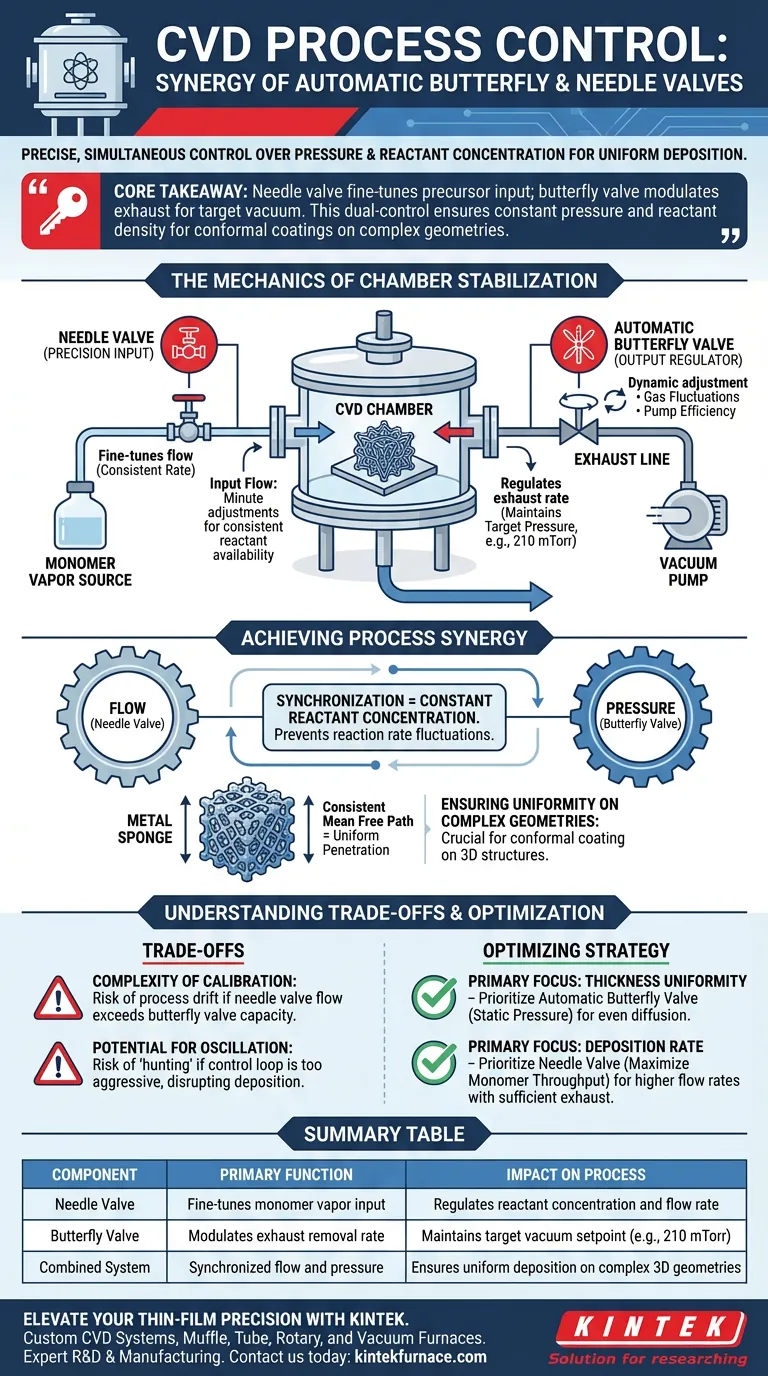

The combination of automatic butterfly valves and needle valves achieves precise, simultaneous control over chamber pressure and reactant concentration in Chemical Vapor Deposition (CVD) processes. By balancing the rate at which monomer vapors enter the chamber against the rate at which exhaust is removed, this system creates a stable reaction environment capable of uniform deposition.

Core Takeaway While the needle valve fine-tunes the input of chemical precursors, the butterfly valve modulates the exhaust to maintain a specific vacuum setpoint. This dual-control mechanism is critical for ensuring constant total pressure and reactant density, which are required to achieve conformal coatings on complex, three-dimensional geometries.

The Mechanics of Chamber Stabilization

The Role of the Needle Valve

The needle valve serves as the precision input control for the system. Its primary function is to fine-tune the flow of monomer vapors into the heated vacuum chamber.

By making minute adjustments to the aperture, the needle valve regulates the exact amount of precursor gas introduced to the process. This ensures that the chemical reactants are available at a consistent rate for decomposition.

The Role of the Automatic Butterfly Valve

The automatic butterfly valve acts as the output regulator, positioned on the exhaust line. It actively regulates the exhaust rate to maintain the chamber's operating pressure at a specific target, such as 210 mTorr.

As gas flow fluctuates or as the vacuum pump's efficiency varies, the butterfly valve automatically opens or closes. This dynamic adjustment counters external variables to lock in the target pressure.

Achieving Process Synergy

Maintaining Constant Reactant Concentration

The true value of this system lies in the synchronization of the two valves. Merely controlling flow or pressure in isolation is insufficient for high-quality CVD.

By using the needle valve to set the flow and the butterfly valve to set the pressure, the system ensures a constant reactant concentration. This stability prevents fluctuations in the chemical reaction rate, which is vital for predictable results.

Ensuring Uniformity on Complex Geometries

When pressure and flow are stabilized, the mean free path of the gas molecules becomes consistent. This allows the precursor gas to penetrate and react evenly across all surfaces.

This is particularly important for conformal coating on three-dimensional structures, such as metal sponges. Without this precise control, internal geometries or intricate details might receive uneven coating thicknesses or no coating at all.

Understanding the Trade-offs

Complexity of Calibration

While this dual-valve approach offers superior control, it introduces complexity in process tuning. If the needle valve allows too much flow, the butterfly valve may open fully but fail to maintain the low-pressure target (e.g., 210 mTorr), leading to process drift.

Potential for Oscillation

Because the butterfly valve reacts to pressure changes, there is a risk of "hunting" or oscillation if the control loop is too aggressive.

If the valve over-corrects, the pressure will constantly swing above and below the setpoint. This instability can disrupt the deposition rate, leading to layered or inconsistent film properties rather than a homogenous coating.

Optimizing Your Deposition Strategy

To leverage this control system effectively, align your valve settings with your specific output requirements:

- If your primary focus is thickness uniformity: Prioritize the automatic butterfly valve settings to ensure pressure remains absolutely static, facilitating even diffusion into complex shapes.

- If your primary focus is deposition rate: Focus on optimizing the needle valve to maximize monomer throughput, ensuring the exhaust system has enough overhead to maintain vacuum at higher flow rates.

Mastering the interplay between input flow and exhaust throttling is the key to transforming a standard CVD process into a high-precision manufacturing tool.

Summary Table:

| Component | Primary Function | Impact on Process |

|---|---|---|

| Needle Valve | Fine-tunes monomer vapor input | Regulates reactant concentration and flow rate |

| Butterfly Valve | Modulates exhaust removal rate | Maintains target vacuum setpoint (e.g., 210 mTorr) |

| Combined System | Synchronized flow and pressure | Ensures uniform deposition on complex 3D geometries |

Elevate Your Thin-Film Precision with KINTEK

Achieving perfect conformal coatings requires more than just high-quality valves; it demands a flawlessly integrated system. KINTEK provides industry-leading R&D and manufacturing expertise, offering a comprehensive range of CVD systems, Muffle, Tube, Rotary, and Vacuum furnaces—all fully customizable to meet your specific process requirements.

Whether you are coating complex metal sponges or developing next-generation materials, our expert team is ready to help you optimize your deposition strategy. Contact KINTEK today to discuss your unique needs and discover how our advanced laboratory high-temperature solutions can enhance your manufacturing precision.

Visual Guide

References

- Hunter O. Ford, Megan B. Sassin. Non-line-of-sight synthesis and characterization of a conformal submicron-thick cationic polymer deposited on 2D and 3D substrates. DOI: 10.1039/d3lf00256j

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the purpose of methane in CVD graphene growth? Master the Key Carbon Source for High-Quality Graphene

- Why is Ar/H2 Flow Control Critical for V2O5 Nanosheet CVD? Master Redox Potential and Morphology

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth

- What are the safety concerns associated with CVD processes? Mitigate Risks with Expert Solutions

- What is a CVD furnace? A Precision Tool for Building Advanced Materials

- What are the advantages of CVD over PVD? Superior Conformality for Complex Shapes

- What are the different substrate heating methods in CVD? Hot Wall vs. Cold Wall Explained

- What is MOCVD used for? Powering LEDs, Lasers, and 5G with Atomic Precision