In short, a Chemical Vapor Deposition (CVD) furnace is a highly controlled, high-temperature system used to create ultra-thin, high-performance films or coatings on the surface of a substrate. It does this by introducing specific gases (precursors) that react and decompose within the furnace, depositing a solid material atom by atom onto the target object. This process is fundamental to manufacturing modern electronics and advanced materials.

A CVD furnace is not just for applying a simple coating; it is a precision instrument for building materials from the ground up. It enables the fabrication of complex, multi-layered structures with atomic-level control, which is why it is indispensable for creating semiconductors, solar cells, and wear-resistant components.

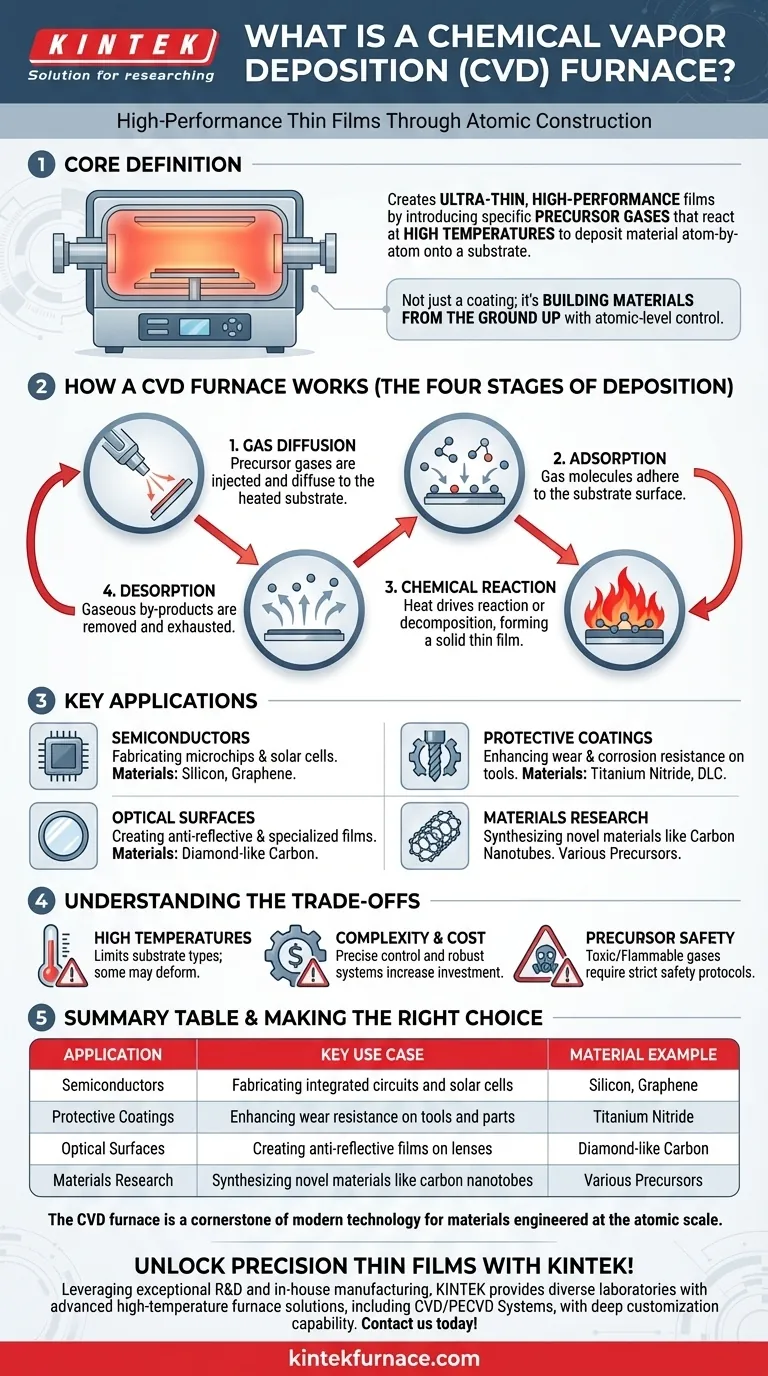

How a CVD Furnace Works

Understanding CVD requires thinking of it as a form of "atomic construction" rather than simple coating. The furnace creates the perfect environment for chemical reactions to build a new solid layer from a gaseous state.

The Core Principle: Building with Gas

The process begins with a substrate, which is the base material to be coated (like a silicon wafer or a machine tool). This substrate is placed inside the furnace's reaction chamber.

The goal is to deposit a new material, such as silicon or graphene, onto this substrate. Instead of using a solid or liquid form of the new material, CVD uses a precursor gas that contains the necessary chemical elements.

The Four Stages of Deposition

The deposition itself occurs in a precise, four-stage sequence that is carefully controlled by the furnace's temperature and pressure settings.

- Gas Diffusion: Precursor gases are injected into the chamber and diffuse toward the heated substrate.

- Adsorption: The gas molecules land and are adsorbed onto the substrate's surface.

- Chemical Reaction: The intense heat of the furnace provides the energy for the precursor gases to react or decompose, leaving behind the desired solid material as a thin film.

- Desorption: Gaseous by-products from the reaction are then removed from the surface and exhausted from the chamber, leaving only the pure, solid film behind.

This cycle repeats to build the film layer by layer, ensuring complete coverage and highly controlled thickness across the entire substrate.

Key Applications of CVD

The ability to create high-purity, uniform thin films makes CVD a critical process in numerous high-tech industries.

Fabricating Semiconductors

This is the most well-known application. CVD is used to deposit various materials like silicon, silicon nitride, and graphene onto wafers to build the intricate, multi-layered structures of integrated circuits (microchips) and photovoltaic cells for solar panels.

Creating Protective Coatings

CVD is used to apply exceptionally hard and durable coatings, such as titanium nitride or diamond-like carbon, onto cutting tools, bearings, and engine parts. These coatings dramatically improve wear resistance and protect against corrosion and oxidation, extending component lifespan.

Engineering Optical Surfaces

The process allows for the deposition of thin films with precise optical properties. This is used to create anti-reflective coatings on lenses, specialized films on mirrors, and other components used in lasers and advanced optical systems.

Advancing Materials Research

In laboratory settings, CVD furnaces are workhorses for innovation. Researchers use them to synthesize novel materials like carbon nanotubes and graphene, study the behavior of catalysts, and develop new types of materials with unique electronic or structural properties.

Understanding the Trade-offs

While powerful, the CVD process has inherent complexities and limitations that are important to recognize.

Requirement for High Temperatures

Traditional CVD often requires very high temperatures (several hundred to over a thousand degrees Celsius) to drive the chemical reactions. This can limit the types of substrate materials that can be used, as some may deform or melt.

Complexity and Cost

A CVD system is not simple equipment. It requires precise control over gas flow rates, temperature, and pressure, along with robust vacuum and exhaust systems. This makes the initial investment and operational costs significant.

Handling of Precursor Gases

The precursor gases used in CVD can be toxic, flammable, or corrosive. This necessitates sophisticated safety protocols, sensors, and handling procedures, adding to the operational complexity.

Making the Right Choice for Your Goal

Your application will determine if the precision of CVD is necessary and worth the investment.

- If your primary focus is electronics manufacturing: CVD is non-negotiable for depositing the high-purity, uniform layers essential for modern semiconductor fabrication.

- If your primary focus is mechanical durability: CVD provides superior, atomically bonded coatings that offer unmatched hardness and corrosion resistance for high-performance tools and parts.

- If your primary focus is advanced materials research: A CVD furnace is a fundamental tool for synthesizing and exploring the properties of next-generation materials.

Ultimately, the CVD furnace is a cornerstone of modern technology, enabling the creation of materials that are engineered at the atomic scale for peak performance.

Summary Table:

| Application | Key Use Case | Material Example |

|---|---|---|

| Semiconductors | Fabricating integrated circuits and solar cells | Silicon, Graphene |

| Protective Coatings | Enhancing wear resistance on tools and parts | Titanium Nitride |

| Optical Surfaces | Creating anti-reflective films on lenses | Diamond-like Carbon |

| Materials Research | Synthesizing novel materials like carbon nanotubes | Various Precursors |

Unlock the potential of precision thin films for your lab! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including CVD/PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our CVD furnaces can enhance your research and production efficiency!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab