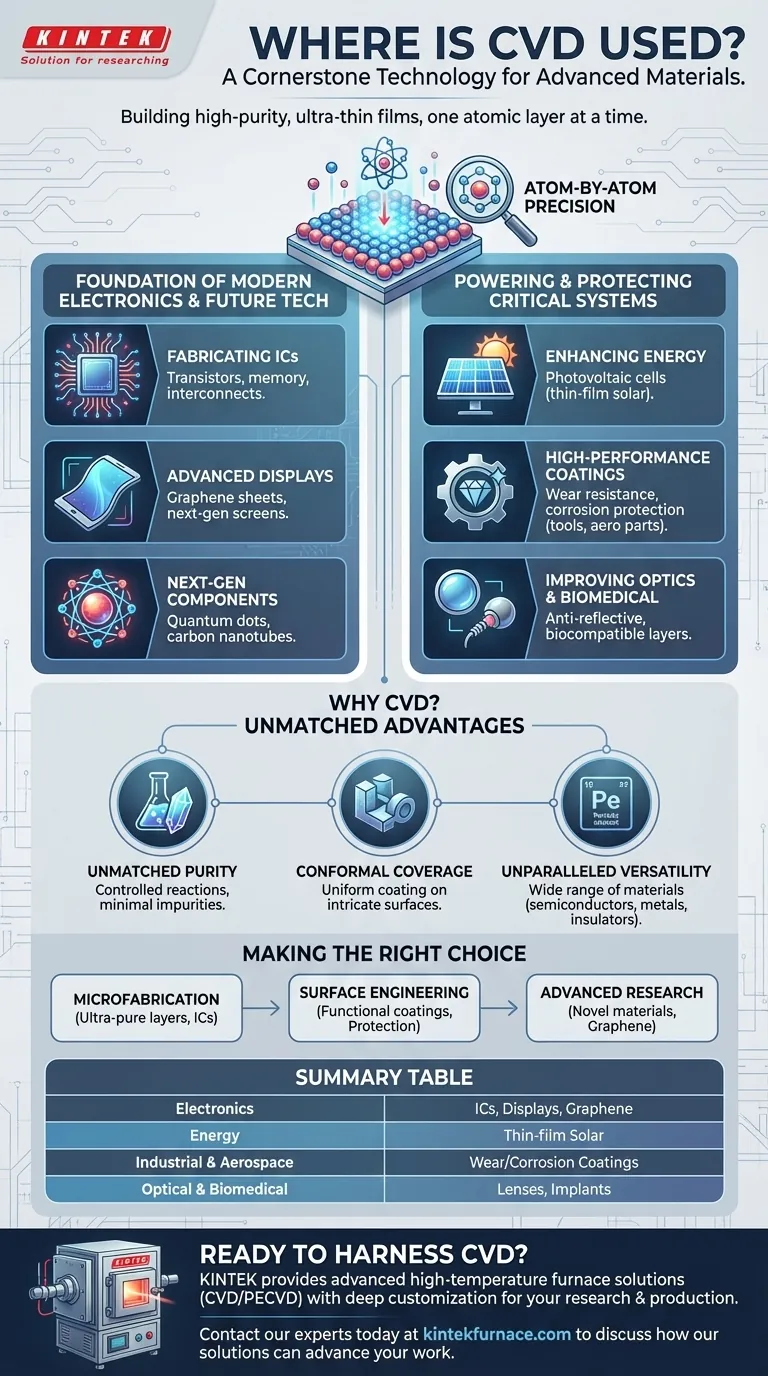

The Foundation of Modern Electronics

CVD is the workhorse of the semiconductor industry. The fabrication of complex microelectronics would be impossible without its ability to deposit pristine, functional layers on a microscopic scale.

Fabricating Integrated Circuits

The processors and memory chips that form the brain of every electronic device rely on CVD. It is used to deposit the thin films that create transistors, including active semiconductor layers (like silicon or gallium arsenide), insulating gate dielectrics, and conductive metal interconnects (like tungsten).

Building Advanced Displays

Next-generation displays for televisions and mobile devices leverage materials synthesized via CVD. For example, it is a key method for producing large-area graphene sheets, which promise to enable flexible, transparent, and highly efficient screens.

Enabling Next-Generation Components

The technology is also instrumental in creating novel materials for future electronics. This includes synthesizing quantum dots for more efficient displays and carbon nanotubes for advanced transistors and interconnects.

Powering and Protecting Critical Systems

Beyond microchips, CVD is essential for creating robust and efficient components for energy, industrial, and optical applications. Its value lies in modifying a material's surface to give it entirely new properties.

Enhancing Energy Production

CVD is widely used in the solar industry to manufacture photovoltaic cells. It deposits the thin films of amorphous polysilicon that are responsible for converting sunlight into electricity, directly contributing to the efficiency of solar panels.

Creating High-Performance Coatings

The process can apply exceptionally hard and durable coatings to a variety of surfaces. Synthetic diamond films on cutting tools dramatically increase their lifespan, while specialized coatings on automotive and aerospace parts provide critical resistance to wear and corrosion.

Improving Optical Devices

From everyday sunglasses to specialized scientific instruments, CVD is used to apply thin films that control the reflection and transmission of light. This includes anti-reflective coatings on lenses, UV-blocking layers on architectural glass, and protective layers on optical windows used in harsh environments.

Understanding the Trade-offs: Why CVD is Chosen

CVD is not always the simplest or cheapest method for applying a film, but it is chosen when performance and precision are non-negotiable. Its dominance comes from three key advantages that other techniques cannot easily match.

Unmatched Purity

Because CVD is based on controlled chemical reactions using highly pure precursor gases, the resulting films are exceptionally pure. This is critical in semiconductor manufacturing, where even microscopic impurities can cause a device to fail.

Conformal Coverage

Unlike line-of-sight deposition methods, CVD gases can coat all surfaces of a complex, three-dimensional object with a perfectly uniform film. This "conformal coverage" is essential for ensuring complete protection on intricate parts and for fabricating modern, non-planar transistors.

Unparalleled Versatility

The sheer variety of precursor chemicals available allows CVD to deposit an enormous range of materials. This includes semiconductors (silicon), insulators (oxides, nitrides), and pure metals (tungsten), making it a single, flexible platform for building complex, multi-layered devices.

Making the Right Choice for Your Goal

The decision to use CVD is driven by the specific material properties you need to achieve.

- If your primary focus is microfabrication: CVD is the industry standard for creating the ultra-pure, atomically precise layers required for transistors and integrated circuits.

- If your primary focus is surface engineering: CVD is the ideal choice for adding a high-performance functional coating—like wear resistance, corrosion protection, or biocompatibility—to a component.

- If your primary focus is advanced materials research: CVD provides the fine control needed to synthesize and explore novel materials like graphene, carbon nanotubes, and quantum dots.

Ultimately, Chemical Vapor Deposition is the enabling process that transforms raw materials into high-performance, functional surfaces.

Summary Table:

| Application Area | Key CVD Uses |

|---|---|

| Electronics | Fabricating transistors, memory chips, and advanced displays (e.g., graphene). |

| Energy | Manufacturing thin-film solar cells for photovoltaic panels. |

| Industrial & Aerospace | Applying ultra-hard, wear-resistant coatings on cutting tools and engine parts. |

| Optical & Biomedical | Creating anti-reflective lenses, UV-blocking glass, and biocompatible implant coatings. |

Ready to harness the power of CVD for your research or production?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for CVD and PECVD processes. Whether you are developing next-generation semiconductors, synthesizing novel materials like graphene, or applying high-performance coatings, our product line—including Tube Furnaces, Vacuum & Atmosphere Furnaces, and dedicated CVD/PECVD Systems—is designed to meet your precise requirements. Our strong deep customization capability ensures your unique experimental or production goals are achieved.

Contact our experts today to discuss how our solutions can advance your work.

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- How does the gas control system in a CVD tube furnace enhance its functionality? Achieve Precise Thin Film Deposition

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition