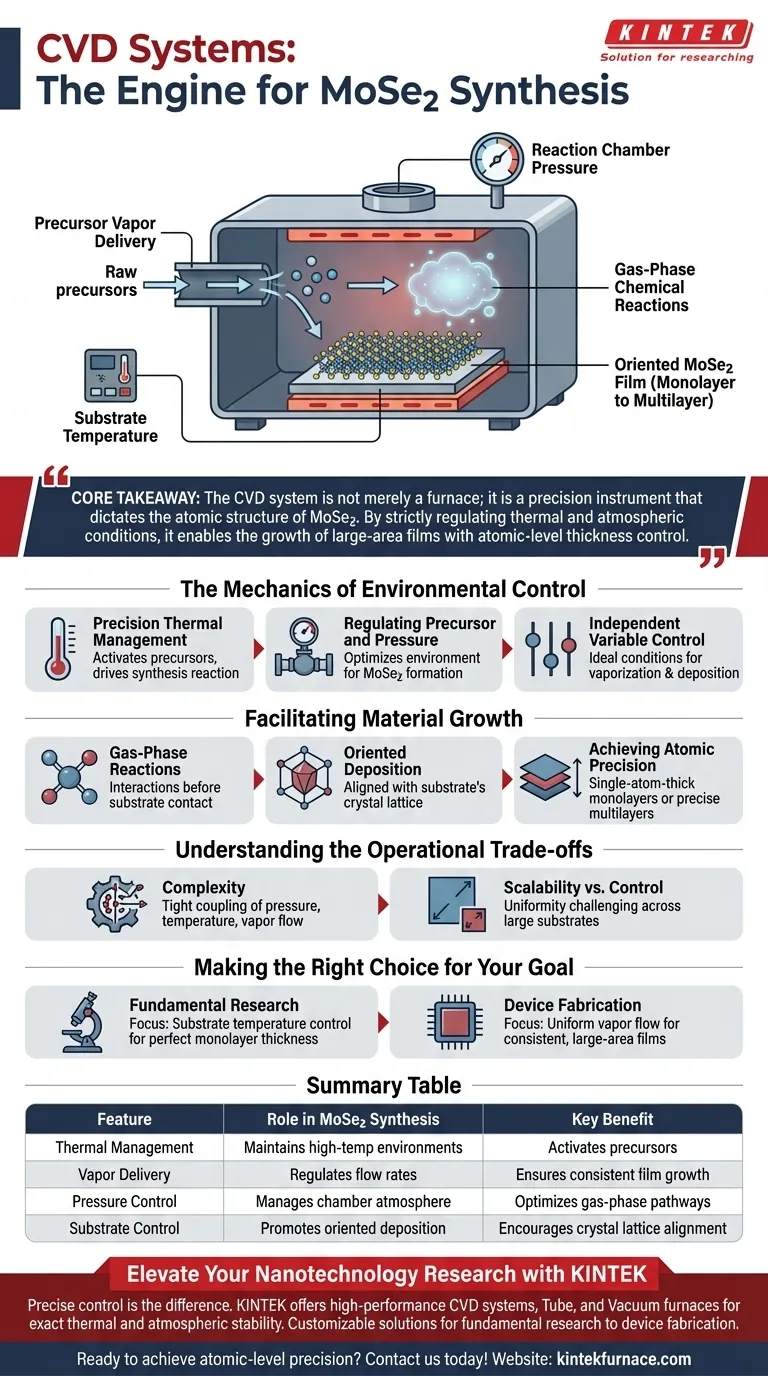

Chemical Vapor Deposition (CVD) systems serve as the critical infrastructure for synthesizing Molybdenum diselenide (MoSe2) by establishing a precisely controlled high-temperature reaction environment. They actively manage three specific variables—precursor vapor delivery, reaction chamber pressure, and substrate temperature—to facilitate gas-phase chemical reactions. This control is the deciding factor in transforming raw precursors into oriented, high-quality films on a target substrate.

Core Takeaway The CVD system is not merely a furnace; it is a precision instrument that dictates the atomic structure of MoSe2. By strictly regulating thermal and atmospheric conditions, it enables the growth of large-area films with atomic-level thickness control, ranging from monolayers to specific multilayer structures.

The Mechanics of Environmental Control

Precision Thermal Management

The fundamental role of the CVD system is to generate and maintain a high-temperature environment. This heat provides the necessary energy to activate the chemical precursors and drive the synthesis reaction.

Regulating Precursor and Pressure

The system governs the rate at which precursor vapors enter the reaction zone. Simultaneously, it controls the chamber pressure, ensuring the environment is optimized for the specific chemical pathways required to form MoSe2.

Independent Variable Control

While the reaction occurs in a single system, the ability to manage substrate temperature independently from precursor delivery is vital. This separation ensures that the conditions are ideal for both the vaporization of raw materials and their subsequent deposition.

Facilitating Material Growth

Gas-Phase Chemical Reactions

The CVD system creates the conditions necessary for reactions to occur in the gas phase. This ensures that the precursors interact chemically before or during their contact with the substrate, rather than simply settling as dust.

Oriented Deposition

The system promotes oriented deposition, meaning the material does not grow randomly. Instead, the controlled environment encourages the MoSe2 molecules to align effectively with the substrate's crystal lattice.

Achieving Atomic Precision

The ultimate output of this controlled process is atomic-level accuracy. The system allows researchers to target specific thicknesses, reliably producing either single-atom-thick monolayers or precisely defined multilayers.

Understanding the Operational Trade-offs

The Complexity of Interdependent Variables

The primary challenge in using CVD for MoSe2 is the tight coupling of variables. Because the system relies on the precise balance of pressure, temperature, and vapor flow, a deviation in one area (e.g., a slight pressure drop) can disrupt the gas-phase reaction dynamics.

Scalability vs. Control

While CVD systems enable the growth of large-area films, maintaining uniformity across larger substrates becomes increasingly difficult. The "precise control" highlighted in the primary reference must be maintained across the entire physical zone, which requires rigorous system calibration.

Making the Right Choice for Your Goal

To maximize the effectiveness of a CVD system for MoSe2 synthesis, align your focus with your specific output requirements:

- If your primary focus is Fundamental Research: Prioritize systems with the finest control over substrate temperature to achieve perfect monolayer atomic thickness.

- If your primary focus is Device Fabrication: Focus on systems capable of maintaining uniform precursor vapor flow to ensure consistent, high-quality large-area films.

The CVD system acts as the bridge between raw chemistry and functional nanotechnology, turning volatile precursors into structured, atomic-scale precision materials.

Summary Table:

| Feature | Role in MoSe2 Synthesis | Key Benefit |

|---|---|---|

| Thermal Management | Maintains high-temperature environments | Activates precursors for chemical reactions |

| Vapor Delivery | Regulates precursor flow rates | Ensures consistent film growth and thickness |

| Pressure Control | Manages reaction chamber atmosphere | Optimizes specific gas-phase chemical pathways |

| Substrate Control | Promotes oriented deposition | Encourages crystal lattice alignment for monolayers |

Elevate Your Nanotechnology Research with KINTEK

Precise control is the difference between random deposition and high-quality MoSe2 monolayers. Backed by expert R&D and manufacturing, KINTEK offers high-performance CVD systems, Tube, and Vacuum furnaces designed to deliver the exact thermal and atmospheric stability your synthesis requires.

Whether you are conducting fundamental research on atomic structures or scaling up for device fabrication, our customizable systems are engineered to meet your unique lab needs.

Ready to achieve atomic-level precision? Contact us today to find your solution!

Visual Guide

References

- Guilherme Araújo, Andrea Capasso. Interface Engineering of Chemical Vapor‐Deposited 2D MoSe<sub>2</sub>. DOI: 10.1002/pssr.202500124

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- Why is a vacuum pump required for CVD graphene growth? Ensure High-Purity Material Synthesis

- What types of materials can be deposited using CVD in microfabrication? Explore Versatile Thin Films for Your Devices

- What is the role of an open-flow cold-wall CVD system in HfO2 preparation? Achieve High Purity & Uniformity

- What are the advantages of TMGa in MOCVD of beta-gallium oxide? Achieve High Growth Rates and Industrial Scalability

- What is a major advantage of chemical vapor? It Sterilizes Without Rusting Your Metal Instruments

- What is Chemical Vapor Deposition (CVD), and how do horizontal furnaces facilitate it? Unlock High-Purity Thin Films

- What physical conditions affect graphene production? Master CVD Synthesis for High-Quality Results

- What is an example of a chemical vapor deposition? Build High-Performance Thin Films Atom by Atom