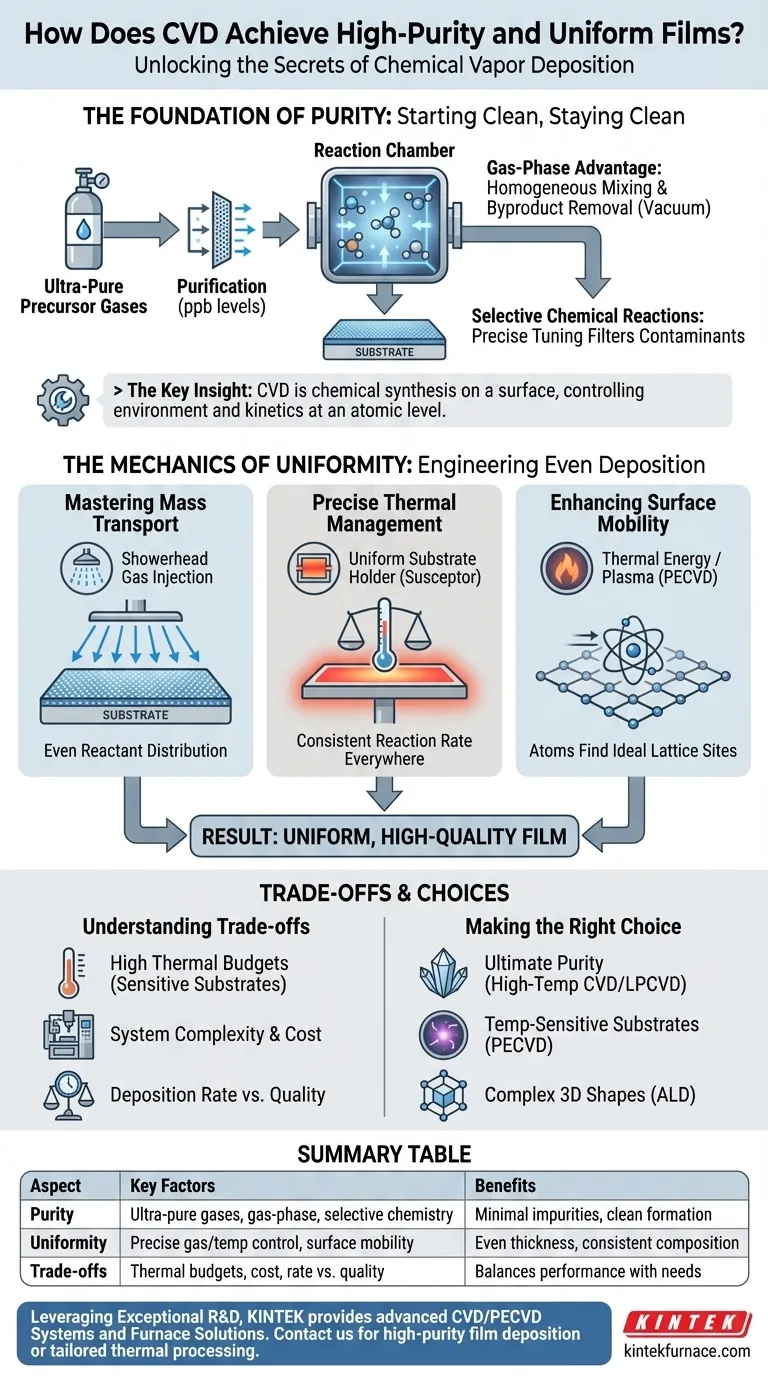

In essence, Chemical Vapor Deposition (CVD) achieves its signature high-purity and uniform films through two core principles: starting with exceptionally pure source materials and then orchestrating a highly controlled chemical reaction directly on the substrate surface. Purity is ensured by using ultra-filtered precursor gases and a reaction environment that prevents contamination, while uniformity comes from precise management of gas flow, temperature, and pressure to guarantee every part of the substrate experiences the same growth conditions.

The key to understanding CVD is to view it not as a simple coating technique, but as a form of chemical synthesis on a surface. Its success in producing high-quality films hinges on controlling the chemical environment and reaction kinetics at an atomic level.

The Foundation of Purity: Starting Clean and Staying Clean

Achieving a film with minimal impurities is a multi-stage process. CVD is designed to prevent contaminants from ever being introduced and to ensure only the desired elements are deposited.

Ultra-Pure Precursor Gases

The process begins long before the material enters the reaction chamber. The precursor gases—the chemical building blocks of the film—are purified to an extraordinary degree, often with impurity levels measured in parts per billion.

By starting with components that are already exceptionally clean, the system inherently avoids introducing contaminants from the source.

The Gas-Phase Advantage

The reaction in a CVD process occurs in the gas phase. Unlike processes involving liquids or solids, gases can be mixed with near-perfect homogeneity.

This ensures that the reactants are evenly distributed and minimizes the risk of unincorporated clusters or foreign particles being trapped in the growing film. The reaction byproducts remain gaseous and are simply removed by the vacuum exhaust system.

Selective Chemical Reactions

CVD relies on a specific chemical reaction that only occurs under a narrow set of conditions (e.g., high temperature). The energy provided is precisely tuned to break the desired chemical bonds in the precursor gases.

This selectivity ensures that only the intended atoms or molecules deposit onto the substrate, forming the film. Undesired gas species or byproducts lack the conditions to react or stick, effectively filtering them out during the deposition process.

The Mechanics of Uniformity: Engineering Even Deposition

Film uniformity, both in thickness and composition, is not an accident. It is the result of meticulous engineering designed to create an identical growth environment across the entire substrate surface.

Mastering Mass Transport

The system must deliver an identical concentration of reactant molecules to every square millimeter of the substrate. This is a challenge of mass transport or fluid dynamics.

Modern CVD reactors often use "showerhead" designs for gas injection. These components distribute the precursor gases evenly over the substrate, preventing areas of high or low concentration that would lead to uneven film thickness.

Precise Thermal Management

The rate of the chemical reaction in CVD is extremely sensitive to temperature. A slight variation of even a few degrees across the substrate can cause a noticeable difference in film thickness.

Therefore, the substrate holder (or "susceptor") is engineered for exceptional temperature uniformity. This ensures the deposition reaction proceeds at the exact same rate everywhere on the surface.

Enhancing Surface Mobility

Once an atom lands on the substrate, it doesn't instantly lock into place. It possesses surface mobility, allowing it to move briefly across the surface to find a low-energy site, such as its proper place in a crystal lattice.

Controlling temperature provides the necessary thermal energy for this movement. Techniques like Plasma-Enhanced CVD (PECVD) use plasma to impart this energy more efficiently, allowing for dense, uniform, and high-quality films at much lower temperatures.

Understanding the Trade-offs

While powerful, CVD is not without its challenges. The pursuit of perfection involves inherent compromises.

High Thermal Budgets

Traditional thermal CVD often requires very high temperatures (600-1200°C) to drive the chemical reactions. This high thermal budget can damage or alter underlying layers in a complex device or be incompatible with temperature-sensitive substrates like plastics.

System Complexity and Cost

The equipment needed to achieve this level of control—high-vacuum systems, precise mass flow controllers, uniform heating elements, and safety protocols for toxic gases—is inherently complex and expensive.

Deposition Rate vs. Quality

Often, the highest quality films require a slower deposition rate. A slower growth gives atoms more time to find their ideal lattice sites, resulting in better crystallinity and fewer defects. This can create a trade-off between film perfection and manufacturing throughput.

Making the Right Choice for Your Goal

The specific variant of CVD you choose depends directly on the balance of quality, material compatibility, and cost your application demands.

- If your primary focus is ultimate purity and crystalline perfection: Standard high-temperature CVD (or a variant like LPCVD) is often the best choice for creating epitaxial layers or flawless dielectric films.

- If your primary focus is depositing on temperature-sensitive substrates: Plasma-Enhanced CVD (PECVD) is the clear solution, as it uses plasma energy to enable high-quality deposition at much lower temperatures.

- If your primary focus is coating complex 3D shapes uniformly: Atomic Layer Deposition (ALD), a sub-class of CVD, provides unparalleled conformity by depositing the film one atomic layer at a time.

By understanding these core principles of purity and uniformity, you can effectively select and optimize a deposition strategy to achieve your specific material goals.

Summary Table:

| Aspect | Key Factors | Benefits |

|---|---|---|

| Purity | Ultra-pure precursor gases, gas-phase reactions, selective chemistry | Minimal impurities, clean film formation |

| Uniformity | Precise gas flow, temperature control, surface mobility | Even thickness, consistent composition across substrate |

| Trade-offs | High thermal budgets, system complexity, deposition rate vs. quality | Balances performance with material compatibility and cost |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need high-purity film deposition or tailored thermal processing, we deliver reliable, efficient solutions to enhance your research and production. Contact us today to discuss how KINTEK can support your specific goals!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs