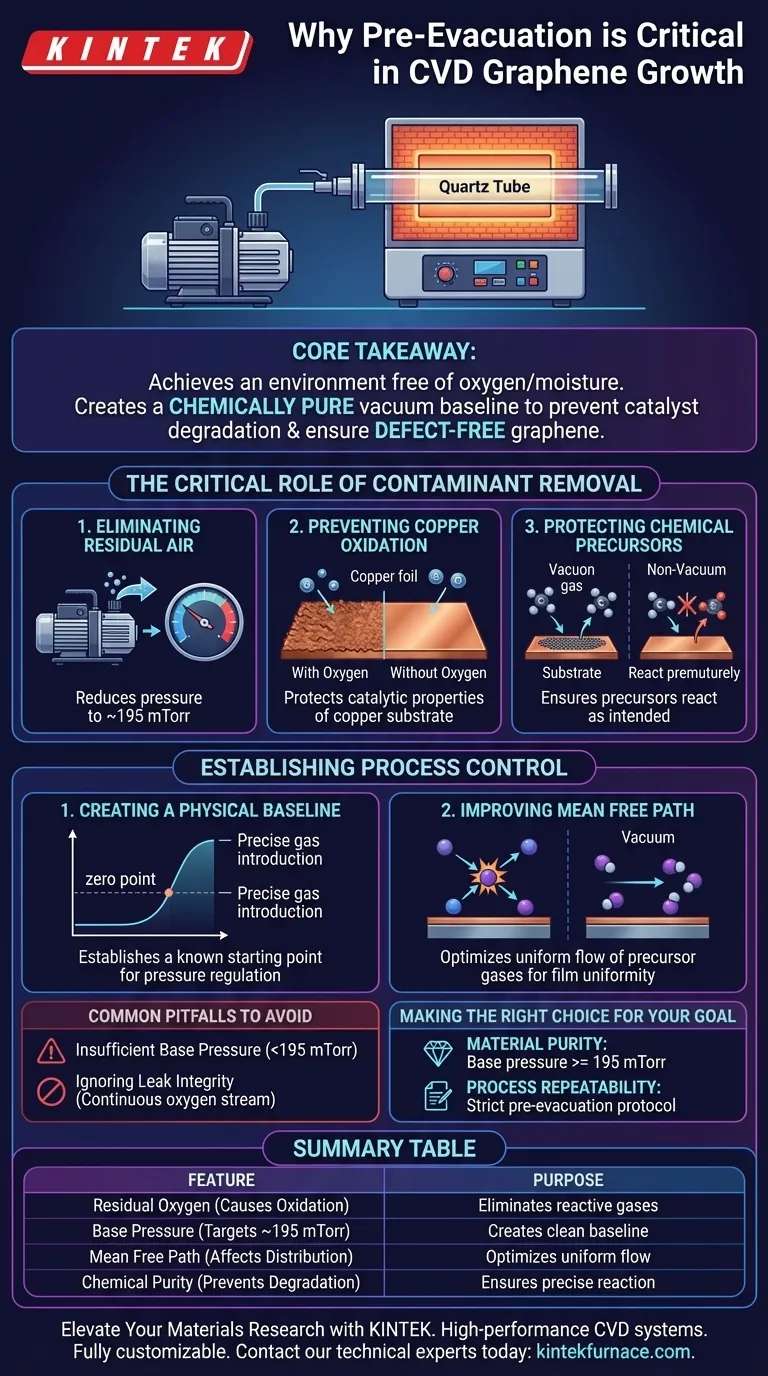

The primary reason a vacuum pump is required in Chemical Vapor Deposition (CVD) is to evacuate residual air and impurities from the quartz tube before heating begins. By reducing the system's base pressure to approximately 195 mTorr, the pump eliminates contaminants that would otherwise oxidize the copper substrate and compromise the structural integrity of the graphene.

Core Takeaway Achieving high-quality graphene requires an environment free of atmospheric oxygen and moisture. Pre-evacuation serves as the critical "reset" button, creating a chemically pure vacuum baseline that prevents catalyst degradation and ensures the growth of defect-free material.

The Critical Role of Contaminant Removal

Eliminating Residual Air

The atmosphere contains gases, primarily oxygen and nitrogen, that interfere with the delicate chemical reactions of CVD.

Before the system is heated, an industrial-grade vacuum pump must exhaust these gases from the furnace chamber. This reduces the pressure significantly, often targeting a base pressure of roughly 195 mTorr to ensure the environment is pristine.

Preventing Copper Oxidation

Graphene growth typically relies on a copper foil substrate acting as a catalyst.

If residual air remains in the tube during the heating phase, the oxygen will react with the copper foil. This causes the copper to oxidize, which degrades its catalytic properties and ruins the surface foundation necessary for proper graphene lattice formation.

Protecting Chemical Precursors

Beyond the substrate, the carbon precursors (the gases used to build the graphene) are highly sensitive.

In a non-evacuated environment, these precursors can suffer from premature oxidation before they even reach the substrate. A high-vacuum environment ensures that the precursors react only as intended, rather than burning up or forming unwanted byproducts due to background impurities.

Establishing Process Control

Creating a Physical Baseline

Pre-evacuation is not just about cleaning; it is about establishing a known starting point for pressure regulation.

You cannot accurately control the deposition pressure if the chamber is filled with random atmospheric variables. Evacuating the system provides a "zero point" (or near-zero), allowing operators to precisely introduce gases to reach the specific controlled deposition pressure (such as 3 Torr) required for growth.

Improving Mean Free Path

Reducing the pressure removes physical obstacles for gas molecules.

By exhausting air, the "mean free path"—the distance a molecule travels before hitting another—is optimized. This allows for a more uniform flow of precursor gases across the substrate, leading to higher uniformity in the resulting graphene film.

Common Pitfalls to Avoid

Insufficient Base Pressure

If the vacuum pump cannot reach the target base pressure (e.g., 195 mTorr or lower), residual oxygen remains a threat.

Failing to reach this threshold almost invariably leads to defects in the graphene structure or patchy growth caused by oxidized spots on the copper foil.

Ignoring Leak Integrity

A vacuum pump is only as effective as the seal of the system.

Even with a powerful pump, small leaks in the quartz tube or flanges will introduce a continuous stream of oxygen. This dynamic equilibrium—where air enters as fast as it is pumped out—will defeat the purpose of pre-evacuation and degrade the material quality.

Making the Right Choice for Your Goal

To ensure your CVD process yields the best possible results, consider your specific priorities:

- If your primary focus is Material Purity: Ensure your vacuum pump is rated to achieve and maintain a base pressure of at least 195 mTorr (or lower) to completely eliminate oxidation risks.

- If your primary focus is Process Repeatability: Implement a strict pre-evacuation protocol that requires hitting the specific base pressure baseline before any heating elements are activated.

Ultimately, the vacuum pump is the gatekeeper of quality, transforming a chaotic atmospheric chamber into the controlled reactor necessary for atomic-level precision.

Summary Table:

| Feature | Impact on Graphene Growth | Purpose of Pre-Evacuation |

|---|---|---|

| Residual Oxygen | Causes copper catalyst oxidation | Eliminates reactive gases before heating |

| Base Pressure | Targets ~195 mTorr for purity | Creates a clean, repeatable chemical baseline |

| Mean Free Path | Affects gas molecule distribution | Optimizes uniform flow of precursor gases |

| Chemical Purity | Prevents precursor degradation | Ensures carbon atoms react only on the substrate |

Elevate Your Materials Research with KINTEK

Precision in graphene growth starts with a pristine vacuum environment. KINTEK provides high-performance CVD systems designed to meet the rigorous demands of modern laboratories. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your unique research needs.

Don't let atmospheric impurities compromise your results. Partner with KINTEK to achieve atomic-level precision and superior process repeatability.

Contact our technical experts today to find your custom solution

Visual Guide

References

- Jia Tu, Mingdi Yan. Chemical Vapor Deposition of Monolayer Graphene on Centimeter-Sized Cu(111) for Nanoelectronics Applications. DOI: 10.1021/acsanm.5c00588

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- Why is it necessary to adjust sample position in deposition chambers for large-scale tantalum-carbon composites?

- What is the role of a Chemical Vapor Deposition (CVD) system? Precision Growth for Nanoporous Capillary Grippers

- How are CVD furnaces used in nanomaterial synthesis? Unlock High-Purity Materials for Advanced Applications

- What are the advantages of chemical vapor deposition? Achieve Superior, Conformal Films for Complex 3D Structures

- What role does a Rapid Thermal Processing (RTP) system play in MoS2 thin films? Achieve Precise Atomic Layer Control

- What is a CVD system? Achieve Atomic-Level Precision for High-Performance Coatings

- What is the function of a Low-Pressure Chemical Vapor Deposition (LPCVD) system in the synthesis of hBN thin films?

- How is CVD utilized in coating applications? Unlock High-Performance Surface Engineering