The primary advantage of using Trimethylgallium (TMGa) in MOCVD processes is its exceptionally high vapor pressure. This physical property enables the generation of a high flux of gallium precursors, which is the direct mechanism required to achieve high film growth rates for beta-gallium oxide ($\beta\text{-Ga}_2\text{O}_3$).

Core Takeaway The transition of beta-gallium oxide from the lab to large-scale industrial manufacturing hinges on process efficiency. TMGa is the preferred precursor because its high vapor pressure supports the rapid growth rates necessary for commercially viable device fabrication.

The Critical Role of Vapor Pressure

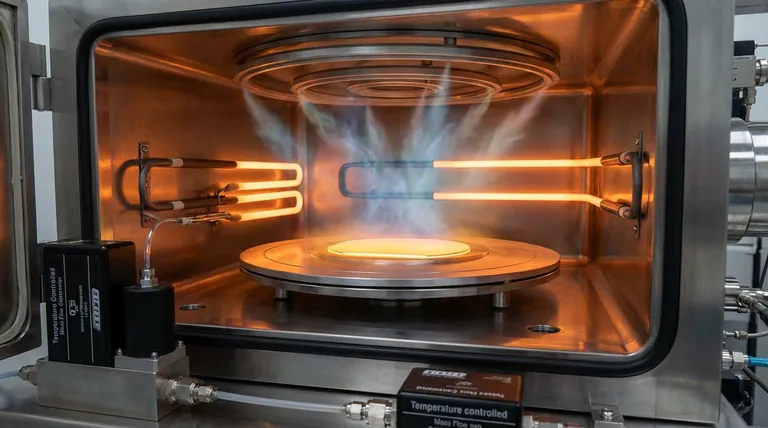

In Metal-Organic Chemical Vapor Deposition (MOCVD), the efficiency of the deposition process is heavily dictated by the physical properties of the source material.

Ensuring Sufficient Gallium Flux

For the chemical reaction to proceed efficiently, the system must be supplied with an adequate amount of reactant.

TMGa possesses an inherently high vapor pressure. This characteristic ensures that a substantial amount of gallium is easily vaporized and transported into the reaction chamber, creating a "sufficient flux" of the precursor.

Driving High Growth Rates

The availability of the precursor directly influences how quickly the crystalline film can be formed.

Because TMGa provides a consistently high flux of gallium, the MOCVD system can sustain high film growth rates. Without this high vapor pressure, the system would be "starved" of gallium, leading to slow, inefficient deposition cycles that are impractical for many applications.

Implications for Industrial Scaling

While laboratory research may tolerate slower processes, commercial viability is determined by throughput.

Bridging the Gap to Manufacturing

The shift from experimental devices to mass production requires processes that are both reliable and fast.

The high growth rates enabled by TMGa are essential for the large-scale industrial manufacturing of $\beta\text{-Ga}_2\text{O}_3$ devices. By reducing the time required to grow thick, high-quality layers, TMGa makes the fabrication process economically feasible.

Understanding the Trade-offs

While high vapor pressure is advantageous for speed, it introduces specific challenges in process control.

Managing High Flux

The benefit of high flux is also a potential liability if not managed with precision.

High vapor pressure sources require robust mass flow controllers and precise temperature management of the bubbler. If the flux becomes excessive or unstable, it can lead to poor crystal quality or pre-reactions in the gas phase, rather than on the substrate surface.

Making the Right Choice for Your Goal

Selecting TMGa is largely a decision driven by the need for efficiency and throughput in the MOCVD process.

- If your primary focus is Industrial Scalability: Prioritize TMGa to maximize throughput and achieve the growth rates required for cost-effective manufacturing.

- If your primary focus is Process Stability: Ensure your MOCVD equipment is rated to handle high-vapor-pressure sources with precise flow control to utilize the high flux without compromising film uniformity.

By leveraging the high vapor pressure of TMGa, you effectively remove the bottleneck of precursor delivery, paving the way for scalable device production.

Summary Table:

| Feature | Advantage of TMGa | Impact on Production |

|---|---|---|

| Vapor Pressure | Exceptionally High | Ensures high precursor flux for rapid reaction |

| Growth Rate | Superior Velocity | Enables thick layer formation in shorter cycles |

| Industrial Readiness | High Throughput | Essential for cost-effective mass manufacturing |

| Precursor Delivery | Efficient Transport | Prevents gallium "starvation" during deposition |

Optimize Your Thin Film Deposition with KINTEK

Achieving the perfect balance of high growth rates and crystal quality in $\beta$-Ga2O3 production requires precision-engineered equipment. KINTEK provides the expertise and advanced hardware needed to manage high-vapor-pressure precursors like TMGa effectively.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD/MOCVD systems, and other lab high-temp furnaces, all customizable for your unique semiconductor research and industrial needs.

Ready to scale your production? Contact us today to discuss your custom furnace requirements!

References

- D. Gogova, Vanya Darakchieva. High crystalline quality homoepitaxial Si-doped <i>β</i>-Ga2O3(010) layers with reduced structural anisotropy grown by hot-wall MOCVD. DOI: 10.1116/6.0003424

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the two primary methods for depositing thin films? Master PVD and CVD for Your Lab

- What is the application of CVD in cutting tools? Boost Tool Life and Machining Efficiency

- What materials are used in CVD? A Guide to High-Performance Thin Films for Your Lab

- What industries commonly use CVD processes? Unlock High-Performance Thin Films for Your Sector

- How does CVD achieve high-purity and uniform films? Master Precise Film Deposition for Superior Results

- How does a CVD furnace work? Master Precision Thin-Film Deposition for Your Lab

- How does a CVD system precisely control InN nanowire growth? Expert Secrets to High-Quality Synthesis

- What types of coating precursors are used in the CVD deposition process? Essential Classes for Superior Film Quality