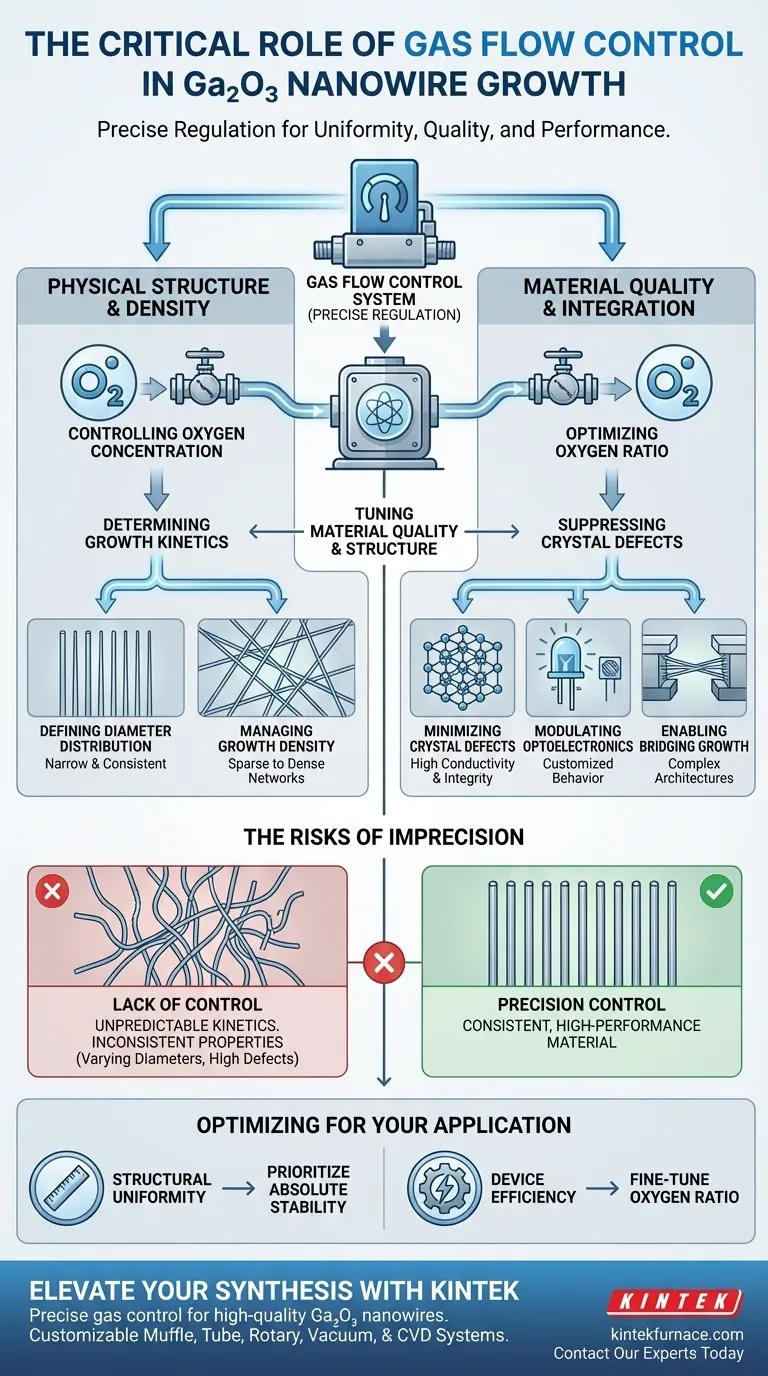

Precise regulation of the growth environment is the critical function of the gas flow control system in Gallium Oxide (Ga2O3) nanowire fabrication. By accurately managing the oxygen concentration, this system directly dictates the growth kinetics, establishing the nanowires' physical structure and quality. Without this control, it is impossible to achieve the specific optoelectronic properties required for high-performance applications.

The gas flow control system acts as the primary mechanism for tuning material quality, establishing a direct link between oxygen ratios and the nanowire’s diameter, density, and defect levels.

Regulating the Growth Environment

Controlling Oxygen Concentration

The fundamental role of the gas flow system is the high-precision regulation of oxygen concentration within the reaction chamber. This ratio is not merely a background condition; it is an active variable that drives the chemical synthesis of the material.

Determining Growth Kinetics

The concentration of oxygen, determined by the flow rate, governs the rate and manner in which the nanowires form. This influence on growth kinetics is the lever researchers use to shape the final product.

Impact on Physical Structure

Defining Diameter Distribution

The flow of gas directly impacts the thickness of the resulting nanowires. Precise control allows for a narrow diameter distribution, ensuring that the nanowires are uniform in size.

Managing Growth Density

Beyond individual wire size, the gas flow dictates the population density of the nanowires on the substrate. Adjusting the flow enables the transition between sparse, isolated growth and dense, interconnected networks.

Enhancing Material Quality and Integration

Minimizing Crystal Defects

The stability of the gas flow is directly correlated to the purity of the crystal lattice. An optimized oxygen ratio suppresses the formation of crystal defects, which is essential for maintaining high conductivity and structural integrity.

Modulating Optoelectronic Characteristics

Because the gas flow influences defect levels and geometry, it effectively tunes the optoelectronic behavior of the nanowires. This allows the material to be customized for specific light-emitting or sensing applications.

Enabling Bridging Growth

Achieving high-performance "bridging growth"—where nanowires span a gap between structures—requires exacting environmental conditions. The gas flow system provides the stability necessary to facilitate this complex architectural feat.

The Criticality of Precision

The Risks of Imprecision

While high precision yields high performance, the inverse is also true. A lack of control over the gas flow results in unpredictable growth kinetics.

Inconsistent Material Properties

If the oxygen ratio fluctuates, the resulting nanowires will suffer from varying diameters and high defect densities. This renders them unsuitable for integration into sensitive electronic devices.

Optimizing for Your Specific Application

To achieve the best results, you must tailor your gas flow strategy to your specific engineering goals.

- If your primary focus is structural uniformity: Prioritize absolute stability in flow rates to narrow the diameter distribution and ensure consistent geometry across the substrate.

- If your primary focus is device efficiency: Fine-tune the oxygen ratio to minimize crystal defects, thereby maximizing the specific optoelectronic characteristics required for your device.

By treating the gas flow control system as a precision tuning instrument rather than a simple supply line, you unlock the full potential of Ga2O3 nanowire technology.

Summary Table:

| Key Role | Impact on Nanowire Growth | Primary Benefit |

|---|---|---|

| Oxygen Regulation | Drives chemical synthesis & kinetics | Consistent material purity |

| Flow Rate Stability | Defines diameter & density distribution | Structural uniformity |

| Defect Suppression | Minimizes lattice inconsistencies | High-performance optoelectronics |

| Environment Tuning | Facilitates complex bridging growth | Advanced device integration |

Elevate Your Material Synthesis with KINTEK

Precise gas control is the foundation of high-quality Gallium Oxide nanowires. At KINTEK, we understand that stability and accuracy are non-negotiable for advanced research. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory requirements.

Ready to optimize your growth kinetics and minimize crystal defects? Partner with KINTEK for reliable high-temperature solutions tailored to your specific engineering goals.

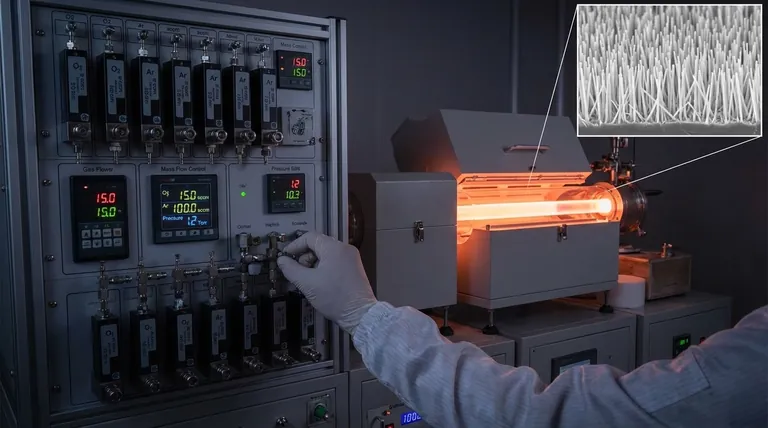

Visual Guide

References

- Bing Bai, Shunji Chen. Growth Optimization of Bridging Ga<sub>2</sub>O<sub>3</sub> Nanowires and the Effect of Oxygen on their Optoelectronic Properties. DOI: 10.1002/pssa.202500163

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What process conditions does CVI equipment provide for optimizing ceramic honeycombs? Enhance Microwave Absorption

- How does the CVD process work in depositing materials onto substrates? Master Thin-Film Deposition for Superior Materials

- What is Chemical Vapor Deposition (CVD)? Unlock High-Purity Thin Film Solutions

- Why is a high vacuum magnetron sputtering system required for NiO layers? Ensure Chemical Purity and Conductivity

- What process control is achieved through automatic butterfly and needle valves in CVD? Master Precise Chamber Stability

- What is the function of the External Heating Tape in 2D In2Se3 CVD? Master Precursor Control for Precision Synthesis

- What is a Chemical Vapor Deposition (CVD) furnace used for? Precision Thin Films for Electronics & Materials

- How do gas diffusers contribute to the CVD process? Ensure Uniform Film Growth and High Yield