A major advantage of the chemical vapor sterilizer is its remarkable ability to protect the integrity of your instruments. Unlike methods that rely on high moisture content, it effectively sterilizes without causing rust, dullness, or corrosion on dry metal tools, significantly extending their functional lifespan.

The choice of a sterilization method is not merely about achieving sterility; it is a strategic decision that directly impacts the longevity, performance, and long-term cost of your most valuable instruments.

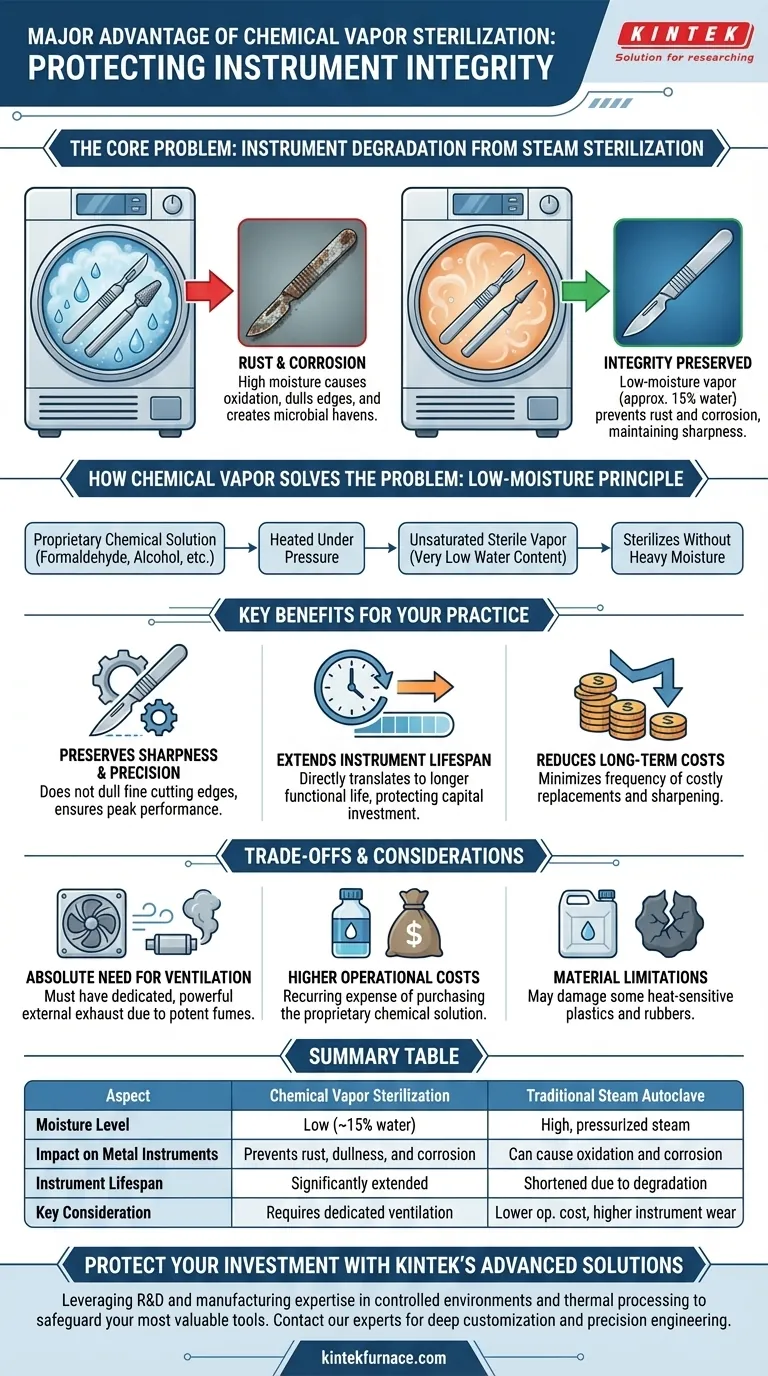

The Core Problem: Instrument Degradation from Sterilization

For any practice that relies on precision metal instruments, maintaining their condition is a constant challenge. The very process designed to ensure safety—sterilization—can often be the cause of their slow destruction.

The Hidden Cost of Corrosion

Corrosion is far more than a cosmetic issue. Rust and pitting on an instrument's surface can create microscopic havens for microorganisms, potentially compromising sterility even after a cycle.

Furthermore, corrosion dulls sharp edges on instruments like scalpels, burs, and curettes, reducing their clinical effectiveness and requiring more frequent, costly sharpening or replacement.

Why Traditional Steam Autoclaves Contribute to the Problem

The most common sterilization method, the steam autoclave, uses pressurized, high-temperature steam. While effective, this combination of intense heat and moisture creates the perfect environment for oxidizing metal.

Carbon steel instruments are particularly vulnerable. Repeated exposure to steam inevitably leads to rust and degradation, shortening their life and diminishing their value.

How Chemical Vapor Solves the Problem

Chemical vapor sterilization, often called "chemiclaving," operates on a fundamentally different principle that directly addresses the weaknesses of steam.

The Principle of Low-Moisture Sterilization

This method uses a proprietary chemical solution—typically containing formaldehyde, alcohol, ketone, and other agents—heated under pressure to create a sterile vapor.

The critical factor is the very low water content (around 15%) in the process. This unsaturated vapor sterilizes without the heavy moisture that causes oxidation, effectively breaking the cycle of rust and corrosion.

Preserving Sharpness and Precision

For instruments where a sharp edge is paramount, this low-moisture environment is a significant advantage. The process does not attack and dull fine cutting edges, ensuring instruments remain at peak performance for much longer.

Extending Instrument Lifespan

By preventing the corrosive damage inherent in steam sterilization, the chemical vapor method directly translates to a longer functional life for your metal instruments. This reduces the frequency of replacements and protects your capital investment over time.

Understanding the Trade-offs and Considerations

No technology is without its limitations. An objective assessment requires acknowledging the specific requirements and potential downsides of chemical vapor sterilization.

The Absolute Need for Ventilation

The chemicals used, particularly formaldehyde, produce potent fumes. Therefore, these sterilizers must be installed in areas with dedicated, powerful ventilation systems that exhaust directly to the outside. This is a critical safety and regulatory requirement, not an option.

Higher Operational Costs

The initial purchase price of a chemical vapor sterilizer can be comparable to an autoclave, but the ongoing operational costs are typically higher. This is due to the recurring expense of purchasing the proprietary chemical solution.

Material and Cycle Limitations

While ideal for metal, chemical vapor may not be suitable for all items. It can damage some heat-sensitive plastics and rubbers. Additionally, the cycle times can be longer than some modern steam autoclaves.

Making the Right Choice for Your Instruments

Selecting a sterilization system requires balancing the goal of absolute sterility with the practical need to protect your instrument investment.

- If your primary focus is preserving high-value, sharp metal instruments: Chemical vapor is the superior choice for maximizing their lifespan and maintaining performance.

- If your primary focus is minimizing upfront costs and chemical handling: A steam autoclave is a proven, economical solution, but you must accept the trade-off of eventual corrosion on certain instruments.

- If your primary focus is safety and compliance: You must be prepared to invest in the necessary ventilation infrastructure before committing to a chemical vapor system.

Ultimately, understanding these distinct advantages and requirements empowers you to select the sterilization method that best aligns with your clinical needs and financial strategy.

Summary Table:

| Aspect | Chemical Vapor Sterilization | Traditional Steam Autoclave |

|---|---|---|

| Moisture Level | Low-moisture process (~15% water) | High-moisture, pressurized steam |

| Impact on Metal Instruments | Prevents rust, dullness, and corrosion | Can cause oxidation and corrosion |

| Instrument Lifespan | Significantly extended | Shortened due to degradation |

| Key Consideration | Requires dedicated ventilation | Lower operational cost, but higher instrument wear |

Protect Your Instrument Investment with KINTEK's Advanced Solutions

Are you seeking to maximize the lifespan and performance of your high-value, precision metal instruments? The challenge of sterilization-induced corrosion is real, but it has a solution.

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide diverse laboratories with advanced thermal processing solutions. Our expertise in creating controlled environments directly translates to understanding the precise demands of sterilization technology.

While chemical vapor sterilization offers a clear advantage for metal preservation, selecting the right equipment is critical. Our product line, including high-performance Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability. We can help you develop or integrate the precise thermal and atmospheric control systems needed for reliable, low-moisture sterilization processes.

Let KINTEK help you safeguard your most valuable tools. Contact our experts today to discuss how our precision engineering can meet your unique sterilization and instrument preservation requirements.

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes