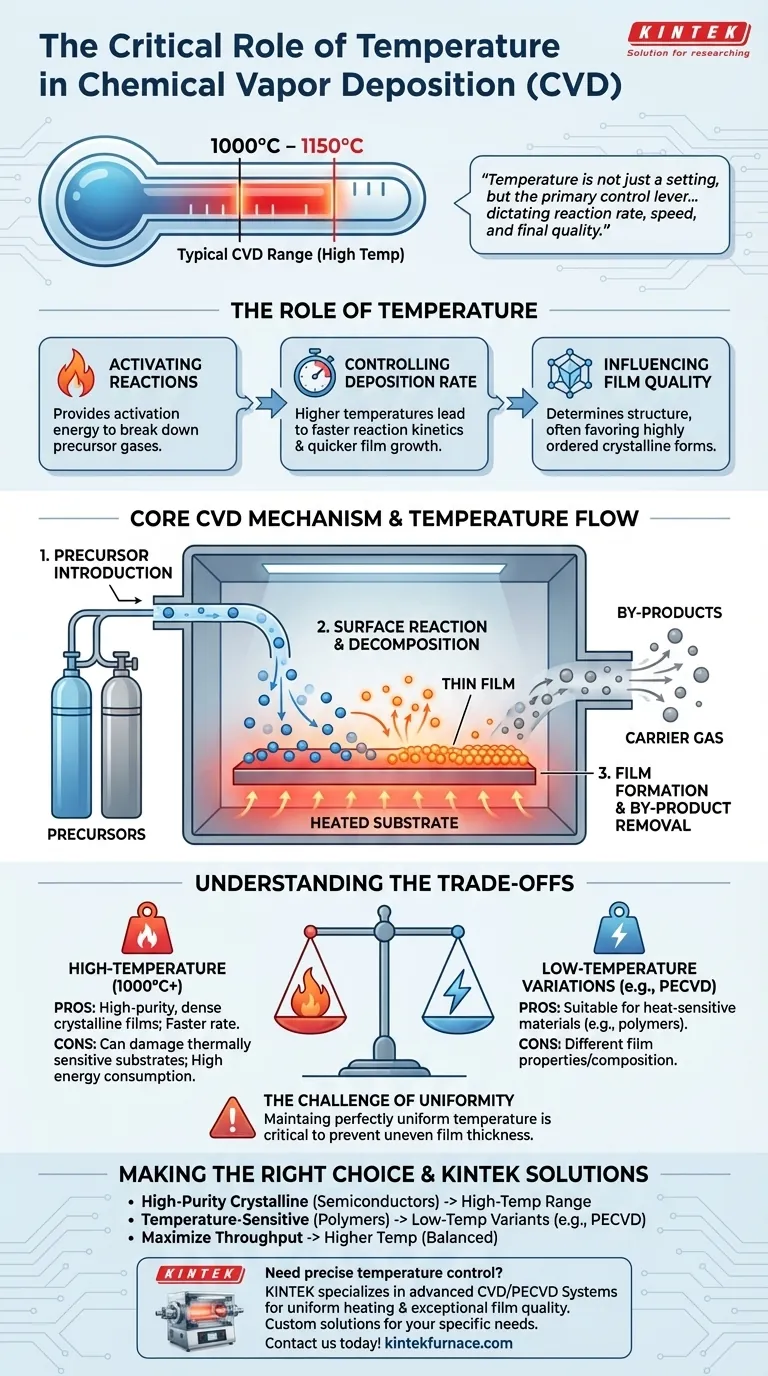

In a typical setup, the Chemical Vapor Deposition (CVD) process operates at high temperatures, generally between 1000°C and 1150°C. This thermal energy is essential for driving the chemical reactions that form the desired thin film on a substrate, and the process is conducted in a neutral gas atmosphere, such as Argon, to prevent unwanted side reactions.

The specific temperature is not just a setting, but the primary control lever in CVD. It directly dictates the rate of the chemical reactions, the speed of film growth, and the final quality and structural properties of the deposited material.

The Role of Temperature in the CVD Process

Temperature is the most critical parameter in a conventional CVD system. It provides the thermal energy required to transform gas-phase chemicals into a solid thin film.

Activating the Chemical Reaction

The high heat within the reaction chamber provides the activation energy needed to break down the precursor gases. Without sufficient temperature, the necessary chemical reactions would not occur, and no film would be deposited.

Controlling Deposition Rate

As a general rule, higher temperatures lead to faster reaction kinetics. This results in a quicker deposition rate, meaning the film grows faster. Conversely, lower temperatures slow the process down, which can sometimes be used to achieve more precise control over film thickness.

Influencing Film Quality

Temperature doesn't just affect the speed of growth; it also determines the final structure of the film. Higher temperatures often provide atoms with enough mobility on the substrate surface to arrange themselves into a highly ordered, crystalline structure, which is crucial for applications like semiconductors.

Understanding the Core CVD Mechanism

The entire CVD process can be understood as three fundamental steps, all of which are governed by the conditions inside the reaction chamber.

Step 1: Introduction of Precursor Gases

A precise mixture of reactive gases, known as precursors, is introduced into the chamber. These gases contain the elements that will make up the final thin film.

Step 2: Surface Reaction and Decomposition

When the precursor gases come into contact with the heated substrate, the thermal energy causes them to react and decompose. This chemical transformation is the heart of the CVD process.

Step 3: Film Formation and By-product Removal

The reaction produces a solid material that deposits, atom by atom, onto the substrate surface, forming a uniform thin film. Gaseous by-products from the reaction are exhausted from the chamber, along with the neutral carrier gas.

Understanding the Trade-offs

The choice of temperature is not arbitrary; it involves a critical balance between process efficiency and material constraints. Choosing the wrong temperature can lead to poor film quality or even damage the substrate.

High-Temperature Deposition

Operating at the upper end of the temperature range (1000°C+) generally produces high-purity, dense, crystalline films at a faster rate. However, these temperatures can damage thermally sensitive substrates and consume significant energy.

Low-Temperature Variations

While traditional CVD is a high-temperature process, specialized variants exist for heat-sensitive materials. Techniques like Plasma-Enhanced CVD (PECVD) use an electric field to energize the precursor gases, allowing deposition to occur at much lower temperatures. The trade-off is often a difference in film properties or composition.

The Challenge of Uniformity

Maintaining a perfectly uniform temperature across the entire substrate is a major engineering challenge. Any temperature variations can cause the film to grow thicker in hotter spots and thinner in cooler spots, compromising the quality of the final product.

Making the Right Choice for Your Goal

The ideal temperature is determined by your specific objective and the materials you are working with.

- If your primary focus is high-purity crystalline films for semiconductors: You will operate in the traditional high-temperature range (1000°C+) to achieve the required material structure and quality.

- If your primary focus is depositing on temperature-sensitive substrates like polymers: You must use a low-temperature CVD variant, where energy is supplied by a source other than heat, such as plasma.

- If your primary focus is maximizing manufacturing throughput: Higher temperatures are generally preferred for faster deposition, but this must be balanced against energy costs and the thermal limits of your substrate.

Ultimately, mastering the CVD process comes from understanding temperature as a fundamental tool for controlling chemical reactions at the atomic scale.

Summary Table:

| Aspect | Details |

|---|---|

| Typical Temperature Range | 1000°C to 1150°C |

| Key Role | Activates reactions, controls deposition rate, influences film structure |

| High-Temperature Effects | Faster deposition, high-purity crystalline films |

| Low-Temperature Options | PECVD for heat-sensitive substrates |

| Critical Factor | Balances efficiency and material constraints |

Need precise temperature control for your CVD processes? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD Systems, designed to deliver uniform heating and exceptional film quality. With our strong R&D and deep customization capabilities, we tailor systems to meet your unique experimental needs—whether for semiconductors, polymers, or other materials. Contact us today to enhance your lab's performance with reliable, efficient equipment!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision